Roller sliding wire

A slip line and roller technology, applied to roller slip lines. It can solve the problems of arcing, thermal deformation and frequent replacement cycles of the skateboard, and achieve the effect of smooth power supply.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

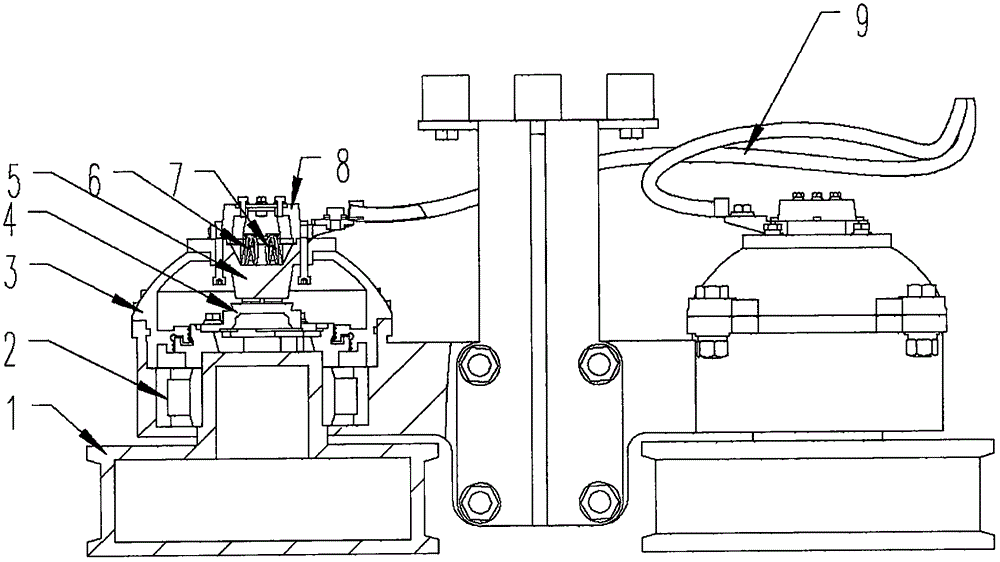

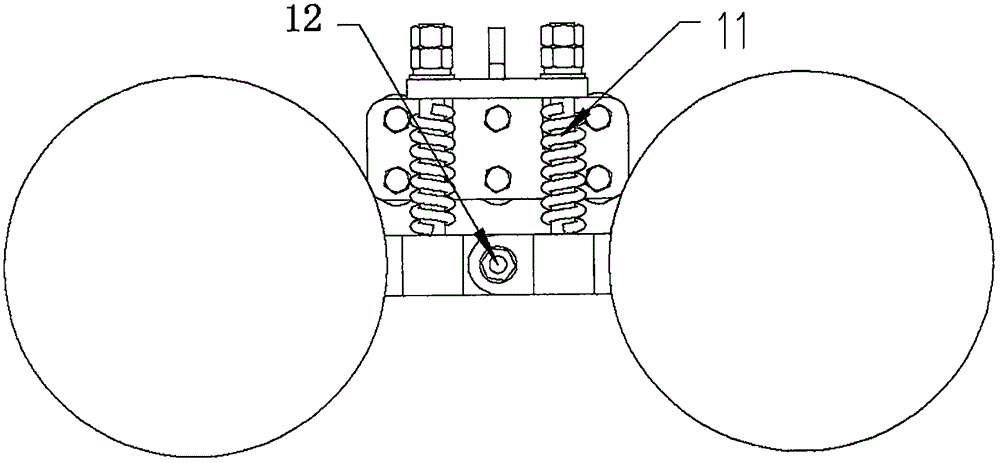

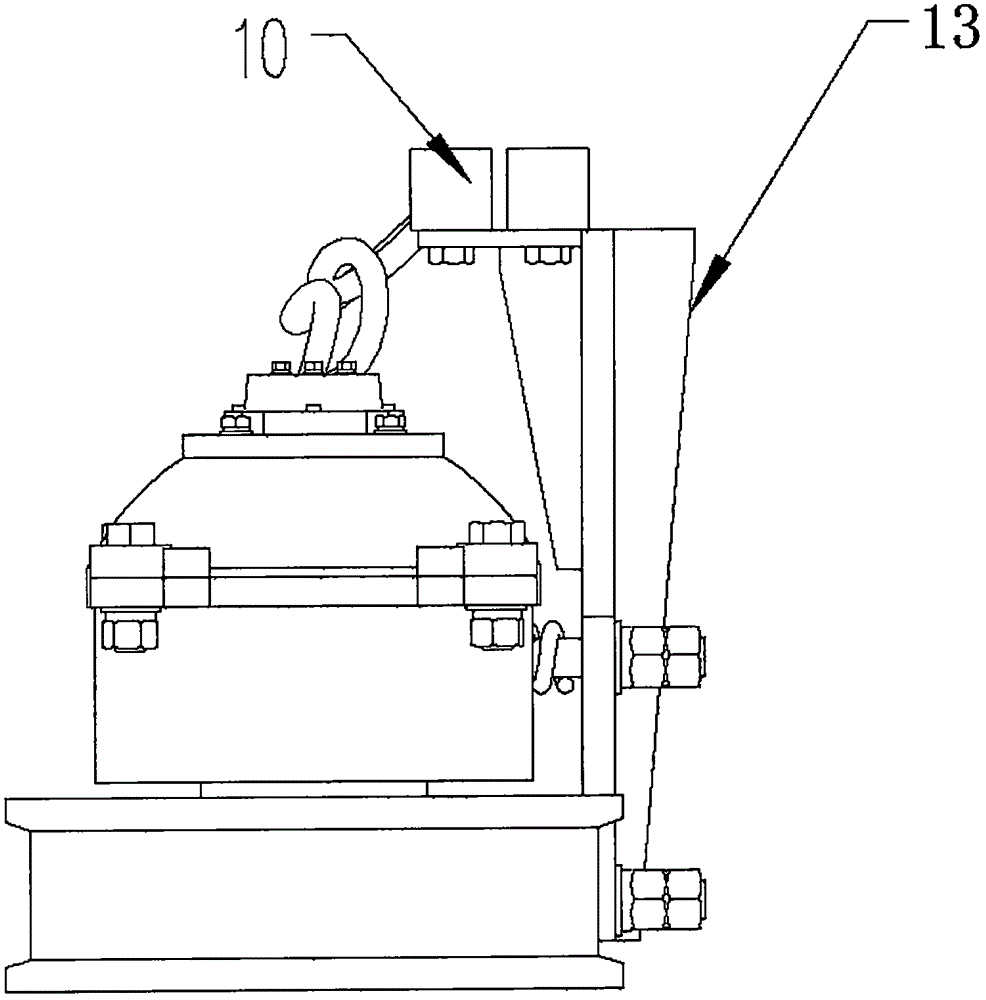

[0020] see Figure 1~3 , in an embodiment of the present invention, a roller slide line includes a conductive wheel 1, a conductive plate 4, a brush holder 5, a brush 6, a constant voltage compression spring 7, and an outer conductor 8; the conductive wheel 1 is mounted on the bearing 2 On the casing 3, the conductive wheel 1 is in rolling contact with the guide rail, and the conductive wheel 1 can roll freely; the conductive plate 4 is installed on the conductive wheel 1 and is in contact with the brush 6, and the conductive wheel 1 is rolled to make the conductive plate 4 and the brush 6 forms rolling friction, prevents the cable from being twisted, and can effectively conduct current for a long time. Due to the rolling of the conductive wheel 1, the conductive plate 4 and the brush 6 form rolling friction, so the wear of the brush 6 is very small, and the brush 6 can be avoided. Manual replacement can be used for a long time, saving manpower and energy, and at the same time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com