Talcum powder feeding device and talcum powder feeding method for powdery emulsion explosive

A technology of powder emulsion explosive and feeding device, which is applied to explosive processing equipment, explosives, transportation and packaging, etc., can solve problems such as endangering people's lives, unfavorable production safety, hidden dangers of explosives, etc., and achieves low manufacturing cost, easy operation, Guarantee the effect of safe production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with the accompanying drawings, the technical solutions in the present invention are clearly and completely described. The described embodiments are only a part of the present invention. All other inventions and creations obtained belong to the protection scope of the present invention.

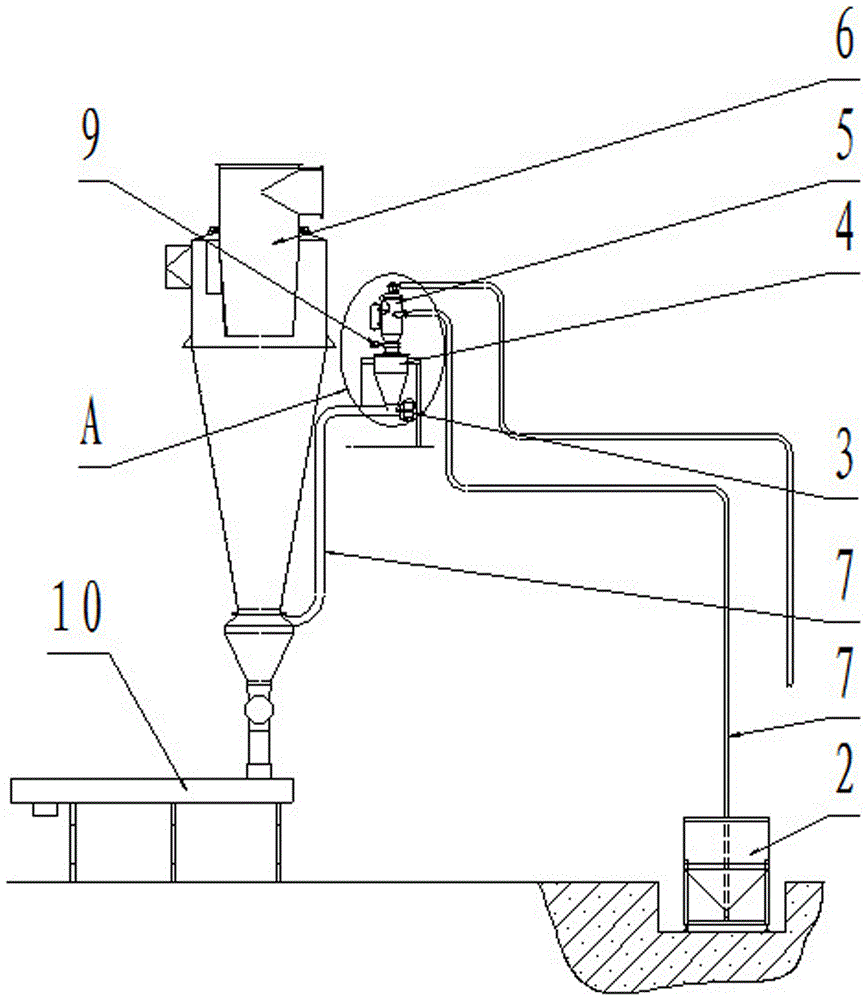

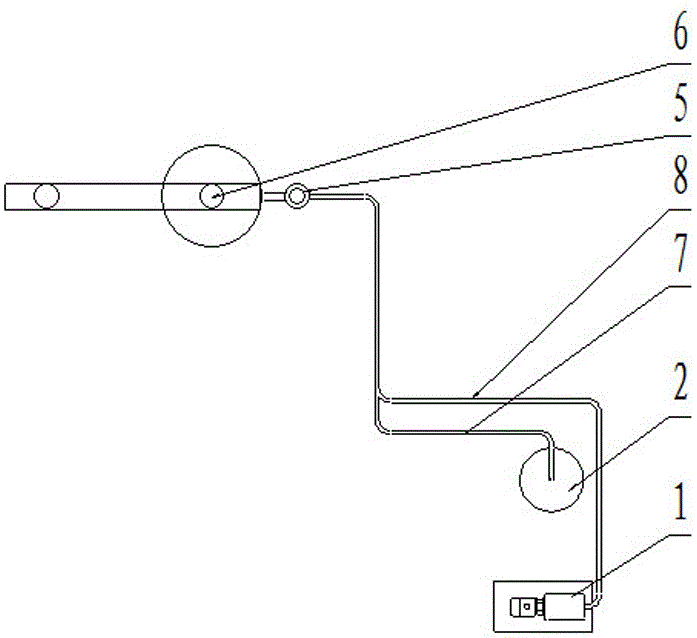

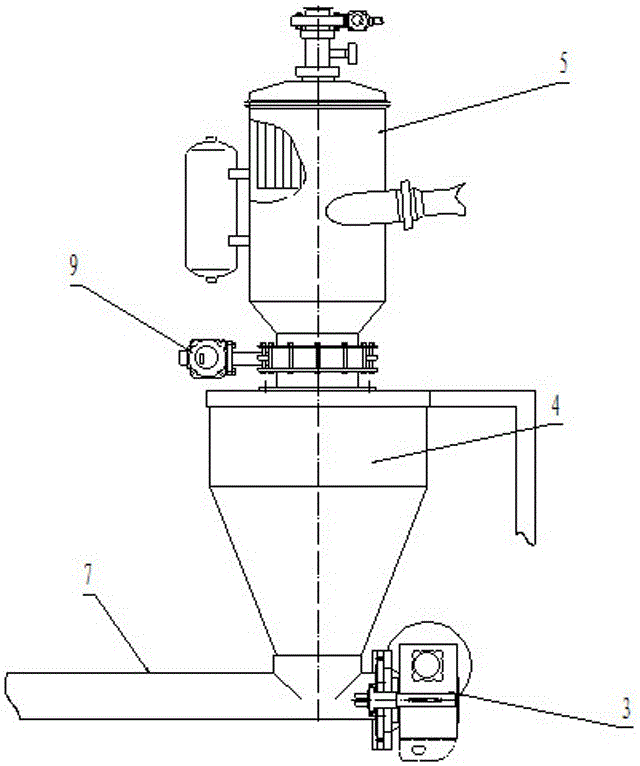

[0019] Depend on figure 1 , figure 2 , image 3 It can be seen that the talcum powder feeding device of a powdery emulsion explosive in this embodiment is composed of a vacuum pump 1, a feeding bin 2, a quantitative screw conveyor 3, a buffer bin 4, a vacuum feeding machine 5, a cyclone separator 6 and a hose 7. . The vacuum pump 1 of the present embodiment is connected with the vacuum feeder 5 through the suction pipe 8, the feeding bin 2 is connected with the vacuum feeder 5 through the hose 7, the vacuum feeder 5 is connected with the buffer bin 4 through the pneumatic valve 9, and the quantitative screw conveyor 3 and the buffer bin 4 are connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com