PP (polypropylene) internal spiral pipe for drainage and preparation method of PP internal spiral pipe

A polypropylene material and polypropylene technology, applied in the field of polypropylene inner spiral pipe for drainage and its preparation, can solve the problem of unreasonable design of height and pitch distance, poor physical and chemical properties of the pipe, and influence on the drainage and sound-absorbing performance of the pipe, etc. problems, to achieve the effects of improving physical and chemical properties, reducing the drag coefficient of the water tongue, and stabilizing pressure fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for preparing a polypropylene internal spiral pipe for drainage, comprising the steps of:

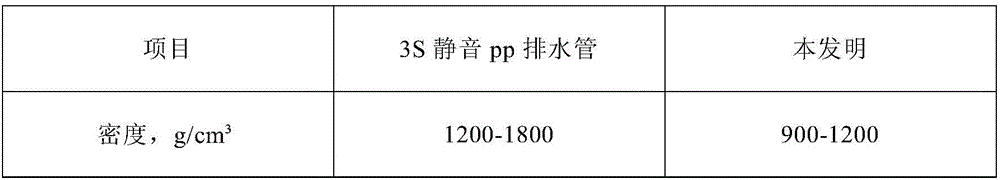

[0028] Step 1), raw material mixing: mix the raw materials according to the weight ratio: 30 parts of polypropylene PP pellets, 50 parts of barium sulfate, 18 parts of montmorillonite, 2 parts of dispersant, put them in a high-speed mixer for high-temperature mixing, mix The temperature of the mixture is 120-150°C. After mixing for 30-40 minutes, the mixture is semi-gelled. At this time, the temperature of the mixture is as high as 120-125°C. Put the mixture into the cold mixer and continue mixing until it cools down to 40- Stop at 50°C;

[0029] Step 2), granulation: the material collected in step 1) is sent into a granulator for granulation to obtain pellets;

[0030] Step 3), pipe making: put the pellets obtained in step 2) into the barrel after cooling, the barrel has five temperature sections, the temperature at the inlet end of the barrel is 190-200°C, and the tem...

Embodiment 2

[0032] A method for preparing a polypropylene internal spiral pipe for drainage, comprising the steps of:

[0033] Step 1), raw material mixing: mix the raw materials according to the weight ratio: 25 parts of polypropylene PP pellets, 60 parts of barium sulfate, 13 parts of montmorillonite, 2 parts of dispersant, put them in a high-speed mixer for high-temperature mixing, mix The temperature of the mixture is 120-150°C. After mixing for 30-40 minutes, the mixture is semi-gelled. At this time, the temperature of the mixture is as high as 120-125°C. Put the mixture into the cold mixer and continue mixing until it cools down to 40- Stop at 50°C;

[0034] Step 2), granulation: the material collected in step 1) is sent into a granulator for granulation to obtain pellets;

[0035] Step 3), pipe making: put the pellets obtained in step 2) into the barrel after cooling, the barrel has five temperature sections, the temperature at the inlet end of the barrel is 190-200°C, and the tem...

Embodiment 3

[0037] A method for preparing a polypropylene internal spiral pipe for drainage, comprising the steps of:

[0038] Step 1), raw material mixing: mix the raw materials according to the weight ratio: 28 parts of polypropylene PP pellets, 55 parts of barium sulfate, 15 parts of montmorillonite, 2 parts of dispersant, put them in a high-speed mixer for high-temperature mixing, mix The temperature of the mixture is 120-150°C. After mixing for 30-40 minutes, the mixture is semi-gelled. At this time, the temperature of the mixture is as high as 120-125°C. Put the mixture into the cold mixer and continue mixing until it cools down to 40- Stop at 50°C;

[0039] Step 2), granulation: the material collected in step 1) is sent into a granulator for granulation to obtain pellets;

[0040] Step 3), pipe making: put the pellets obtained in step 2) into the barrel after cooling, the barrel has five temperature sections, the temperature at the inlet end of the barrel is 190-200°C, and the tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com