Alkaline-earth sulfide luminescent material, preparation method and application of material

A technology of luminescent materials and sulfides, used in luminescent materials, chemical instruments and methods, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

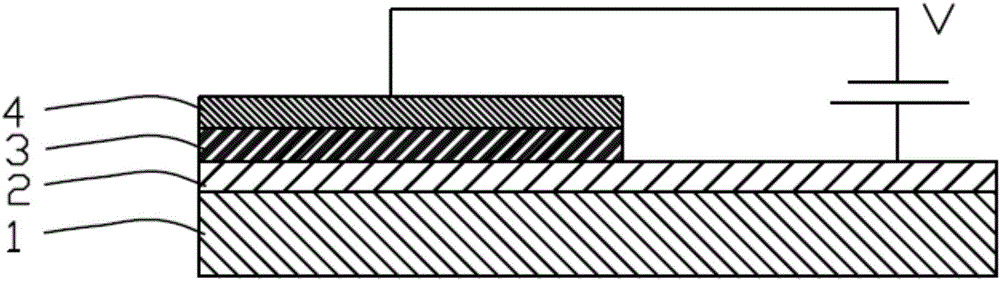

[0034] The preparation method of the above-mentioned alkaline earth sulfide luminescent material comprises the following steps:

[0035] Step S11, according to MeS: xCe 3++ The stoichiometric ratio of each element is weighed, wherein, x is 0.01-0.08, and Me is at least one selected from magnesium, calcium, strontium and barium.

[0036] Step S12, the organic source selects cyclopentadiene alkaline earth salt C respectively 5 h 5 ) 2 Me, hydrogen sulfide H 2 S and Tetramethylheptanedionate Ce(TMHD) 4 , where cyclopentadiene alkaline earth salt C 5 h 5 ) 2 Me and Tetramethylheptanedionate Ce(TMHD) 4 , the molar ratio is (1-x):x, and the vacuum degree of the chamber is pumped to 1.0×10 with a mechanical pump and a molecular pump -2 Pa~1.0×10 -3 Pa, the substrate is heat-treated at 700°C for 10-30 minutes, the rotation speed of the substrate holder is adjusted to 50-1000 rpm, and the carrier gas Ar gas is introduced at a flow rate of 5-15 sccm, and then oxygen is introdu...

Embodiment 1

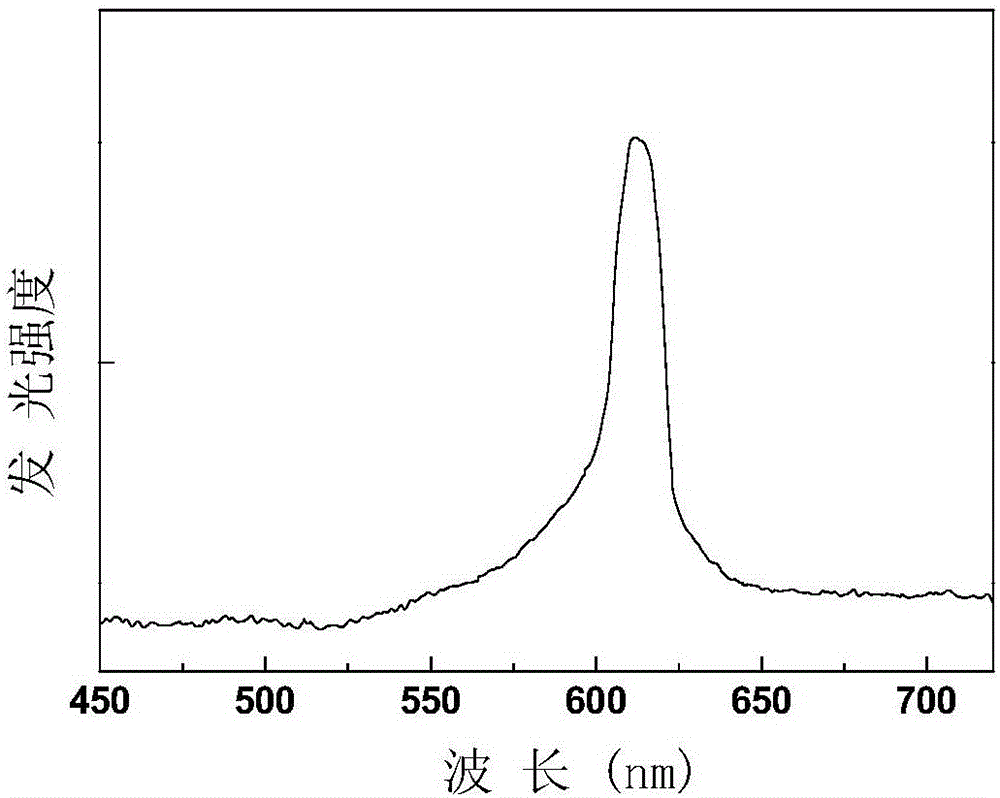

[0050] Example 1: The substrate is ITO glass purchased by CSG, and it is ultrasonically cleaned with toluene, acetone and ethanol for 5 minutes, then rinsed with distilled water, air-dried with nitrogen, and sent to the reaction chamber of the equipment. Use a mechanical pump and a molecular pump to evacuate the vacuum of the chamber to 4.0×10 -3 Pa; Then the substrate is heat-treated at 700°C for 20 minutes, and then the temperature is lowered to 500°C. Turn on the rotating motor, adjust the rotating speed of the substrate holder to be 300 rpm, and feed cyclopentadiene alkaline earth salt C 5 h 5 ) 2 Mg, tetramethylheptanedionate cerium Ce (TMHD) 4 The carrier gas Ar gas has a molar flow ratio of 0.95:0.05 and a flow rate of 10 sccm. Introduce hydrogen sulfide H 2 S, the flow rate is 120 sccm, and the film deposition starts. The thickness of the film is deposited to 150nm, close the organic source and carrier gas, continue to pass oxygen, the temperature drops below 100...

Embodiment 2

[0051] Example 2: The substrate is ITO glass purchased by CSG, which is ultrasonically cleaned with toluene, acetone and ethanol for 5 minutes, then rinsed with distilled water, air-dried with nitrogen, and sent to the reaction chamber of the equipment. Use a mechanical pump and a molecular pump to evacuate the vacuum of the chamber to 1.0×10 -3 Pa; Then the substrate is heat-treated at 700°C for 10 minutes, and then the temperature is lowered to 250°C. Turn on the rotating motor, adjust the rotating speed of the substrate holder to be 50 rpm, and feed cyclopentadiene alkaline earth salt C 5 h 5 ) 2 Mg, tetramethylheptanedionate cerium Ce (TMHD) 4 The carrier gas Ar gas, its molar flow ratio is 0.92:0.08, hydrogen sulfide H 2 S, the flow rate is 10 sccm, and the film deposition starts. The thickness of the film is deposited to 80nm, close the organic source and carrier gas, continue to pass oxygen, the temperature drops below 100°C, take out the sample MgS: 0.08Ce 3+ ....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com