Nitrobacterium continuous production method and production equipment thereof

A technology of nitrifying bacteria and production methods, applied in the direction of sterilization methods, microorganism-based methods, biochemical equipment and methods, etc., can solve the problems of cumbersome process, unfavorable long-term storage, and impurity of ammonia oxidizing bacteria, so as to prevent random The effects of effluent loss, increased bacteria attachment rate, and simple storage method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] NB1 commercially available nitrifying bacteria culture process

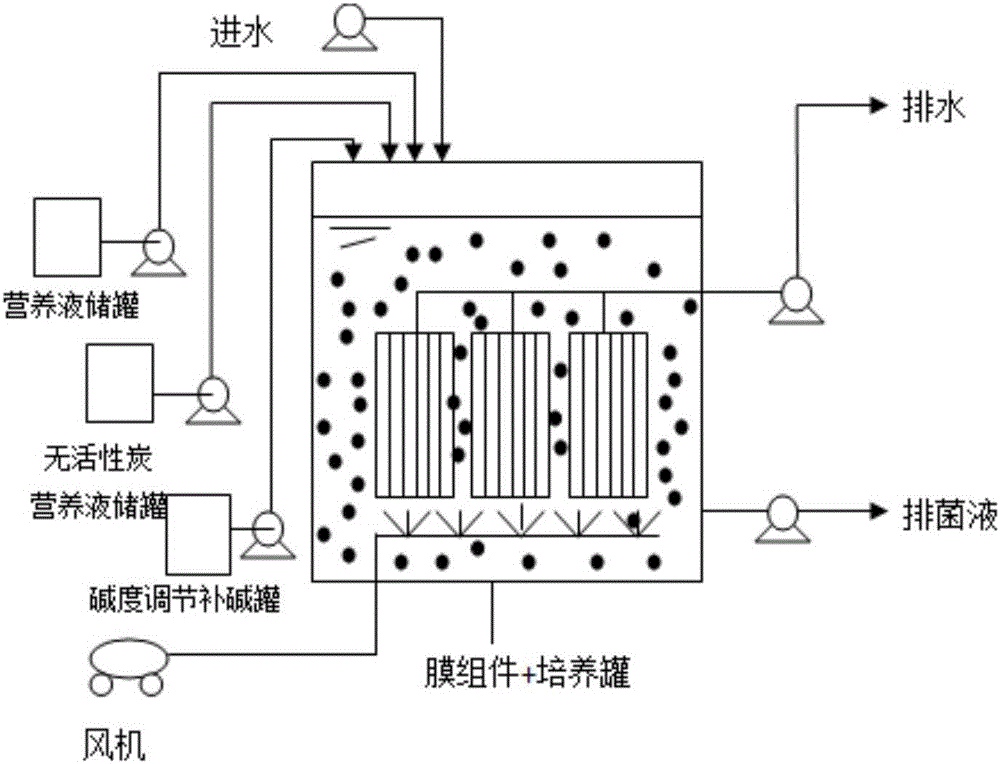

[0044] NB1 cultivation process: press figure 1 Install all the devices and pipelines, and after commissioning, first add tap water to the culture device, when it reaches about 30% of the effective volume, add NM1 medium and nitrifying bacteria NB1, turn on the aeration, and control the pH at 7.50 through NM3 ~7.80, the temperature is maintained at 30°C, and the membrane module does not open at this stage. When the ammonia nitrogen drops to 57mg / L, the membrane filter module is opened, and only the filtrate is discharged, so that the filtrate is continuously discharged at a speed of 55.54L / h (1333L / d). Start the NM-4 feed pump, add NM-4 at a rate of 2.08L / h (50L / d), and start the water pump at the same time to keep the total volume of the culture system at 1000L. When Rn reaches 10mgN / L / h (measure the filtrate ammonia nitrogen in the effluent after every 24h≦57mg / L), use NM-2 instead of NM-4 for feeding, ...

Embodiment 2

[0046] NB2 commercially available nitrifying bacteria culture process

[0047] NB2 cultivation process: press figure 1 Install all the devices and pipelines and complete the debugging.

[0048] First, tap water is added to the cultivation device. When it reaches about 30% of the effective volume, NM1 medium and nitrifying bacteria NB2 are added, aeration is started, and the pH is controlled at 7.50-7.80 by NM3, and the temperature is maintained at 30°C. At this stage, the membrane Component does not turn on. When the ammonia nitrogen drops to 57mg / L, the membrane filter module is opened, and only the filtrate is discharged, so that the filtrate is continuously discharged at a speed of 55.54L / h (1333L / d). Start the NM-4 feed pump, add NM-4 at a rate of 2.08L / h (50L / d), and start the water pump at the same time to keep the total volume of the culture system at 1000L. When Rn reaches 10mgN / L / h (measure the filtrate ammonia nitrogen in the effluent after every 24h≦57mg / L), use ...

Embodiment 3

[0050] NB3 commercially available nitrifying bacteria culture process

[0051] NB3 cultivation process: press figure 1 Install all the devices and pipelines and complete the debugging.

[0052] First, tap water is added to the cultivation device. When it reaches about 30% of the effective volume, NM1 medium and nitrifying bacteria NB3 are added, aeration is turned on, and the pH is controlled at 7.50 to 7.80 by NM3, and the temperature is maintained at 30°C. At this stage, the membrane Component does not turn on. When the ammonia nitrogen drops to 57mg / L, the membrane filter module is opened, and only the filtrate is discharged, so that the filtrate is continuously discharged at a speed of 55.54L / h (1333L / d). Start the NM-4 feed pump, add NM-4 at a rate of 2.08L / h (50L / d), and start the water pump at the same time to keep the total volume of the culture system at 1000L. When Rn reaches 10mgN / L / h (measure the filtrate ammonia nitrogen in the effluent after every 24h≦57mg / L),...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap