Metal die casting shell forming method and intelligent electronic device

A technology for intelligent electronic equipment and casing molding, which is applied in the field of metal die-casting casing molding for intelligent electronic equipment and mobile phones. It can solve the problems of many CNC machining procedures, high machine costs, and many fixtures, and achieve time saving and good product rate. , Fixture cost is low, and the effect of avoiding blackening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Exemplary embodiments according to the present invention will be described in detail below with reference to the accompanying drawings. Those skilled in the art will understand the features and advantages of the present invention from the accompanying drawings and corresponding descriptions.

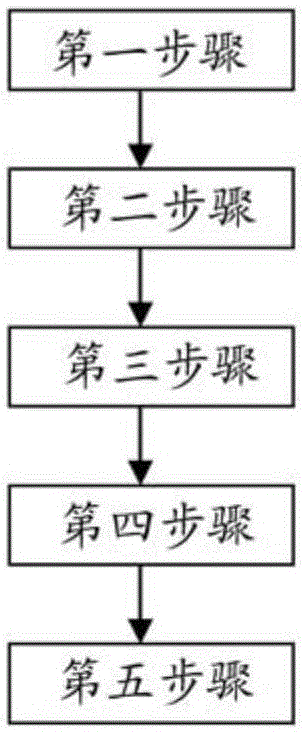

[0039] According to one embodiment of the present invention, figure 1 A flow chart showing a method for forming a metal die-casting shell according to an embodiment of the present invention, wherein the method includes the following steps:

[0040] In the first step:

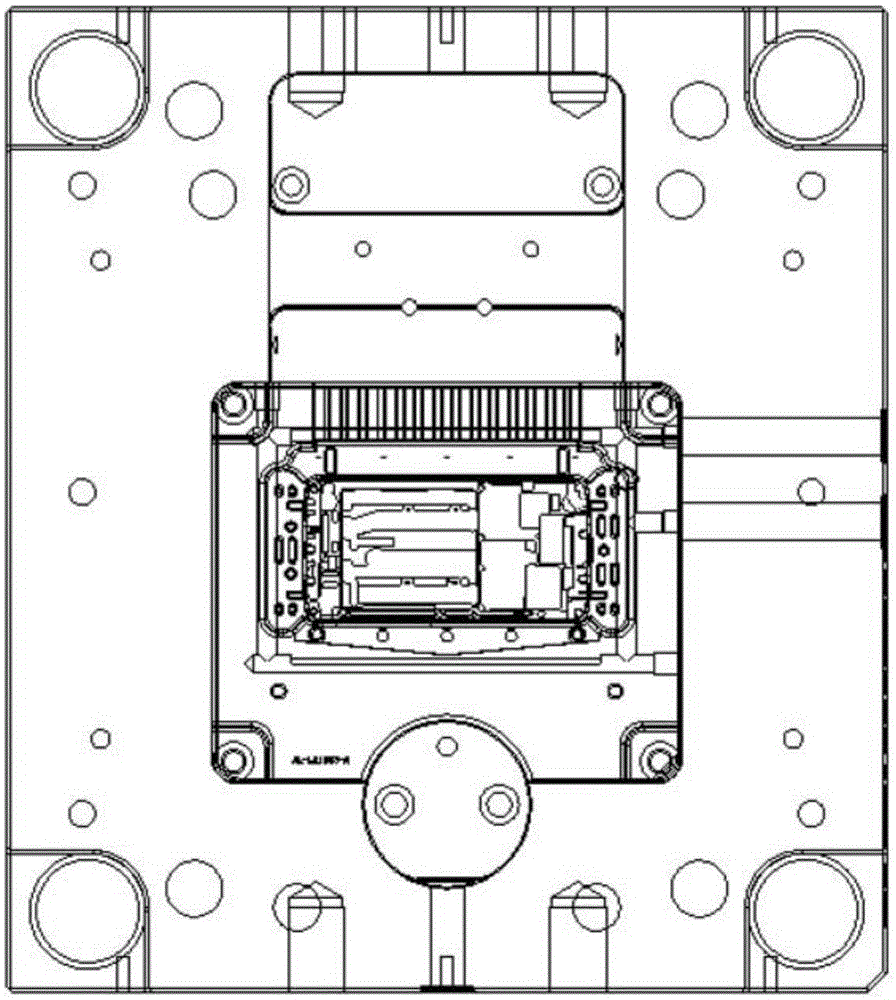

[0041] Transforming metal alloy materials in the solidified state into metal alloy materials in the molten state6 (see Figure 4 ).

[0042] In the second step:

[0043] The metal alloy material in the molten state is injected into the pouring space of the mold by mold casting.

[0044] In the third step:

[0045] The metal alloy material in the molten state is transformed into the metal alloy material in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com