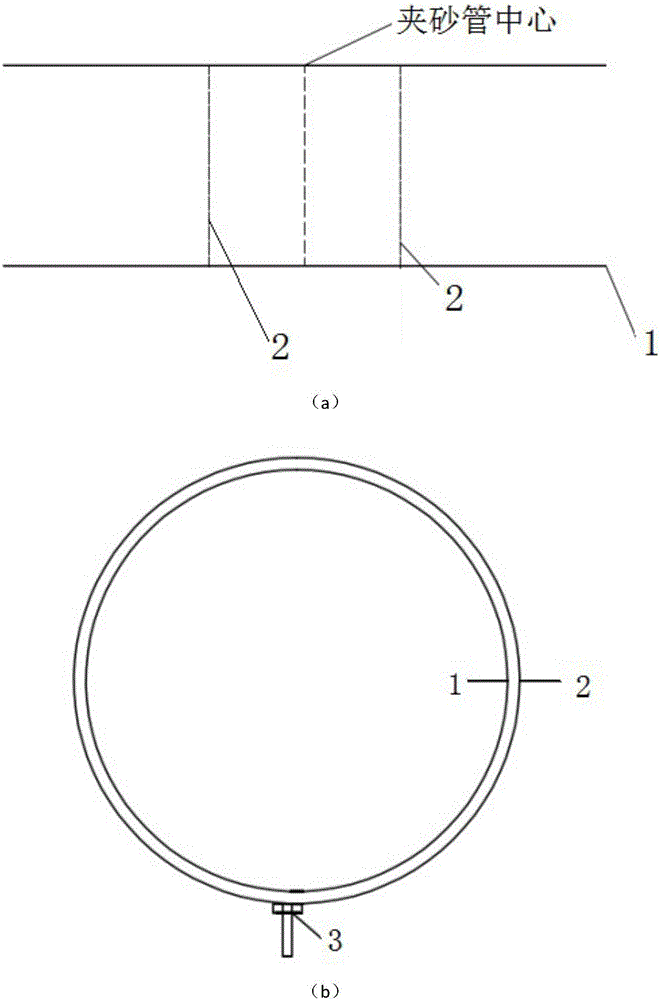

Construction method for fiberglass reinforced plastic mortar pipe culvert of roads

A technology of FRP sand inclusion and construction method, which is applied to the bottom layer of roads, buildings, etc., can solve problems such as poor control, collapsed FRP sand inclusion pipes, and uniformity of force, and achieve the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

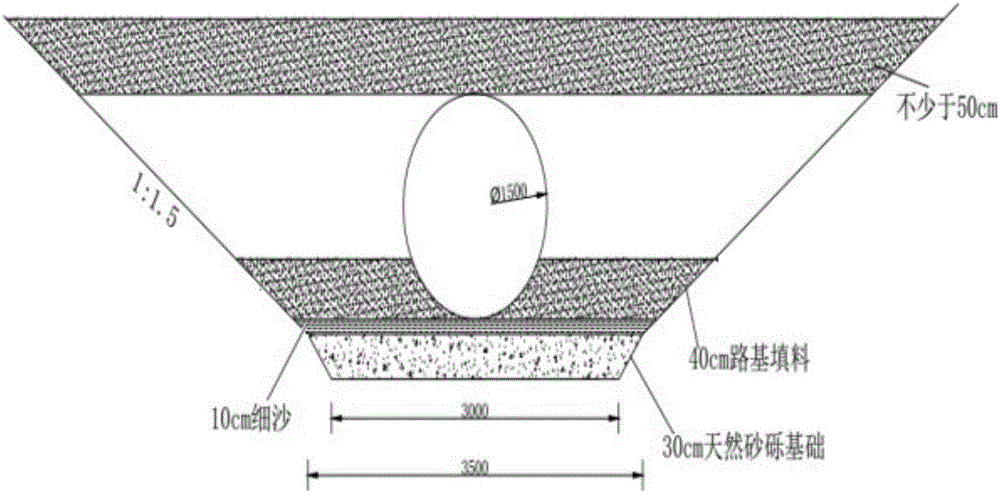

[0046] The diameter of the FRP sand-filled pipe in this embodiment is 1.5m. It is used for the drainage of highway culverts. The soil at the construction site is clay, and the height of the upper end of the FRP sand-filled pipe is less than 1m.

[0047] The specific construction process is:

[0048] The section form of the foundation pit adopts the method of sloping and digging. The two sides of the foundation pit are sloped according to the ratio of slope height: width = 1:1.5. When the diameter is 1.5m, the excavation width of the foundation pit is 3m, and the width of the base replacement with natural gravel is 3.5m (adding 0.5m to the foundation pit excavation width of 3m is 3.5m) (see figure 2 ).

[0049] During base treatment, 30cm natural gravel is used for replacement, and the compaction degree is 98%, forming a 30cm natural gravel foundation. After the base is replaced, 10cm of standard fine sand is firstly spread on the base, and then on the standard fine sand, loe...

Embodiment 2

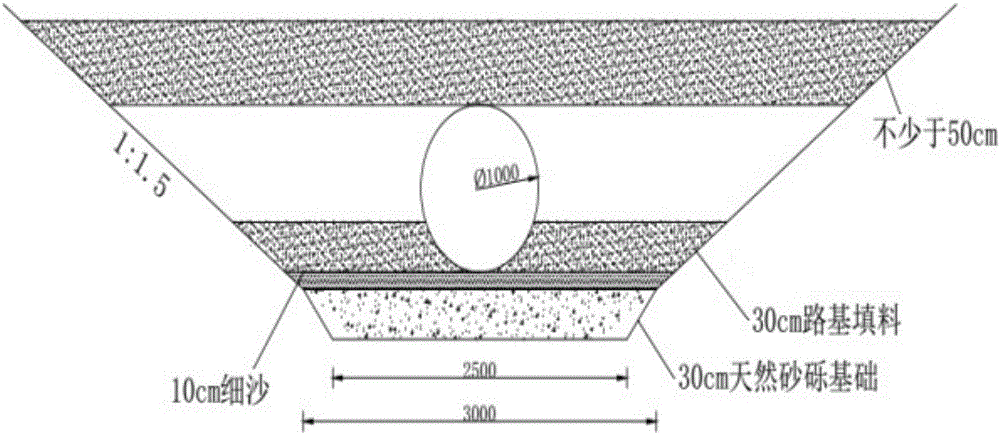

[0055] The diameter of the FRP sand-filled pipe in this embodiment is 1 m. It is used for drainage of highway culverts. The soil at the construction site is clay, and the height of the upper end of the FRP sand pipe is less than 1m.

[0056] The specific construction process is:

[0057] The section form of the foundation pit adopts the method of sloping and digging. The two sides of the foundation pit are sloped according to the ratio of slope height: width = 1:1.5. When the diameter is 1m, the excavation width of the foundation pit is 2.5m, and the width of the base replacement with natural gravel is 3m (adding 0.5m to the foundation pit excavation width of 2.5m is 3m) (see image 3 ).

[0058] During base treatment, 30cm natural gravel is used for replacement, and the compaction degree is 98%, forming a 30cm natural gravel foundation. After the base is replaced, spread about 10cm of standard fine sand on the base, and then fill with loess as subgrade filler on the standa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com