Steel connection water stopping needle

A water-stop needle and conjoined technology, which is used in soil protection, construction, infrastructure engineering, etc., can solve the problems of slurry splashing into the eyes, low safety in use, and oil nozzles falling off, and achieve stable use and use. The effect of good safety, low production cost and high use intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

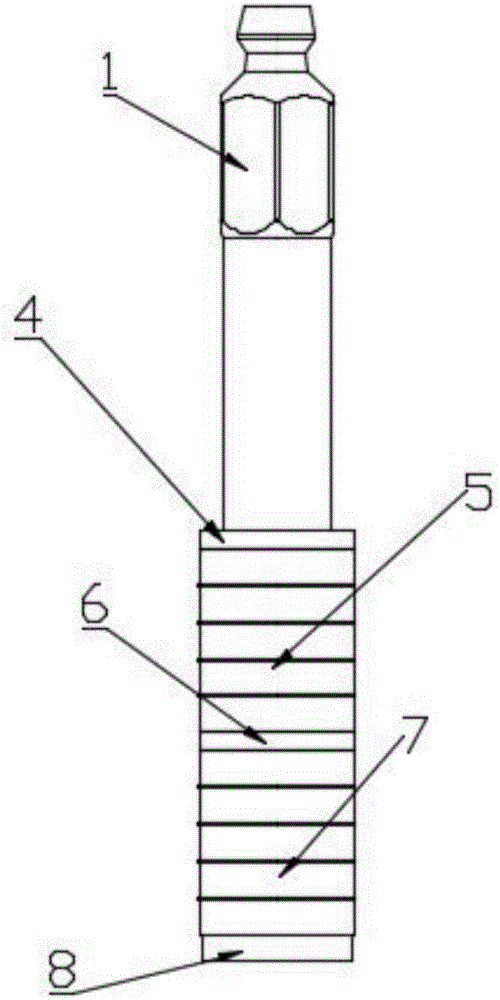

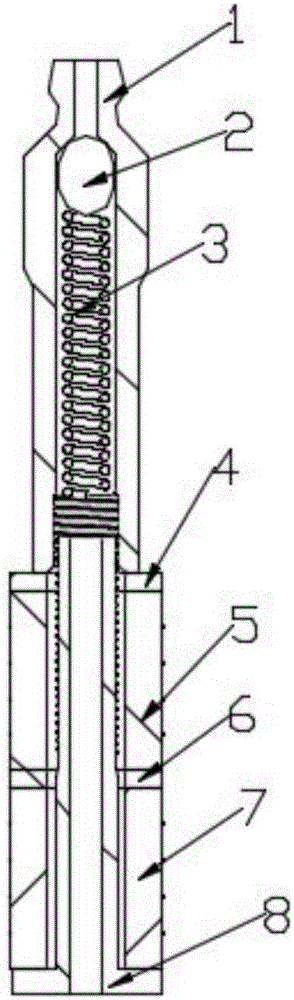

[0015] see Figure 1-2 , a steel one-piece water-stop needle, including a one-piece hexagonal grouting nozzle 1, a rubber ball valve 2, a high-pressure spring 3, a gasket, an expansion ring and a high-strength hollow screw 8, and the one-piece hexagonal grouting nozzle 1 adopts It is made of steel material and adopts integrated molding technology. The gasket includes the first gasket 4 and the second gasket 6. The expansion ring includes the first expansion ring 5 and the second expansion ring 7. The upper ends of the high-strength hollow screws 8 are sleeved in turn. There is a second expansion ring 7, a second gasket 6, a first expansion ring 5 and a first gasket 4, the top of the high-strength hollow screw 8 is connected to the high-pressure spring 3 and the high-pressure spring 3 is located above the first gasket 4, The upper end of the high-p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com