A hybrid temporary plugging volume fracturing method suitable for deep shale gas horizontal wells

A volume fracturing and horizontal well technology, applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

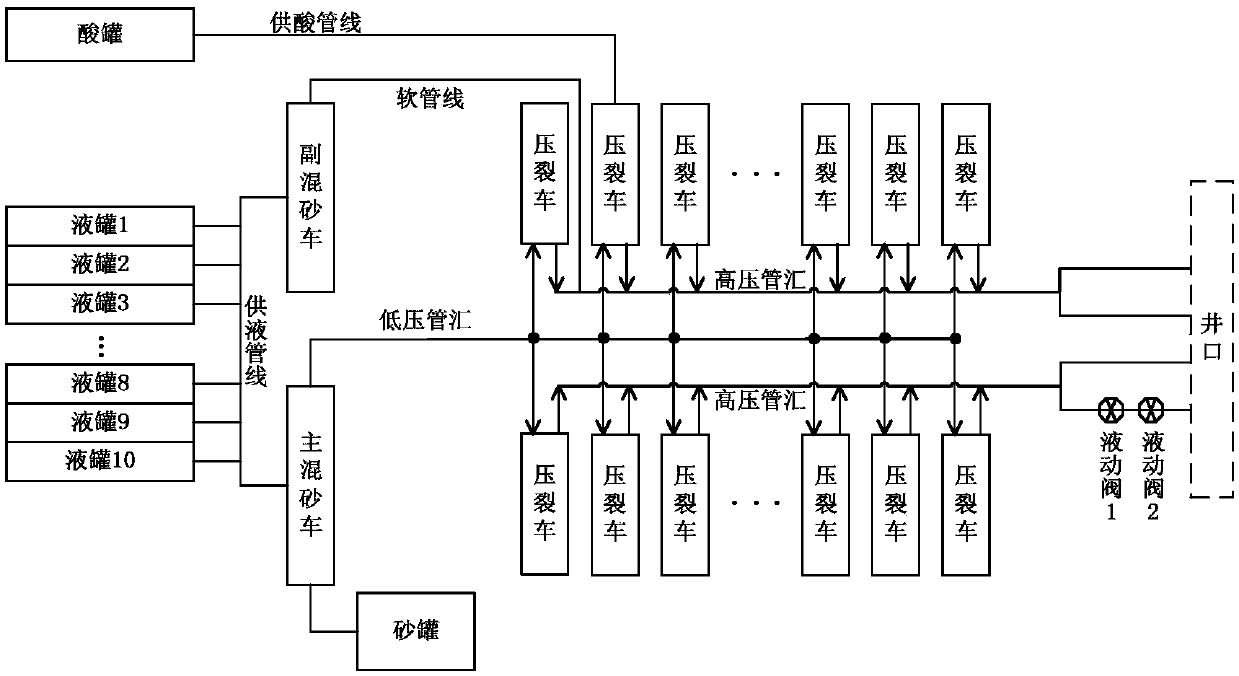

[0123] This embodiment provides a mixed temporary plugging volume fracturing system suitable for deep shale gas horizontal wells, which includes: multiple sets of liquid tanks, main sand mixing trucks, auxiliary sand mixing trucks, sand tanks, and multiple fracturing trucks , hydraulic valve 1 and second hydraulic valve 2;

[0124] Wherein, the multiple groups of liquid tanks (10 groups) are respectively connected with the main sand mixing vehicle and the auxiliary sand mixing vehicle through liquid supply pipelines;

[0125] The sand tank is connected to the mixing tank of the main sand mixing vehicle through pipelines;

[0126] The outlet of the auxiliary sand mixer is connected to the first high-pressure manifold through the hose line and the plug valve, and the first high-pressure manifold is then connected to the wellhead;

[0127] The outlet of the main sand mixing truck is connected to the inlets of multiple fracturing trucks through the low-pressure manifold, and the ...

Embodiment 2

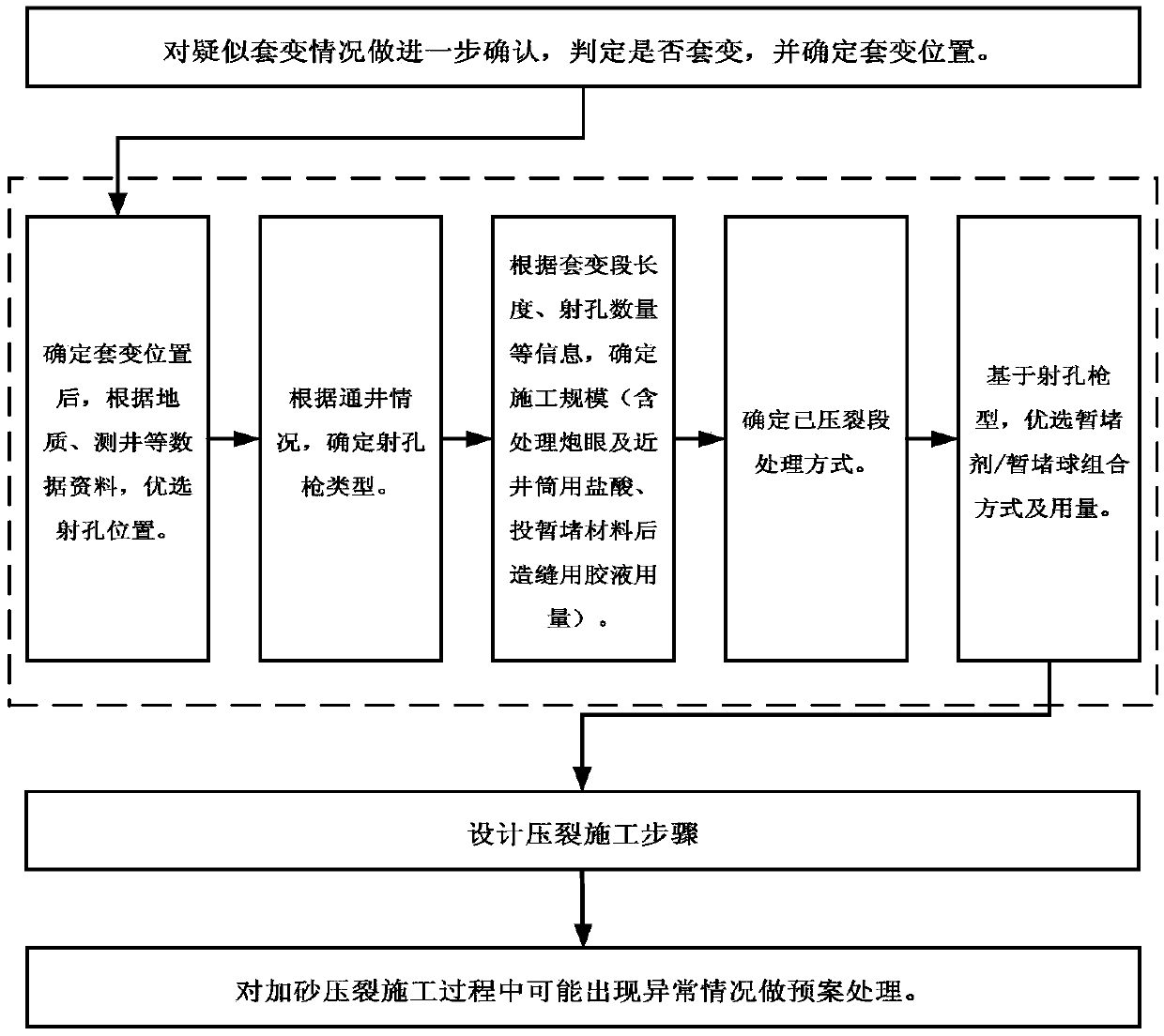

[0130] This example provides a mixed temporary plugging volume fracturing method suitable for deep shale gas horizontal wells, the process flow chart is as follows figure 1 Shown:

[0131] In order to facilitate the adjustment of on-site construction plan, ensure the effect of fracturing operation, intuitively analyze the effect of fracturing operation, and facilitate the analysis of fracturing effect in the later stage, it is necessary to use micro-seismic equipment to monitor the timing and timing of micro-seismic event points generated during fracturing construction in real time. Distribution.

[0132] From figure 2 As can be seen in the figure, the acid tank is a tank used to store the configured hydrochloric acid solution. Usually, before the fracturing operation, hydrochloric acid soaking is carried out in the blast hole of the casing variable well section and the whole wellbore near the wellbore area. The acid liquid is exported from the acid tank, enters the fractur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com