Degradable temporary plugging ball and preparation method thereof

A technology of temporarily blocking balls and degradable materials, applied in the direction of single-component copolyester artificial filaments, etc., can solve the problems of difficult steering, non-degradation of plastic balls, difficulties, etc., and achieve good mechanical strength and elasticity, good compression resistance and Effective degradation and easy control of the reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A degradable temporary blocking ball consists of the following formula (calculated by weight):

[0036] 65 parts of terephthalic acid; 75 parts of ethylene glycol; 15 parts of 1,4-butanedioic acid; 1 part of 1,3-propylene glycol; 3 parts of 1,4-benzenediol; 0.4 parts of ferric chloride; 0.2 parts of formaldehyde, 41 parts of water.

[0037] The preparation method of the degradable temporary blocking ball includes the following contents (produced in batches of 200kg):

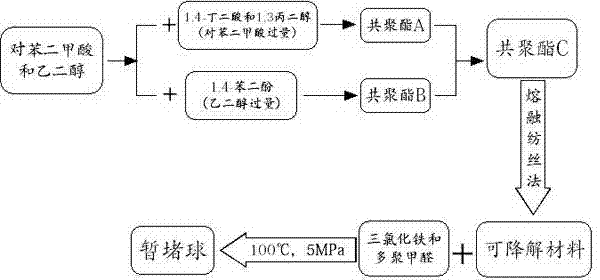

[0038] (1) The preparation steps of the temporary plugging ball are as attached figure 1Shown: Preparation of degradable material: ① 32 parts by weight of terephthalic acid and 38 parts of ethylene glycol are esterified at 250°C, and 15 parts by weight of 1,4-butanediol are added acid, stirring, to obtain an esterification product; adding 1 part by weight of 1,3-propanediol to the esterification product for copolymerization, controlling the final vacuum to 150MPa, and reacting for 3 hours to obt...

Embodiment 2

[0047] A degradable temporary blocking ball consists of the following formula (calculated by weight):

[0048] 64 parts of terephthalic acid; 76 parts of ethylene glycol; 14 parts of 1,4-butanedioic acid; 2 parts of 1,3-propylene glycol; 3 parts of 1,4-benzenediol; 0.4 parts of ferric chloride; 0.2 parts of formaldehyde, 41 parts of water.

[0049] The preparation method of the degradable temporary blocking ball includes the following contents (produced in batches of 200kg):

[0050] The preparation steps of temporary blocking ball are as attached figure 1 Shown:

[0051] 1. Preparation of degradable materials:

[0052] a. In a clean reactor, first add 14kg of clear water, heat up to 30-40°C, add 30kg of terephthalic acid and 40kg of ethylene glycol while stirring, control the addition within 30 minutes, and stir until completely dissolved after adding, Add 14 kg of 1,4-butanedioic acid, raise the temperature to 250° C., stir at a constant temperature, then add 2 k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com