Exhausting and silencing structure for parallel connection hydrodynamic retarder

A hydraulic retarder and retarder technology, applied in the direction of hydraulic resistance brakes, brake components, brake types, etc., can solve the problem of limited exhaust braking effect, etc., and achieve the effect of restoring the noise reduction effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

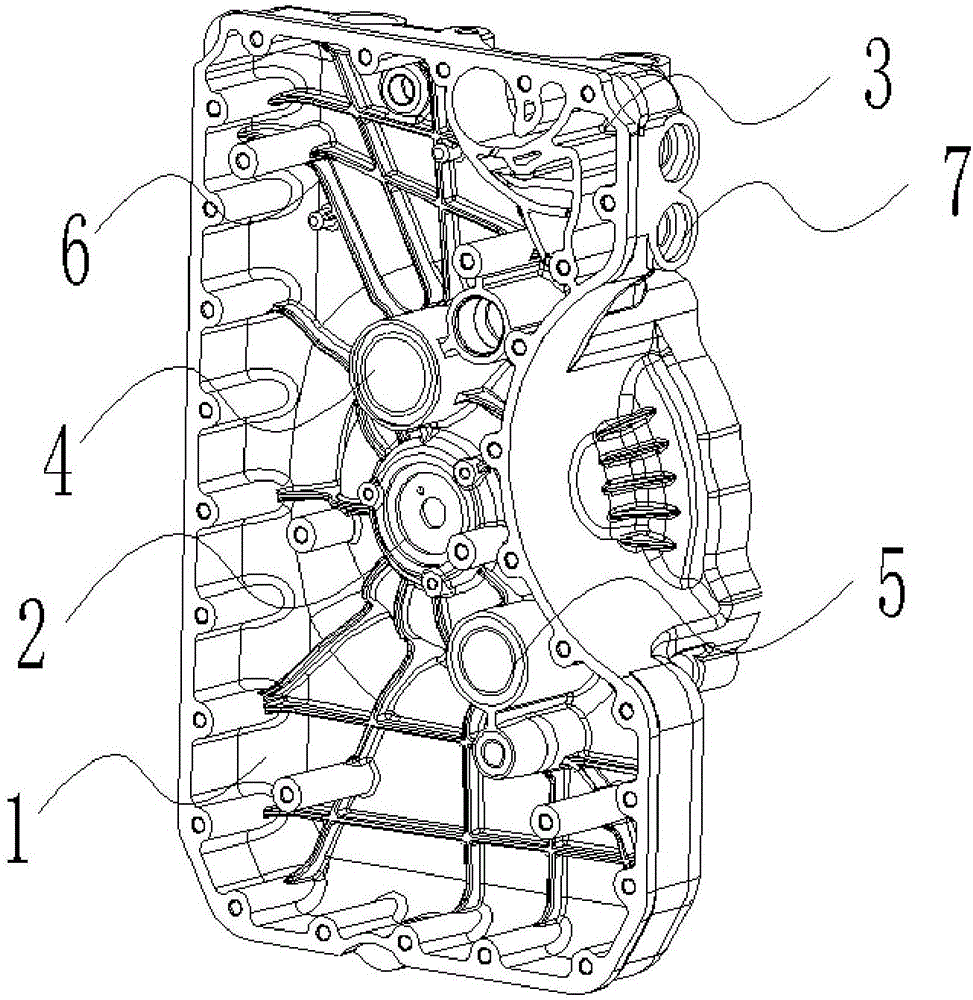

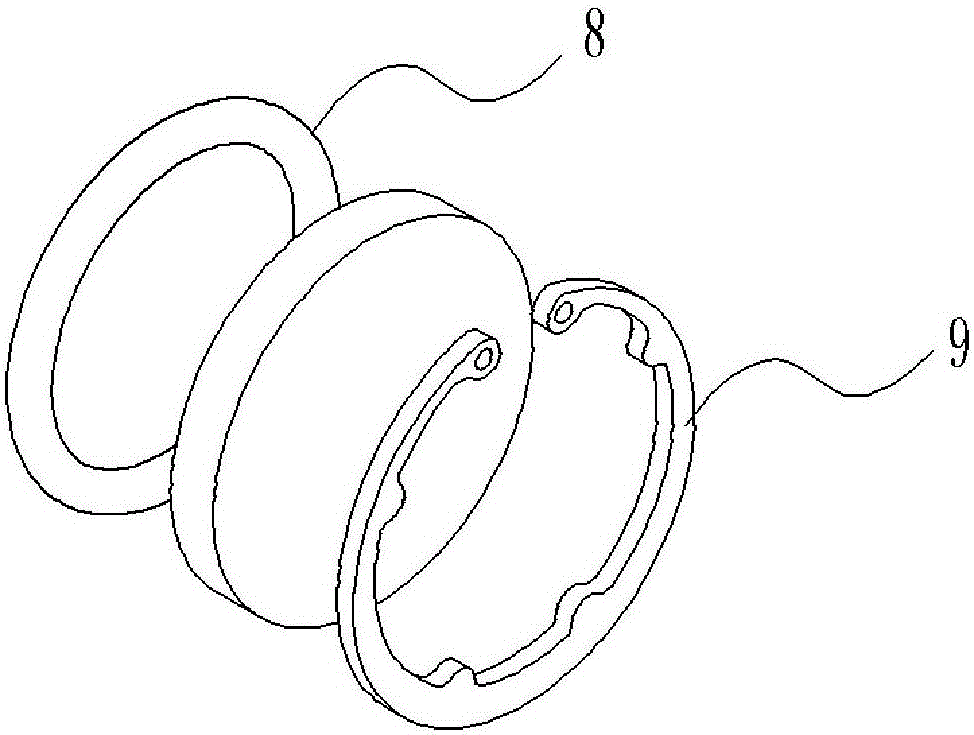

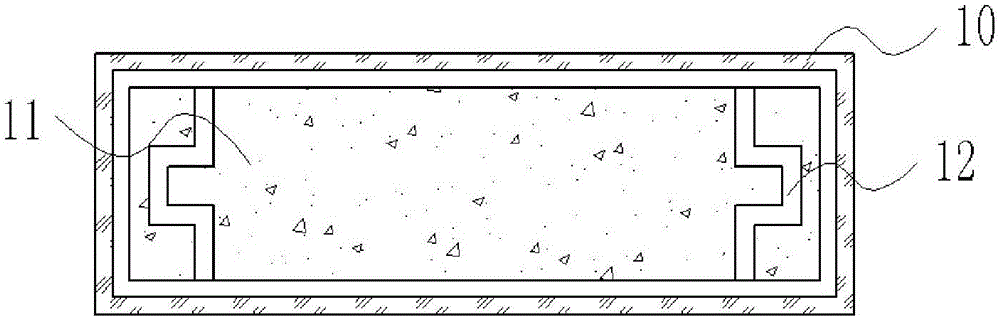

[0020] Such as Figure 1-3 As shown, the present invention discloses an exhaust muffler structure for a parallel hydraulic retarder, including a retarder oil chamber cover and a silencer assembly, and the retarder oil chamber cover is separately provided with an oil collection chamber 1, a working Cavity 2, pressure stabilizing chamber 3, oil inlet passage 4 and oil outlet passage 5. The pressure stabilizing chamber 3 is arranged at one end of the retarder oil chamber cover. The assembly is installed in the air outlet 7.

[0021] The shape of the retarder oil chamber cover adopts a rectangular design. The oil collection chamber 1 is set on the lower half of the retarder oil chamber cover, and the working chamber 2 is set on the surface of the retarder oil chamber cover. It adopts a hemispherical design. Staggered ribs 6, the oil inlet passage 4 is arranged on the side of the working chamber 2 and runs through the retarder oil chamber cover, and the oil outlet passage 5 is arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com