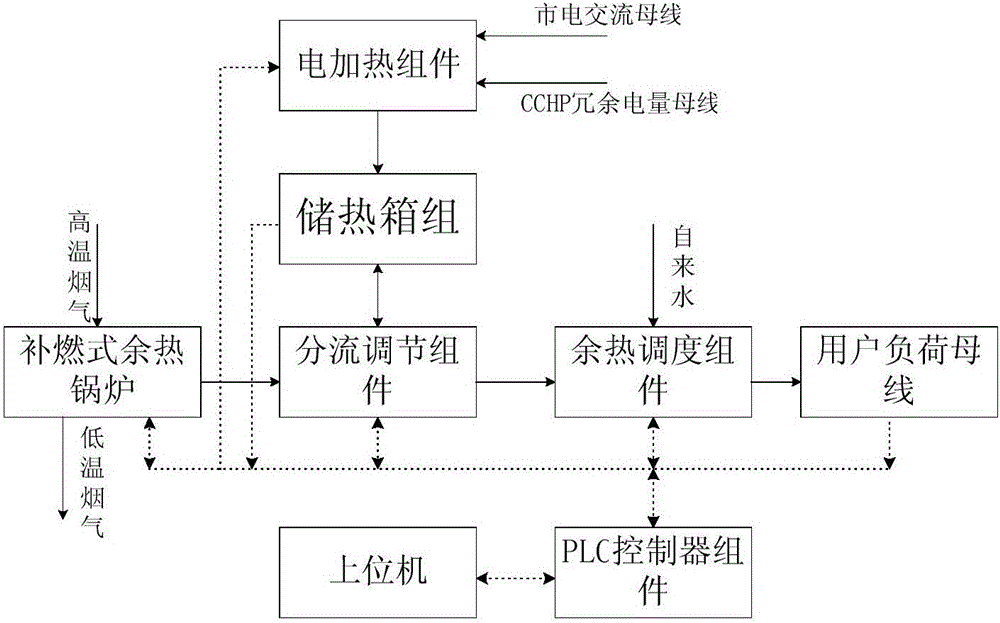

Heat storage adjusting system based on combined cooling heating and power and adjustment method thereof

A technology of combined cooling, heating and power generation and adjustment system, which is applied in the field of heat exchange management, and can solve the problems of single energy adjustment form and unsatisfactory heat storage effect of heat storage devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

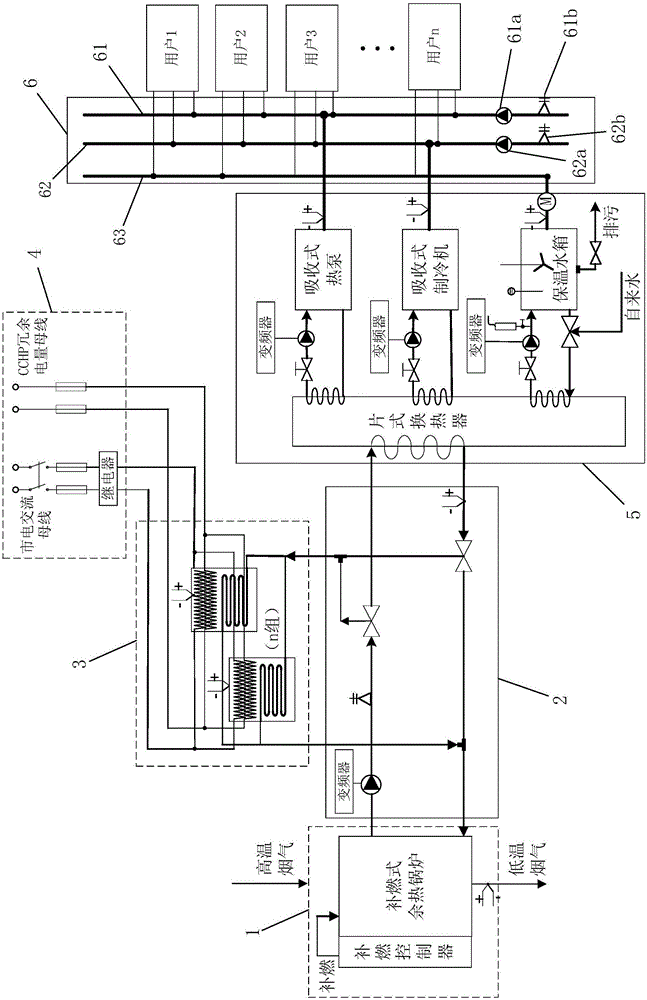

[0121] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0122] This embodiment can be applied to a heat storage and adjustment system of a micro cogeneration system of cooling, heating and power in a certain community.

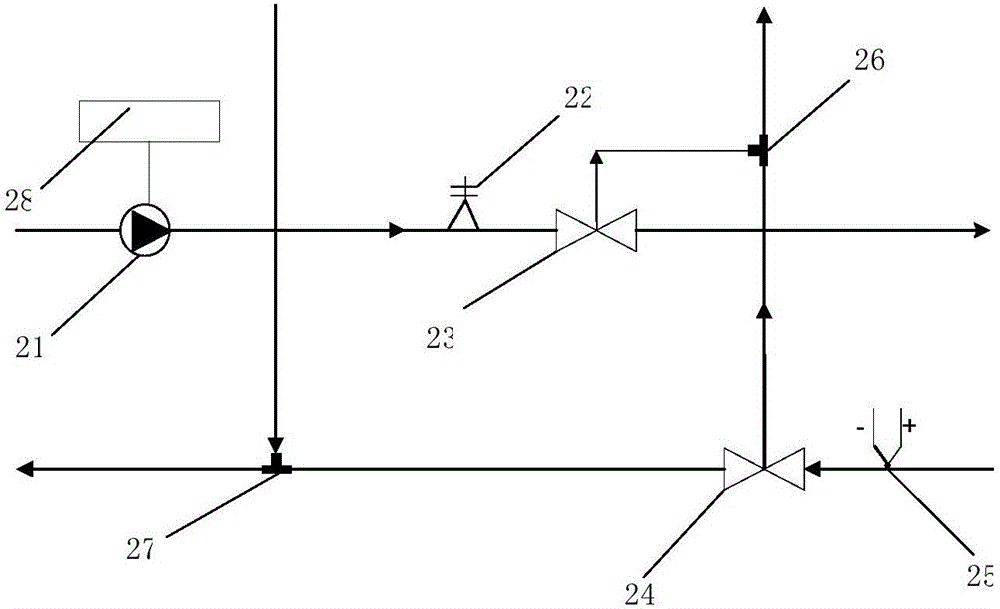

[0123] In this embodiment, the model selected by the PLC in the PLC controller component is Siemens 315-2DP, the supplementary combustion waste heat boiler 1 adopts a flue gas type supplementary combustion waste heat boiler produced by Refeng Boiler Co., Ltd., and the absorption refrigerator 54 adopts The LG hot water lithium bromide absorption refrigerator of Pengfei Refrigeration Equipment Co., Ltd., the absorption heat pump 52 adopts the RBIIW-60 / 55-15 / 21 absorption heat pump of Qianjia New Energy Co., Ltd., and the flow regulating valve adopts ZDLQ-DN15 flow rate Regulating valve, sheet heat exchanger 56 choose Binglida plate heat exchanger, circulating water pump choo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com