An online detection system for train wheel set size and runout tolerance

A runout tolerance and detection system technology, applied in the direction of measuring devices, mechanical measuring devices, instruments, etc., can solve the problems of large detection errors in measurement results, achieve high repeat positioning accuracy, improve repeat positioning accuracy, and meet the effect of production beats

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

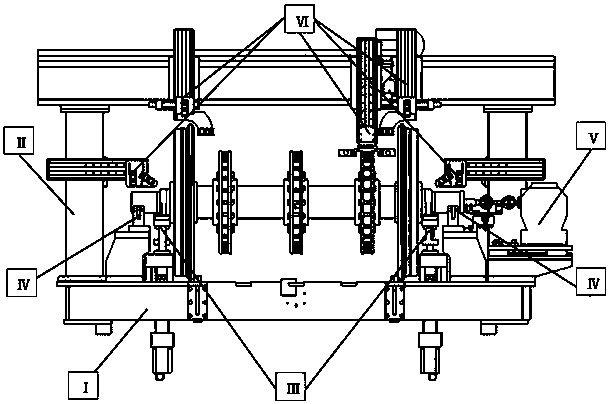

[0043] Below in conjunction with accompanying drawing and embodiment, the present invention is described in further detail: train wheelset size and run-out tolerance on-line detection system, mechanical system such as figure 1 As shown, it is composed of base I, gantry frame II, wheel set conveying device III, wheel set positioning reference support device IV, wheel set rotation drive device V, and high-precision movement detection device VI; Gantry frame II, wheel set conveying device III, wheel set positioning datum support device IV, wheel set rotation driving device V; high precision movement detection device VI is installed on the gantry frame II.

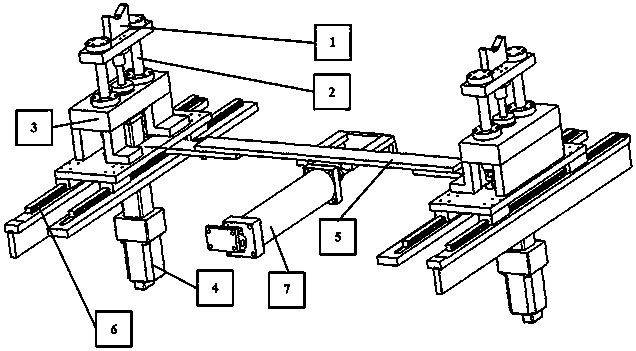

[0044] Such as figure 2 The wheel set conveying device III shown is composed of a V-shaped support seat 1, a linear bearing 2, a bearing support frame 3, an electric push cylinder 4, a moving frame 5, a linear guide rail 6 and a cylinder 7, and the linear guide rail 6 is symmetrically installed on the On the base I, it is re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com