Assembling method of water temperature sensor

A technology of a water temperature sensor and an assembling method, which is applied in the field of sensor testing, can solve the problem of no water temperature sensor assembling method, etc., and achieve the effect of simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

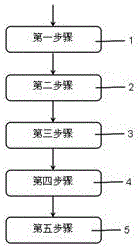

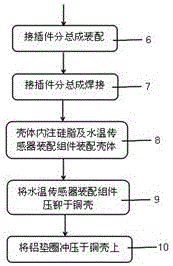

[0029] This embodiment: as figure 1 , 2 Shown, a kind of water temperature sensor assembly method comprises:

[0030] First step 1: Connector sub-assembly assembly 6 .

[0031] Second step 2: Welding 7 of the connector sub-assembly.

[0032] The third step 3: Inject silicone grease into the housing and assemble the water temperature sensor assembly assembly 8: Obtain the water temperature sensor assembly assembly and socket it on the corresponding column of the corresponding mold tooling, and the detection equipment of the water temperature sensor is socketed on the corresponding mold tooling If the water temperature sensor assembly assembly on the corresponding column is qualified, inject silicone grease into the copper shell and take it off and buckle the copper shell upside down on the tooling column. After the copper shell is buckled upside down, take off the tooling and flip it out After filling the water temperature sensor with silicone grease, put the connector sub-a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com