A method for testing the sealing performance of soft double-layer bottles

A technology of sealing performance and detection method, which is applied in the direction of using liquid/vacuum degree for liquid tightness measurement, and by measuring the acceleration and deceleration rate of fluid, etc. Guaranteed accuracy and reliability, increased pressure value, and reasonable test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

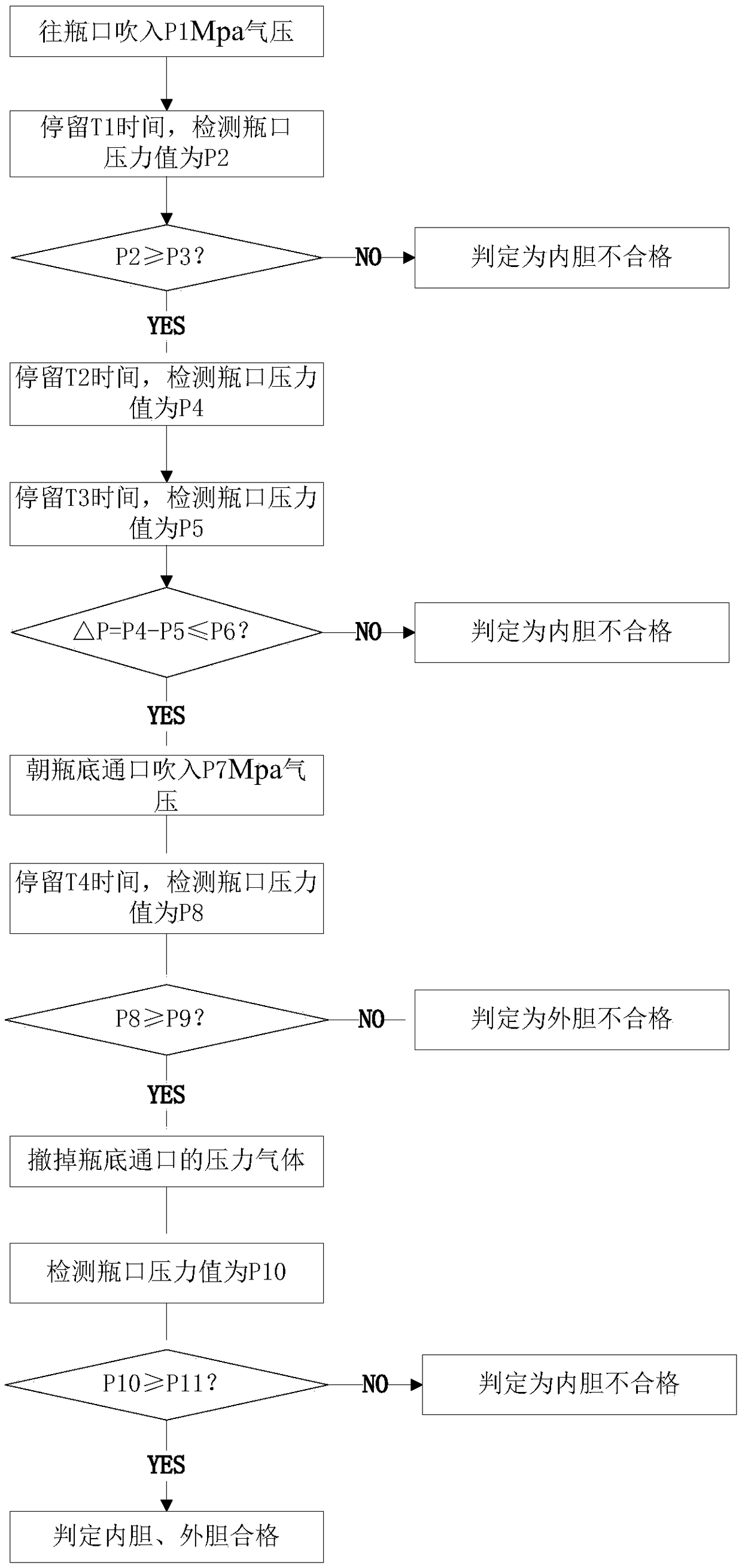

[0035] Please refer to figure 1 , the present embodiment is a method for detecting the sealing performance of a soft double-layer bottle, which is used to detect the sealing performance of a soft double-layer bottle. The soft double-layer bottle includes an inner container, an outer container that wraps the inner container and A bottle mouth communicated with the inner tank. A middle space is formed between the inner liner and the outer liner, and the bottom of the soft double-layer bottle is provided with a port communicating with the middle space.

[0036] The present embodiment is a soft double-layer bottle sealing performance detection method, which includes the following steps,

[0037] 1) Continuously blow 1Mpa air pressure towards the bottle mouth;

[0038] 2) After staying for 0.5S, the measured bottle mouth pressure value is P2;

[0039] 3) Determine whether P2 reaches the reference value of 0.95Mpa, if so, proceed to the next step, otherwise, determine that the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com