Water resistance test bench for mobile circulating water locomotive and its application method

A technology of water resistance test and circulating water, which is applied in the direction of railway vehicle testing, etc., can solve the problems affecting the detection accuracy, left and right shaking, etc., and achieve the effect of reducing short-circuit accidents, improving utilization rate, and improving the detection accuracy of locomotive parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

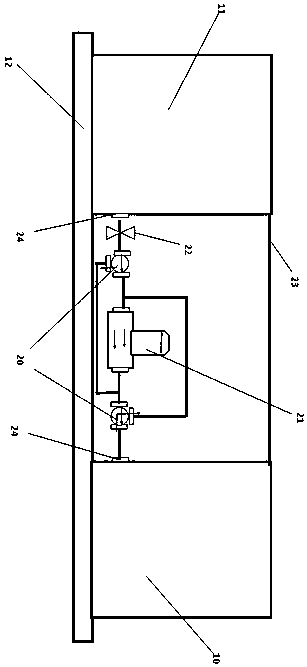

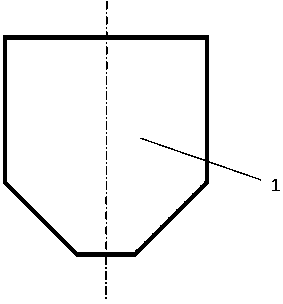

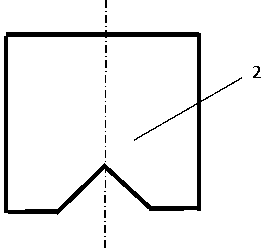

[0033] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the method for using the water resistance test bench for a mobile circulating water locomotive provided by the present invention includes a water resistance box 10 , a pool box 11 and a transport base 12 . The casings of the water resistance box and the pool box are all made of steel, and are welded on the transport base at the bottom of the box body, wherein, the bottom position in the water resistance box is provided with a lower support channel steel 13 and a lower fixed channel steel 14. Insulation terminals are provided between the lower support channel steel and the lower fixed channel steel, and the lower support channel steel is set as a three-layer structure. The positive plate and the negative plate are distributed alternately in the water resistance box. The positive plate 1 is a convex structure at the bottom, and the negative plate 2 is a concave structure at the bottom. An insula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com