Initiative detection device for oil pollution degree

A technology for oil pollution degree and active detection, which is applied in the direction of measuring devices, preparation of test samples, analysis of suspensions and porous materials, etc., and can solve problems such as high cost, difficult operation, and complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

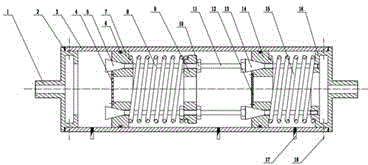

[0018] The specific working process of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0019] The present invention is an active detection device for oil pollution degree, which mainly consists of an oil inlet cover 1, a circular shell 3, a filter piston 7 for 15um particles, a filter piston 14 for 5um particles, a return spring 8, 15, and a spoiler 9. Throttle valve rod 11, oil outlet cover 16 and pressure sensor 17 are composed; the present invention is connected in parallel with the oil system to be detected, and the oil to be detected with a certain pressure enters the oil inlet end cover from the oil inlet end cover 1 1. In the closed cavity formed by the circular shell 3 and the oil outlet cover 16, the filter piston 7 with 15um particles first comes into contact with it; due to the action of the return spring 8 between the filter piston 7 with 15um particles and the spoiler 9, The two symmetrically distributed thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com