On-line detection method for internal shriveling defects of walnut

A detection method, walnut technology, applied in special scales, measuring devices, testing plant materials, etc., can solve the problems of low water content, large amount of information data, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

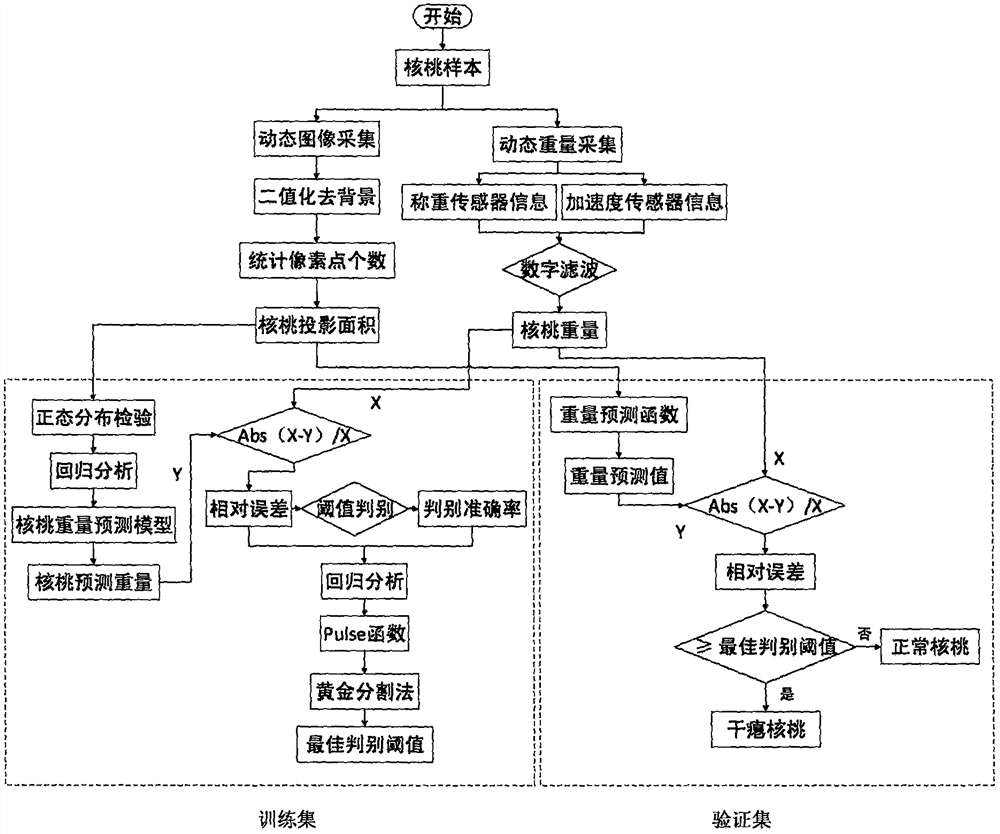

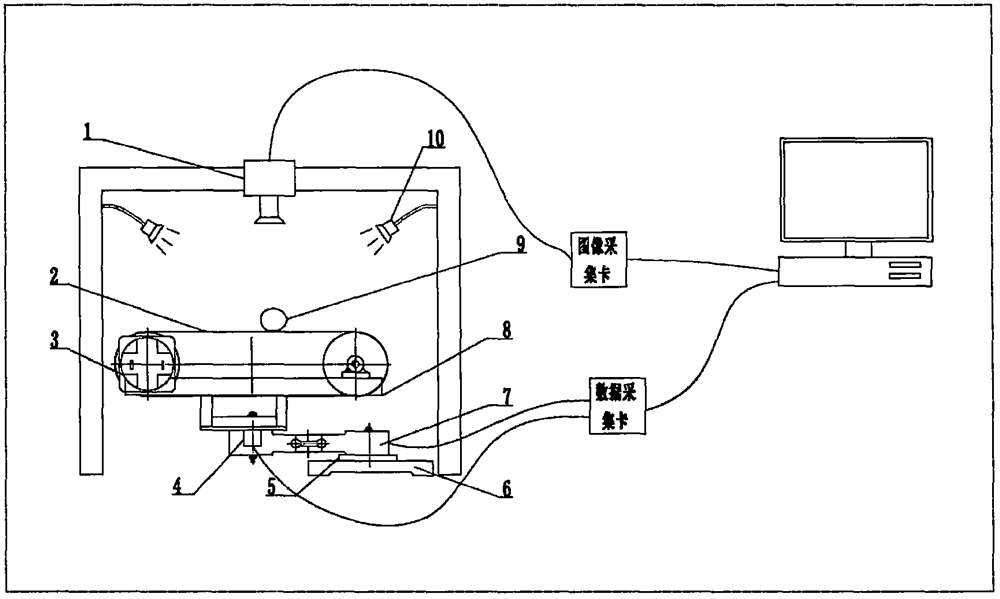

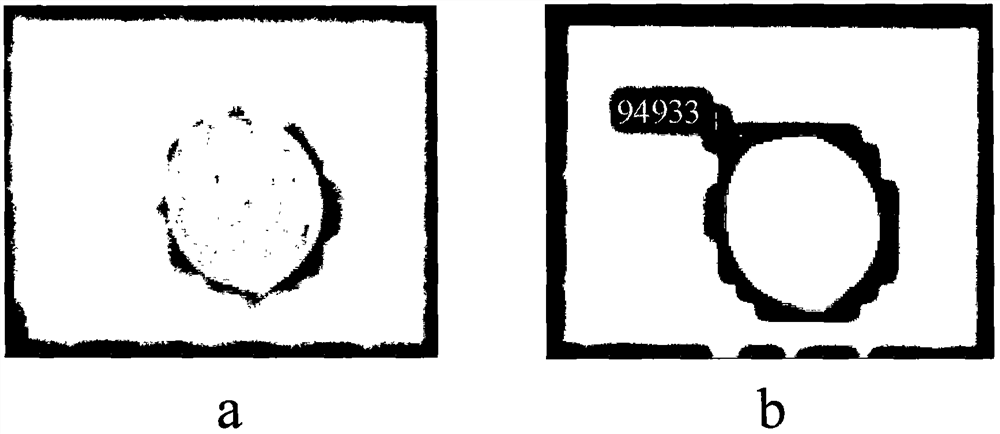

[0023] Example: figure 1 Shown is the flow chart of the realization of the online detection method for walnut internal shriveling defects. First of all, the walnut sample is placed on the synchronous conveyor belt 2, and the clear image is obtained by the industrial CCD camera 1, and it is binarized to obtain its projected area, and the load cell 5 and the digital acceleration sensor 6 are used simultaneously The weight information of the walnut under the dynamic conditions is obtained in a combined way; then the walnut weight prediction model obtained by the regression analysis of the projected area and weight of the walnut is used to calculate the predicted weight of the walnut, and calculate the relationship between it and the real quality of the walnut. Relative error, using the relative error as the discrimination threshold to judge whether the detected walnut is shriveled walnut, and crack the shell to verify the discrimination accuracy; then perform regression analysis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com