Foldable sample loading arm for sample loading devices

A sampling device, sampling arm technology, applied in the direction of analysis of materials, instruments, etc., can solve the problems that affect the efficiency of sampling, sampling and cleaning, non-professional misoperation, lost steps of rotating motors, etc., to reduce the risk of lost steps , avoid wear and aging, improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

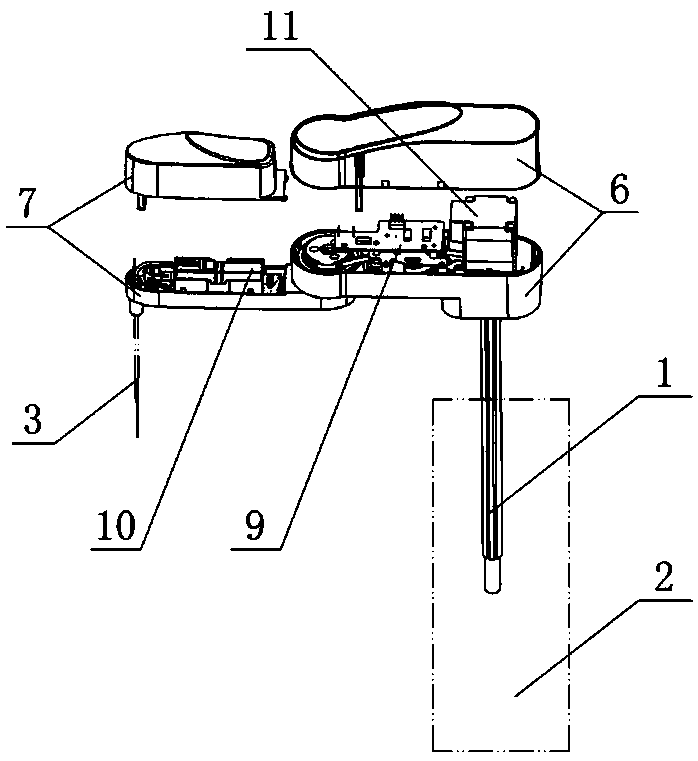

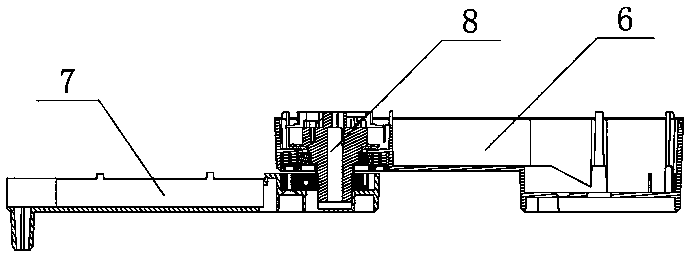

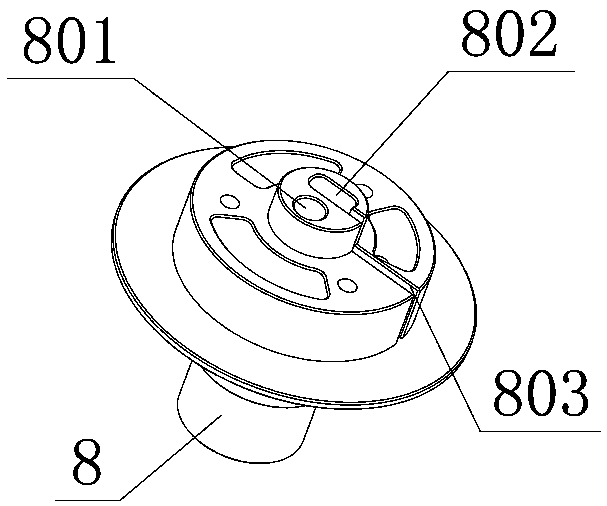

[0017] Such as figure 1 As shown, the foldable sample loading arm suitable for the sample loading device of the present invention includes a sample loading arm body, one end of the sample loading arm body is connected to the sample loading base 2 through the rotating lifting shaft 1, and the other end is connected to the sample loading needle 3 connected. Such as figure 1 , 2 , 4, the sample loading arm body includes the main arm 6 and the auxiliary arm 7, the main arm 6 is connected with the rotating lifting shaft 1, the auxiliary arm 7 is connected with the sampling needle 3, and the intersection of the main arm 6 and the auxiliary arm 7 passes through the rotating shaft 8 connected. In this example, if figure 2 As shown, the main arm 6 is located above the auxiliary arm 7 , and the rotating shaft 8 passes through the intersection of the main arm 6 and the auxiliary arm 7 . Specifically, the upper end of the rotating shaft 8 is sleeved with a bearing, and the bearing f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com