New transformer and box change

A transformer and box-changing technology, which is applied in the field of voltage transformers, can solve the problems of limited spacing between porcelain bottles and reduce the insulation effect, and achieve the effect of short insulation distance, improved insulation effect, and reduced the probability of safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

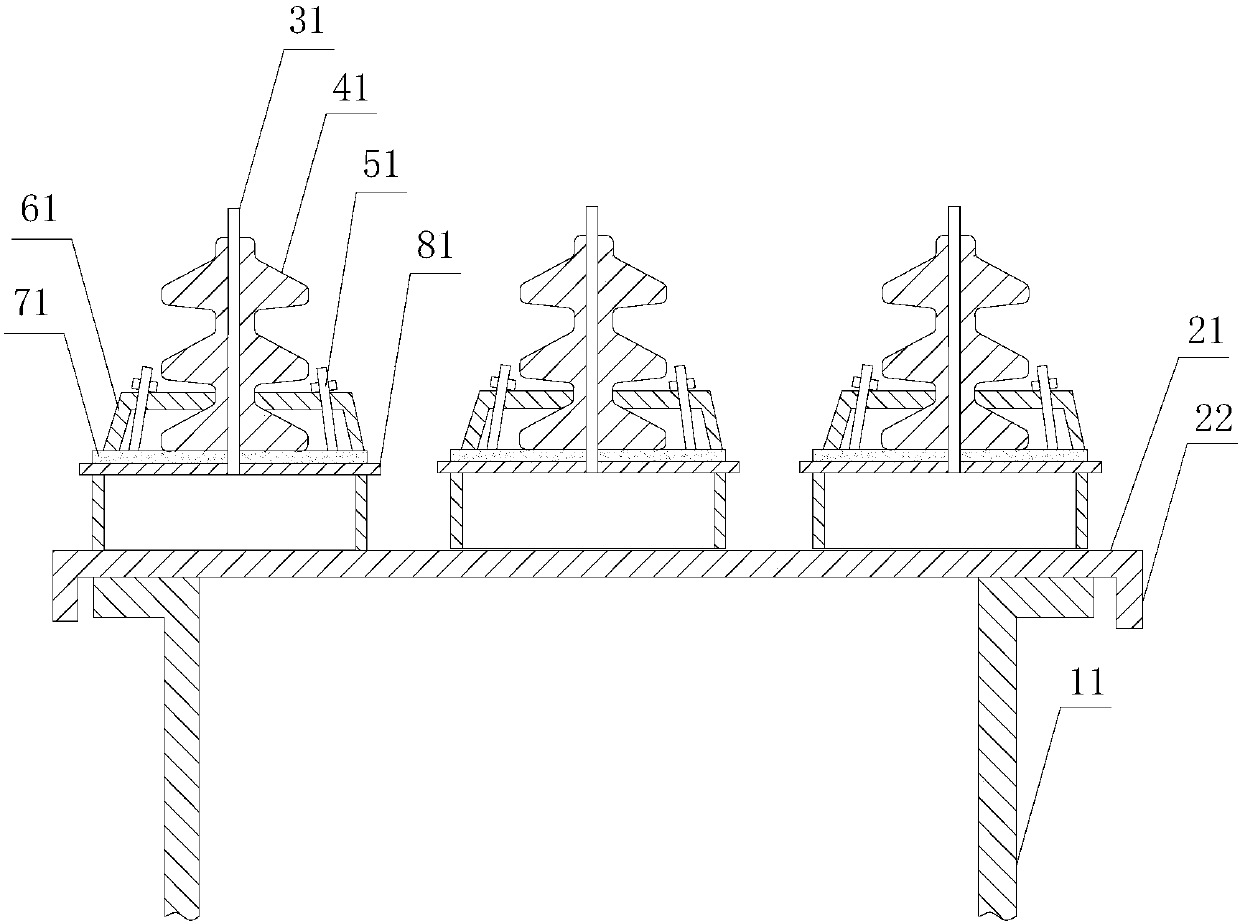

[0054] figure 1 Schematically provides the basic structural diagram of the novel transformer of the embodiment of the present invention, as figure 1 As shown, the new transformer includes:

[0055] a top cover, the top cover comprising:

[0056] a horizontal portion 21, the horizontal portion is fixed on the transformer housing 11 through a second connecting piece;

[0057] The bending part 22, the bending part is arranged at the end of the horizontal part, bent downward; adjacent bending parts are connected together;

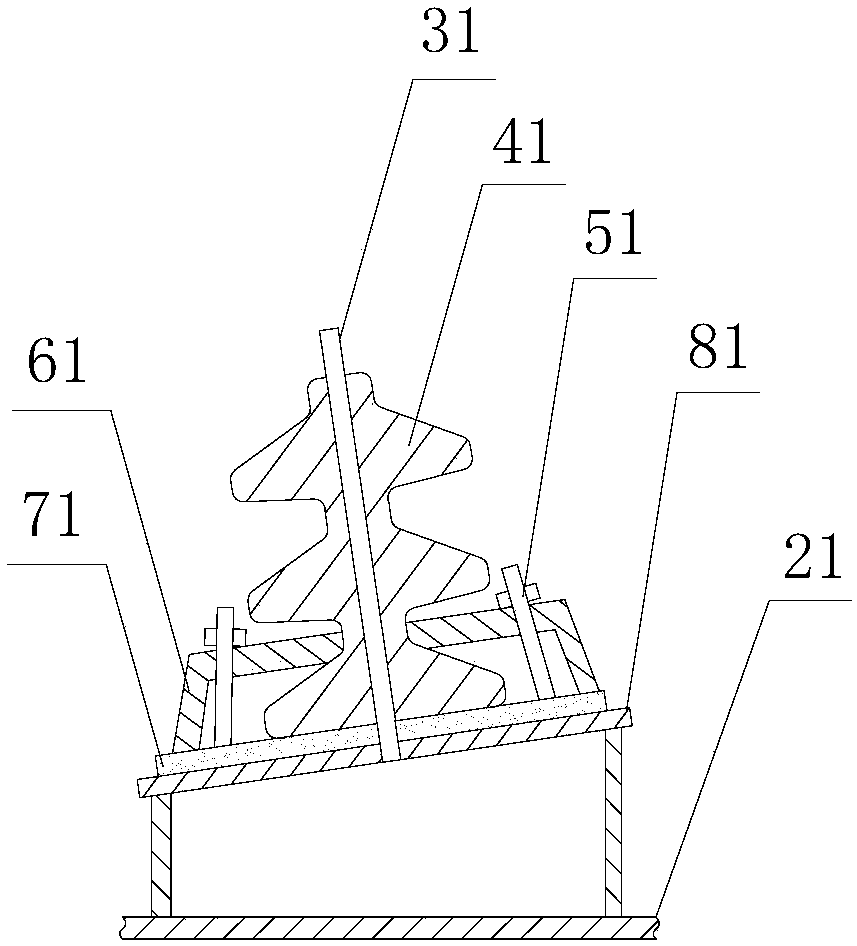

[0058] raised seat 81, such as figure 2 As shown, the raised seat is fixed on the horizontal part 21 of the top cover, the central axis of the raised seat is perpendicular to the top cover, the angle between the end and the central axis is an acute angle, and the adjacent end The angle between the normal lines of the parts is an acute angle;

[0059] Insulating porcelain bottle 41, the high-voltage access end 31 of the transformer passes through the throu...

Embodiment 2

[0064] The novel transformer of the embodiment of the present invention is different from Embodiment 1 in that:

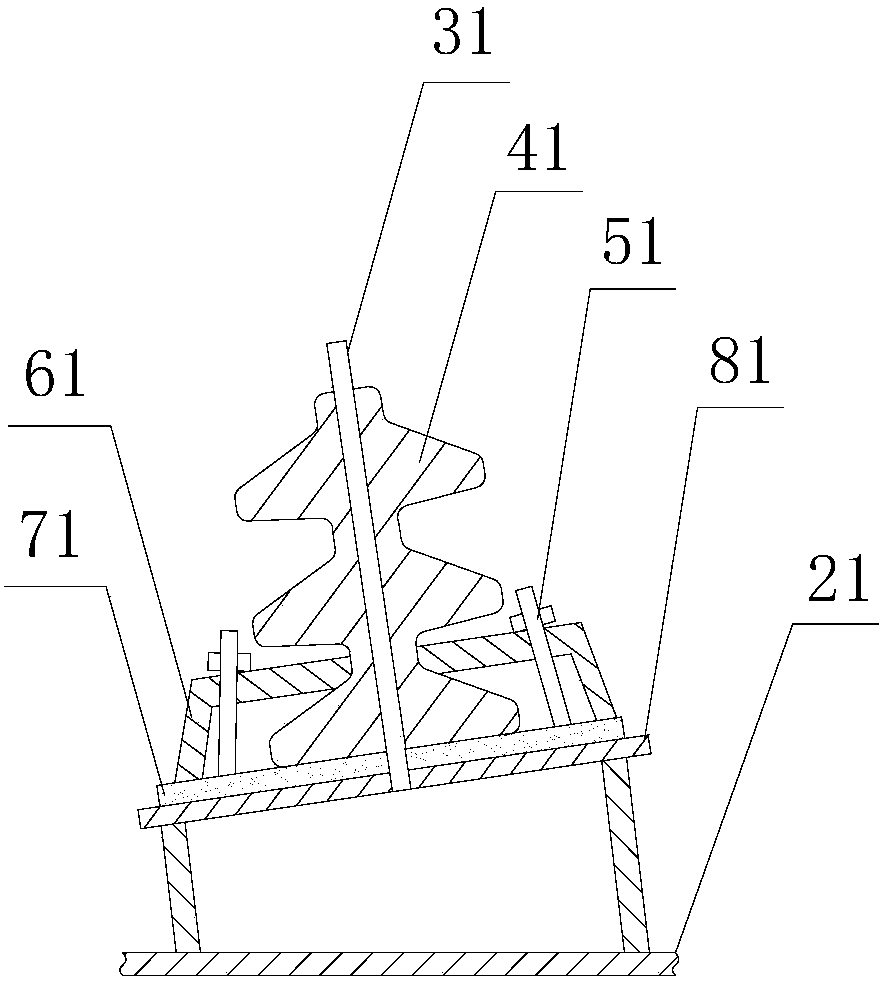

[0065]like image 3 As shown, the included angle between the central axis of the raised seat 81 and the horizontal portion 21 of the top cover is an acute angle, the raised seat 81 is inclined toward the same side of the top cover, and the included angle between the end and the central axis is Right angle, the angle between the normal lines of adjacent ends is an acute angle; the insulating porcelain bottle 41 is fixed on the end, inclined towards the same side of the horizontal part of the top cover, and the included angle between adjacent insulating porcelain bottles 41 is an acute angle.

Embodiment 3

[0067] In the box-type substation according to the embodiment of the present invention, the box-type substation includes:

[0068] a box body, the box body includes a first chamber, a second chamber and a third chamber isolated from each other;

[0069] A high-voltage switchgear, the high-voltage switchgear is arranged in the first chamber, and the output high-voltage power is sent to the transformer for step-down (or the boosted high-voltage power output by the transformer is sent to the high-voltage switchgear); as Figure 4-5 As shown, the high-voltage switchgear includes:

[0070] The switchgear and the operation panel 211 are all existing technologies in the art, and will not be described in detail here.

[0071] The closed container 251 is welded as a thick steel plate, the closed container is arranged on the rear side of the operation panel, and the inside is filled with insulating gas, such as sulfur hexafluoride, and the switchgear is arranged in the closed container...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com