Remote intelligent inspection system for transformer substations and implementation method of inspection system

A technology of intelligent inspection and substation, applied in the direction of electrical components, circuit devices, etc., can solve the problems that cannot completely replace manual inspection, achieve the effects of shortening the response time of accident handling, improving the operation and maintenance mode, and ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] A substation remote intelligent inspection system proposed by the present invention and its implementation method are further described below in conjunction with the accompanying drawings and specific embodiments.

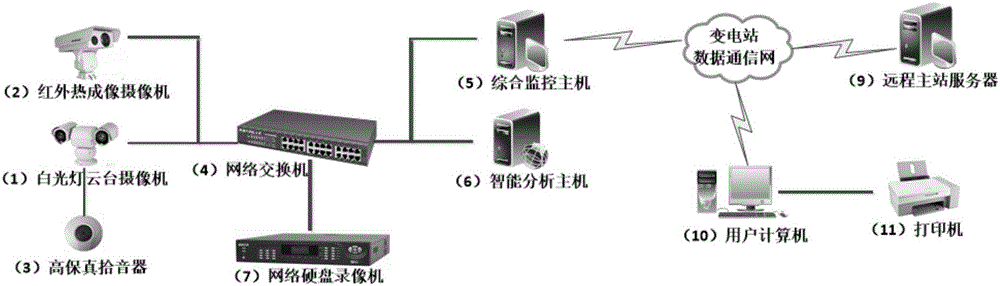

[0029] A substation remote intelligent inspection system proposed by the present invention, its structure diagram is as follows figure 1 As shown, the system consists of a white light pan-tilt camera (1), an infrared thermal imaging camera (2), a high-fidelity pickup (3), a network switch (4), a comprehensive monitoring host (5), an intelligent analysis host (6), The network hard disk video recorder (7), the substation data communication network (8), the remote main station server (9), the user computer (10) and the printer (11). The white light pan-tilt camera (1), the infrared thermal imaging camera (2), the integrated monitoring host (5), the intelligent analysis host (6) and the network hard disk video recorder (7) are respectively connected to the netwo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com