Burr preventive forming method for splayed holes of PCB (printed circuit boards)

A technology of PCB board and forming method, which is applied in the field of anti-burr forming of the eight-character hole of PCB board, can solve the problems of poor burr in the hole, lower product quality, waste of raw materials, etc., and achieve the effect of simple structure, improved quality, and saved raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

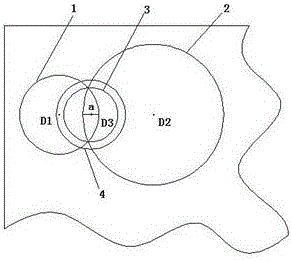

[0022] An embodiment provided by the present invention is: a method for forming a burr-proof hole on a PCB board, the forming method comprising the following steps:

[0023] S1. Determine the center D1 and diameter d1 of the eight-character hole 1 and the center D2 and diameter d2 of the hole 2 on the PCB according to the design requirements;

[0024] S2. Set the line segment at the widest point of the intersection of hole 1 and hole 2 as a, the line segment a is on the straight line where the centers of holes 1 and 2 are located, and determine the center of hole 3 in the intersecting interval between hole 1 and hole 2 D3 and diameter d3, wherein the center D3 of hole three is located at the center of line segment a;

[0025] S3. Set the center and diameter of hole four, wherein the center of hole four coincides with hole three, and the diameter of hole four is d4=d3+0.05mm;

[0026] S4. Drilling the PCB board, taking the center D3 as the center, and processing the hole three...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com