Blind hole window manufacturing method capable of improving unfilled hole filling

A manufacturing method and a window-opening technology, which are applied in multilayer circuit manufacturing, printed circuit manufacturing, electrical components, etc., can solve the problems of blind holes being offset and tangent, deep depressions, and inability to fill, etc. The effect of reducing scrap and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to fully understand the technical content of the present invention, the technical solutions of the present invention will be further introduced and illustrated below in conjunction with specific examples, but not limited thereto.

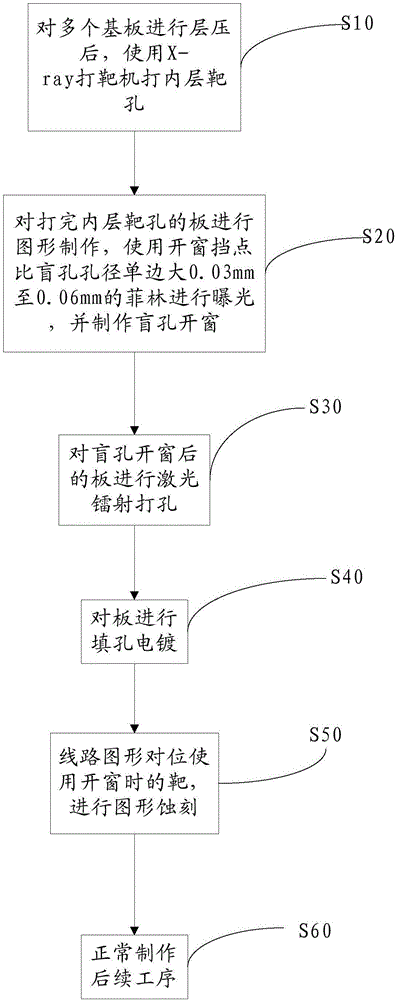

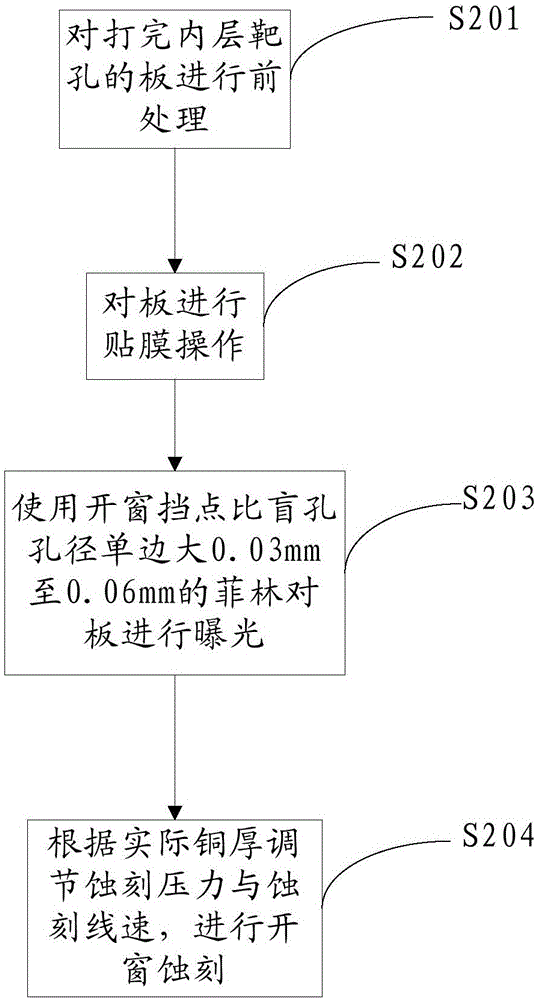

[0036] like Figure 1~2 As shown in the specific embodiment, this embodiment provides a blind hole opening method for improving incomplete hole filling, which can be used in the hole filling process of printed circuit boards to reduce window opening and reduce hole filling by electroplating. The difficulty of leveling, thus greatly reducing the scrapping of pad etching caused by poor sealing of blind holes when making outer graphics, saving costs and reducing scrapping. Specifically, it can be used in the production process of various multi-layer boards.

[0037] A blind hole window manufacturing method for improving insufficiency of hole filling, comprising the following steps:

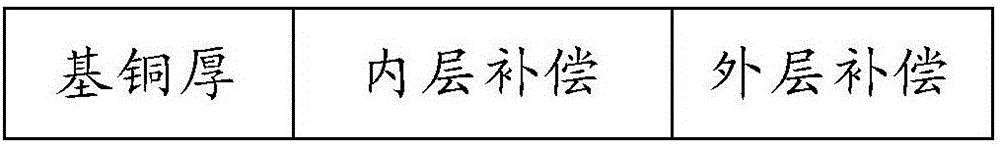

[0038] S10. After laminating multiple substrates, u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com