Method for preparing biligand film by utilizing in-situ electric field and biligand film prepared by method

A dual-ligand, electric field technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of reduced separation capacity, reduced separation performance, uneven dispersion, etc., to improve production efficiency and reduce costs. The effect of investing and simplifying the operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

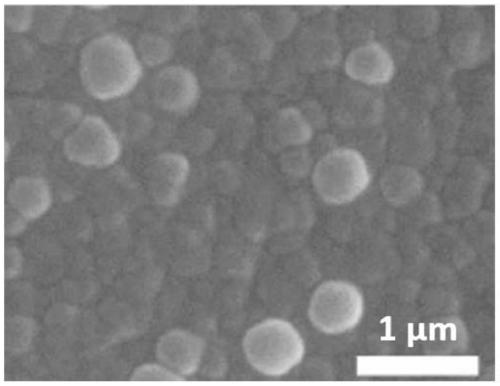

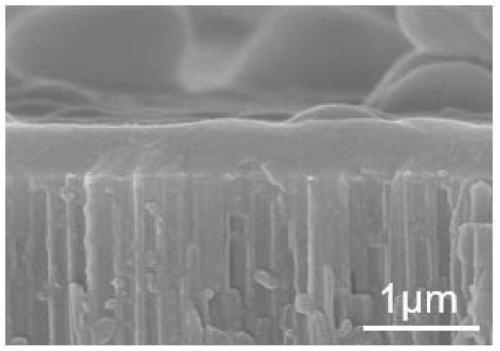

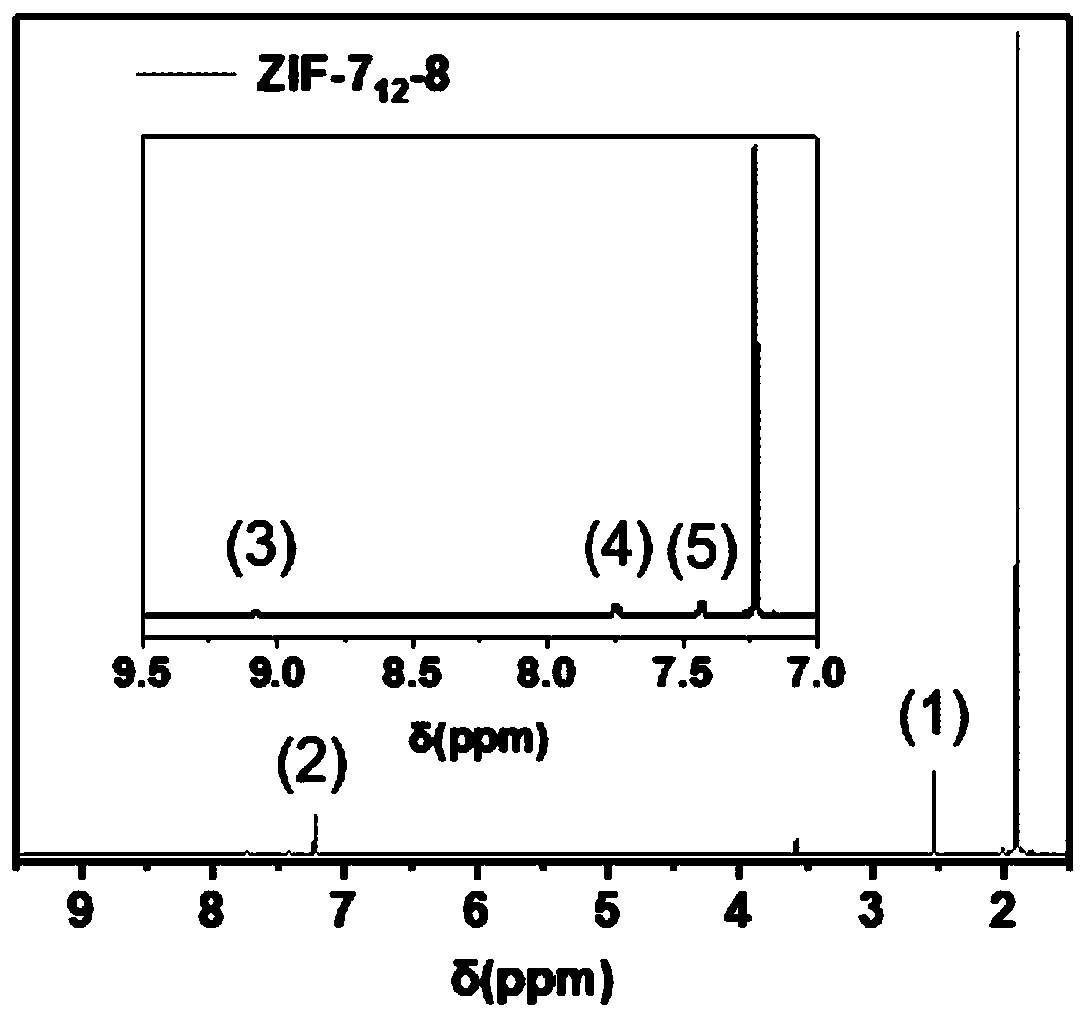

[0033] In this example, ZIF-7 was prepared in one step using the in-situ electric field method 12 -8 membrane, including the following steps:

[0034] (1) Solution A: Mix metallic zinc acetate dihydrate (0.21951g) and dimethylimidazole (0.1642g) and then ultrasonicate for 60s to dissolve it in 20 mL of methanol to obtain solution A.

[0035] (2) Solution B: Dissolve benzimidazole (11.814 mg) in 10 mL of dimethylformamide ultrasonically to obtain solution B. Add solution A to solution B, mix and stand for 2h to obtain a mixed solution and use it as ZIF-7 12 -8 film precursor.

[0036] (3) In-situ electric field next step synthesis ZIF-7 12 -8 Membrane: Immerse the porous anodic aluminum oxide (AAO) substrate into synthetic ZIF-7 12 -8 film precursor liquid, plus 0.7mA·cm -2 When reacting for 20 minutes at room temperature, ZIF-7 will be formed on the surface of AAO 12 -8 film.

[0037] Know ZIF-7 through RASPA 2.0 simulation calculation 12 -8 membrane pore size is

[0038] The resultin...

Embodiment 2

[0043] In this example, ZIF-7 was prepared in one step using the in-situ electric field method 22 -8 membrane, including the following steps:

[0044] (1) Solution A: Mix metallic zinc acetate dihydrate (0.21951g) and dimethylimidazole (0.1642g) and then ultrasonicate for 60s to dissolve it in 20 mL of methanol to obtain solution A.

[0045] (2) Solution B: Dissolve benzimidazole (29.535 mg) in 10 mL of dimethylformamide ultrasonically to obtain solution B. Add solution A to solution B, mix and stand for 3 hours to obtain a mixed solution and use it as ZIF-7 12 -8 film precursor.

[0046] (3) In-situ electric field next step synthesis ZIF-7 22 -8 Membrane: Immerse the porous anodic aluminum oxide (AAO) substrate into synthetic ZIF-7 22 -8 film precursor solution, plus 0.6mA·cm -2 When reacting for 15 minutes at room temperature, ZIF-7 will be formed on the surface of AAO 22 -8 film.

[0047] Know ZIF-7 through RASPA 2.0 simulation calculation 22 -8 membrane pore size is

[0048] The r...

Embodiment 3

[0053] In this example, ZIF-7 was prepared in one step using the in-situ electric field method 50 -8 membrane, including the following steps:

[0054] (1) Solution A: Mix metallic zinc acetate dihydrate (0.21951g) and dimethylimidazole (0.1642g) and then ultrasonicate for 60s to dissolve it in 20 mL of methanol to obtain solution A.

[0055] (2) Solution B: Dissolve benzimidazole (59.07 mg) in 10 mL of dimethylformamide ultrasonically to obtain solution B. Add solution A to solution B, mix and stand for 4 hours to obtain a mixed solution and use it as ZIF-7 12 -8 film precursor.

[0056] (3) In-situ electric field next step synthesis ZIF-7 50 -8 Membrane: Immerse the porous anodic aluminum oxide (AAO) substrate into synthetic ZIF-7 50 -8 film precursor solution, plus 0.5mA·cm -2 When reacting for 25min at room temperature, ZIF-7 will be formed on the surface of AAO 50 -8 film.

[0057] Know ZIF-7 through RASPA 2.0 simulation calculation 12 -8 membrane pore size is

[0058] The resulti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com