Patents

Literature

38results about How to "Reduce window size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

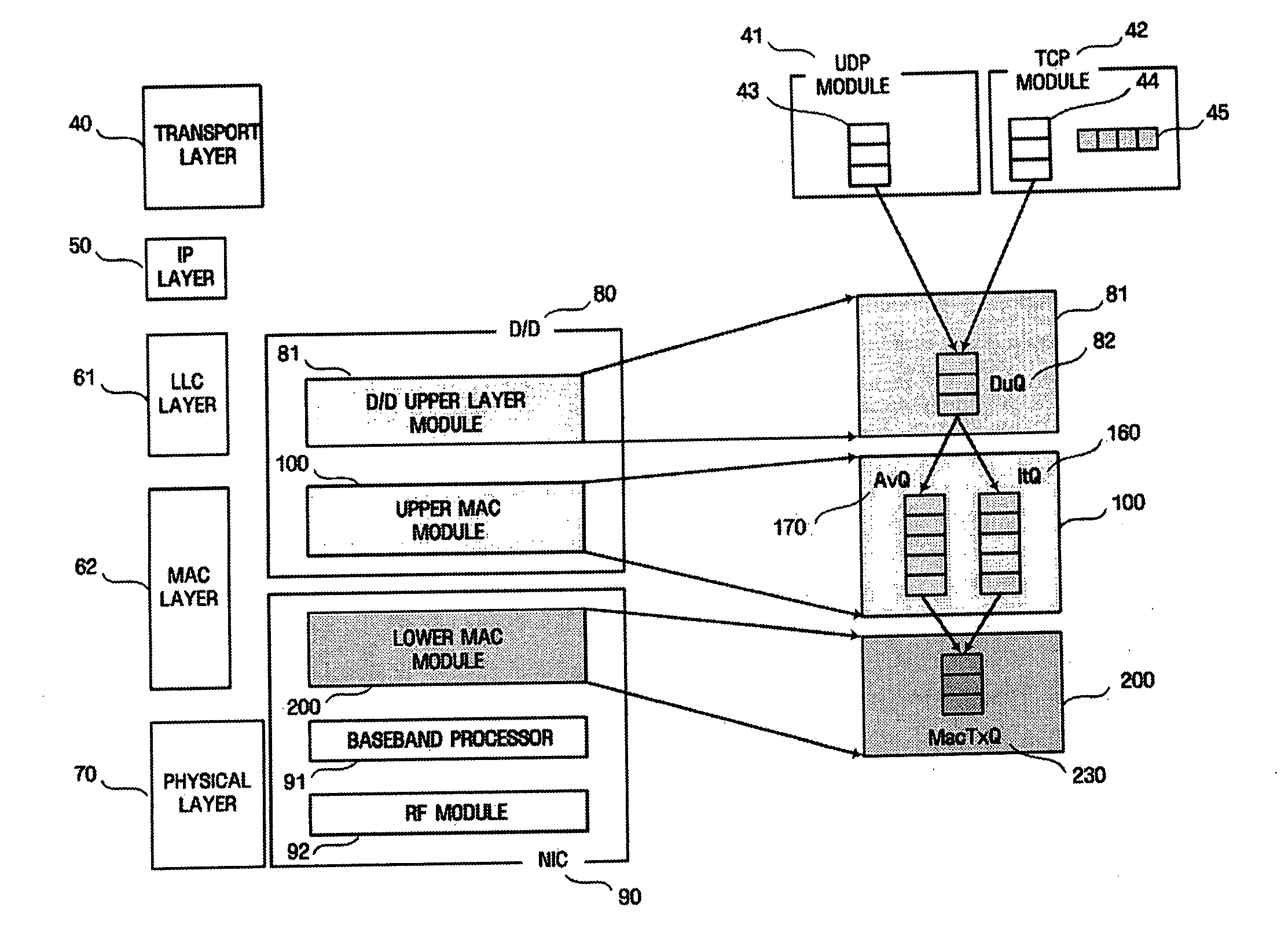

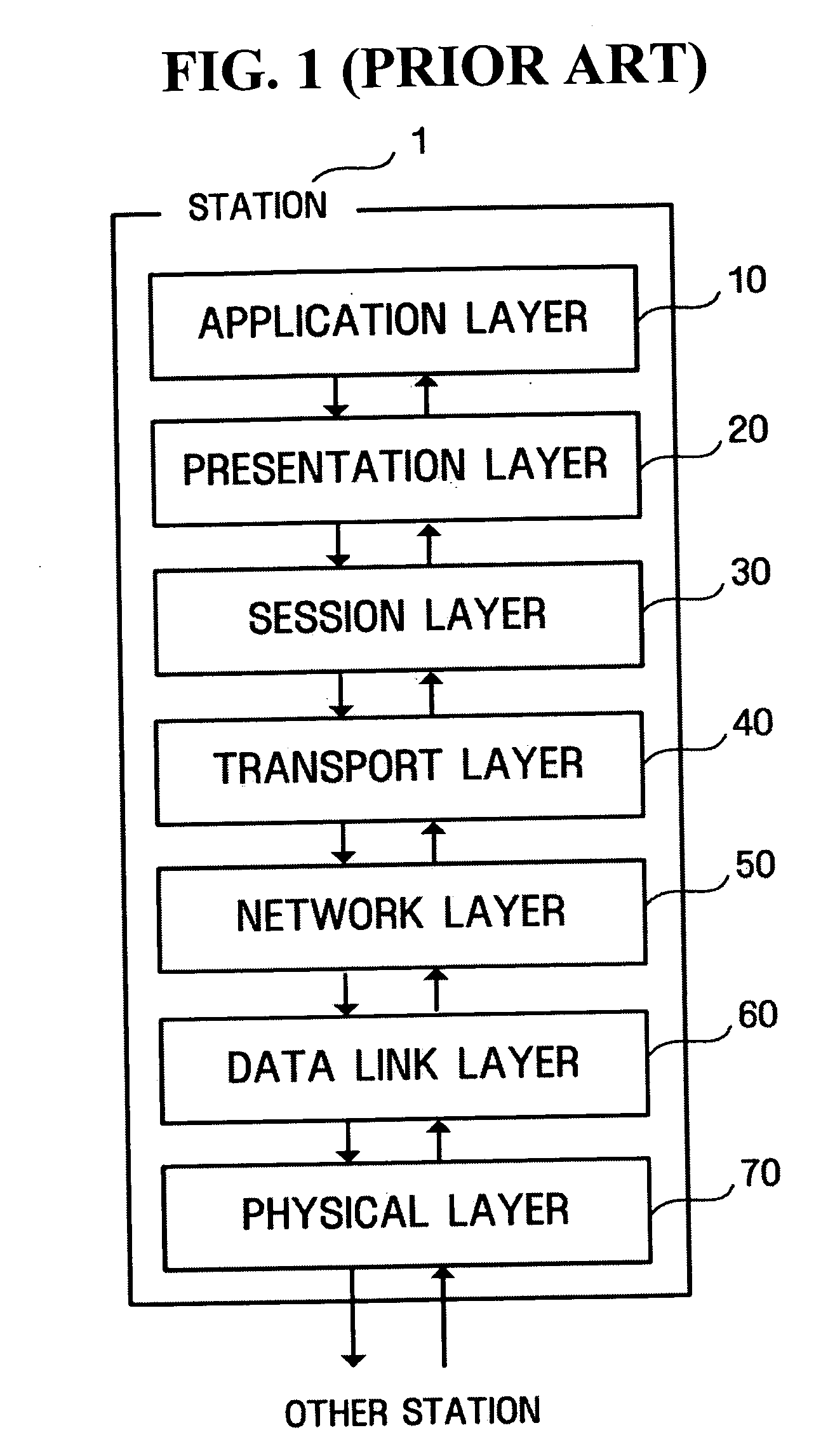

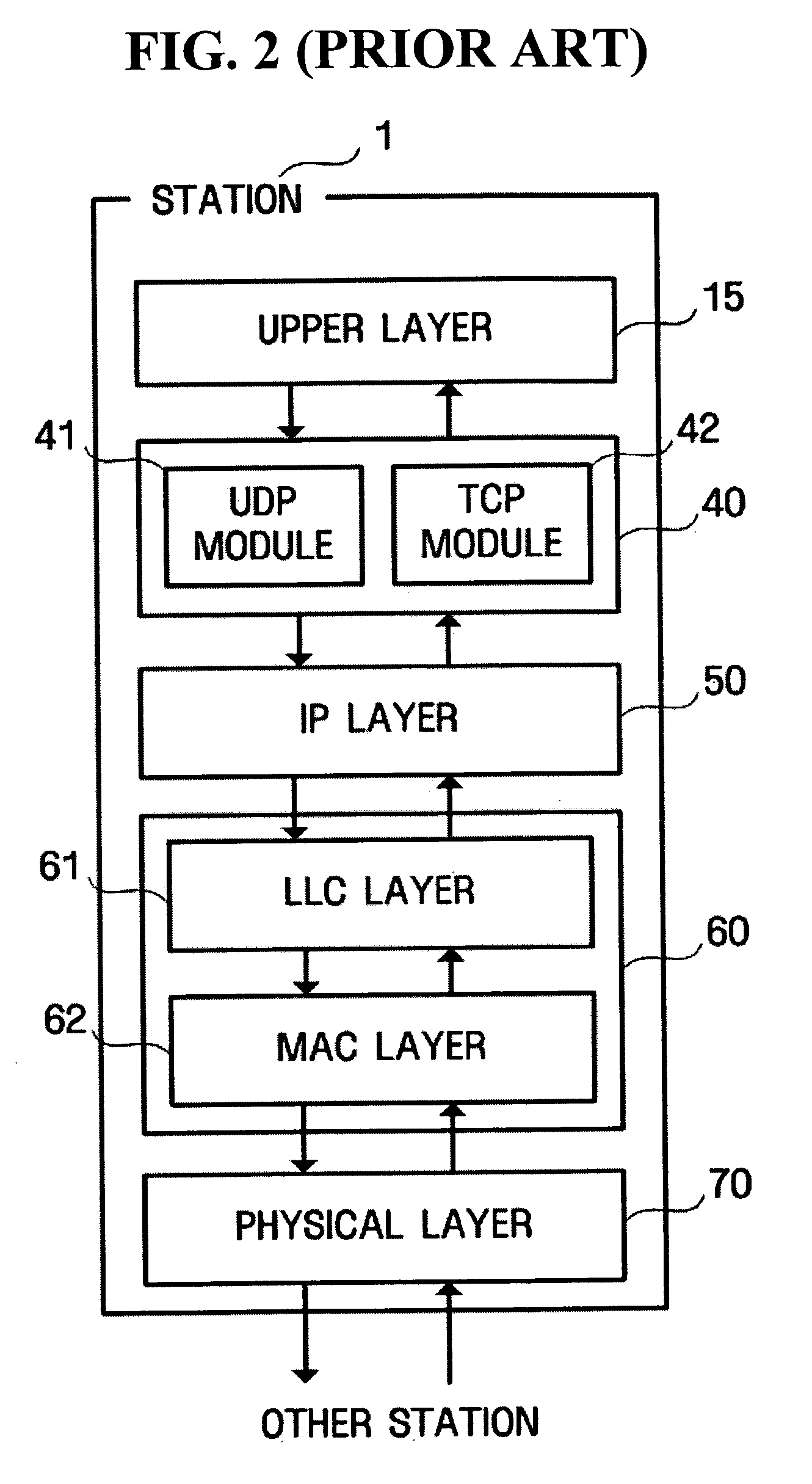

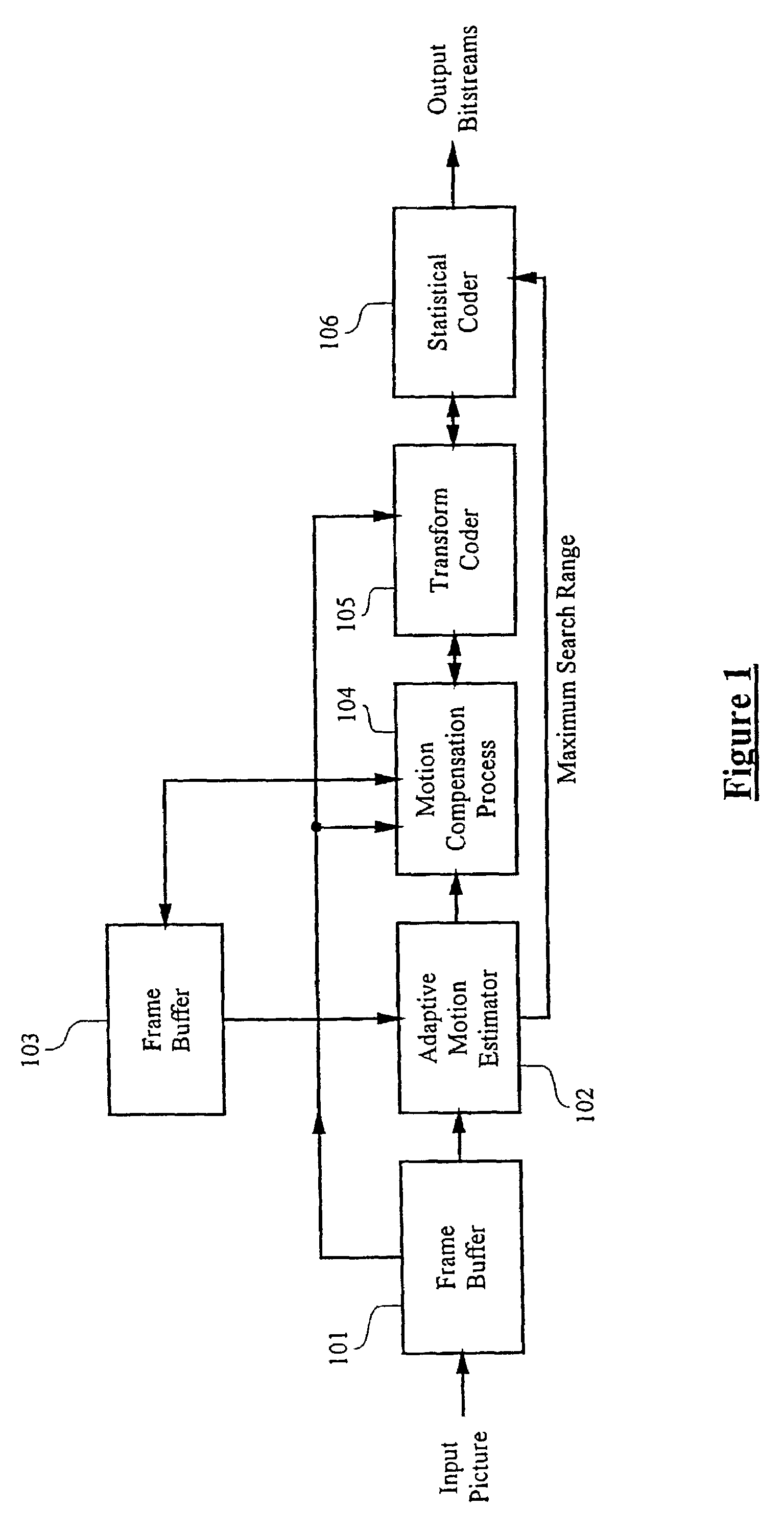

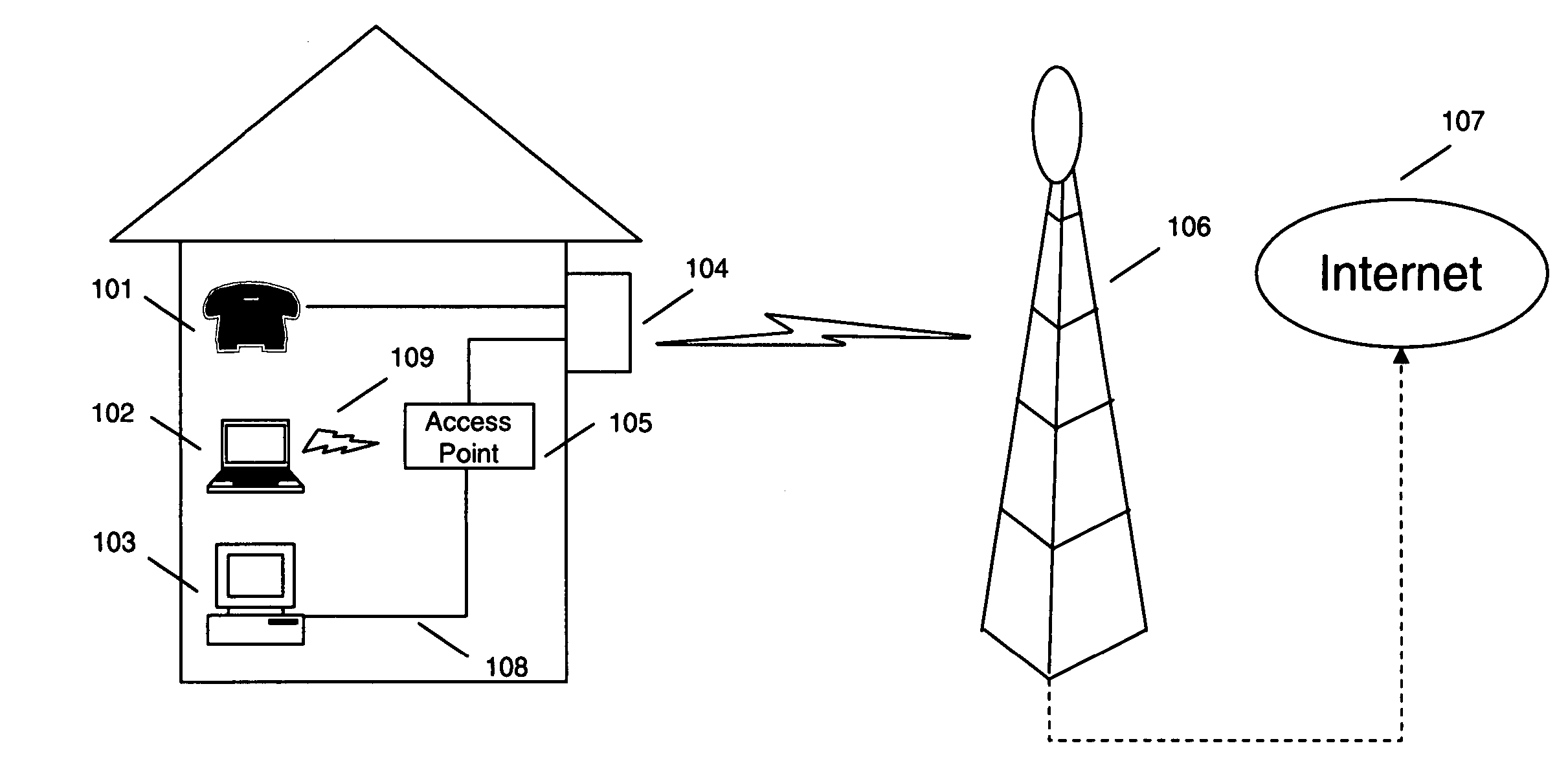

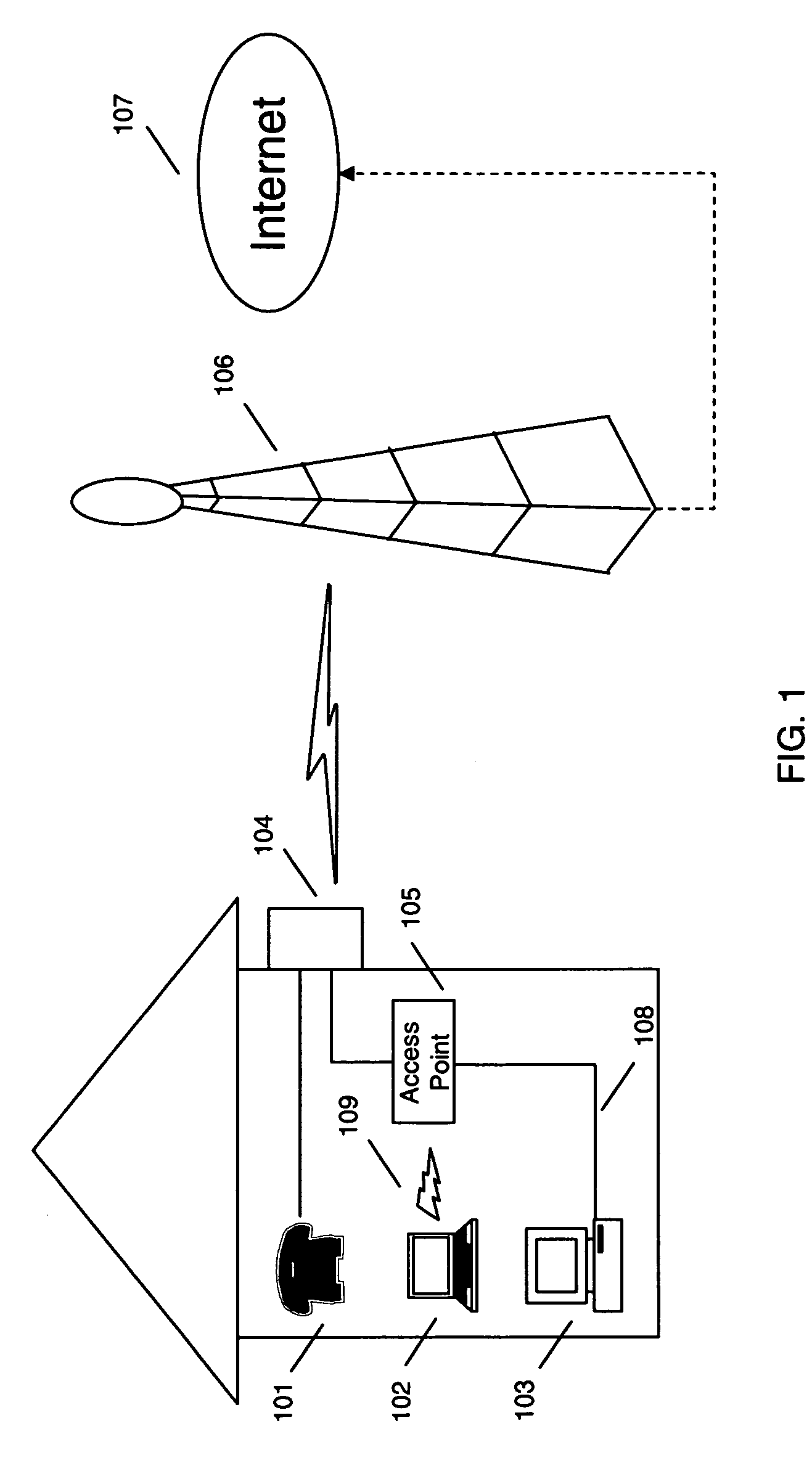

Method and apparatus for dynamically controlling traffic in wireless station

InactiveUS20050195821A1Reduce window sizeGuaranteed normal transmissionNetwork traffic/resource managementData switching by path configurationMultimedia streamsControl data

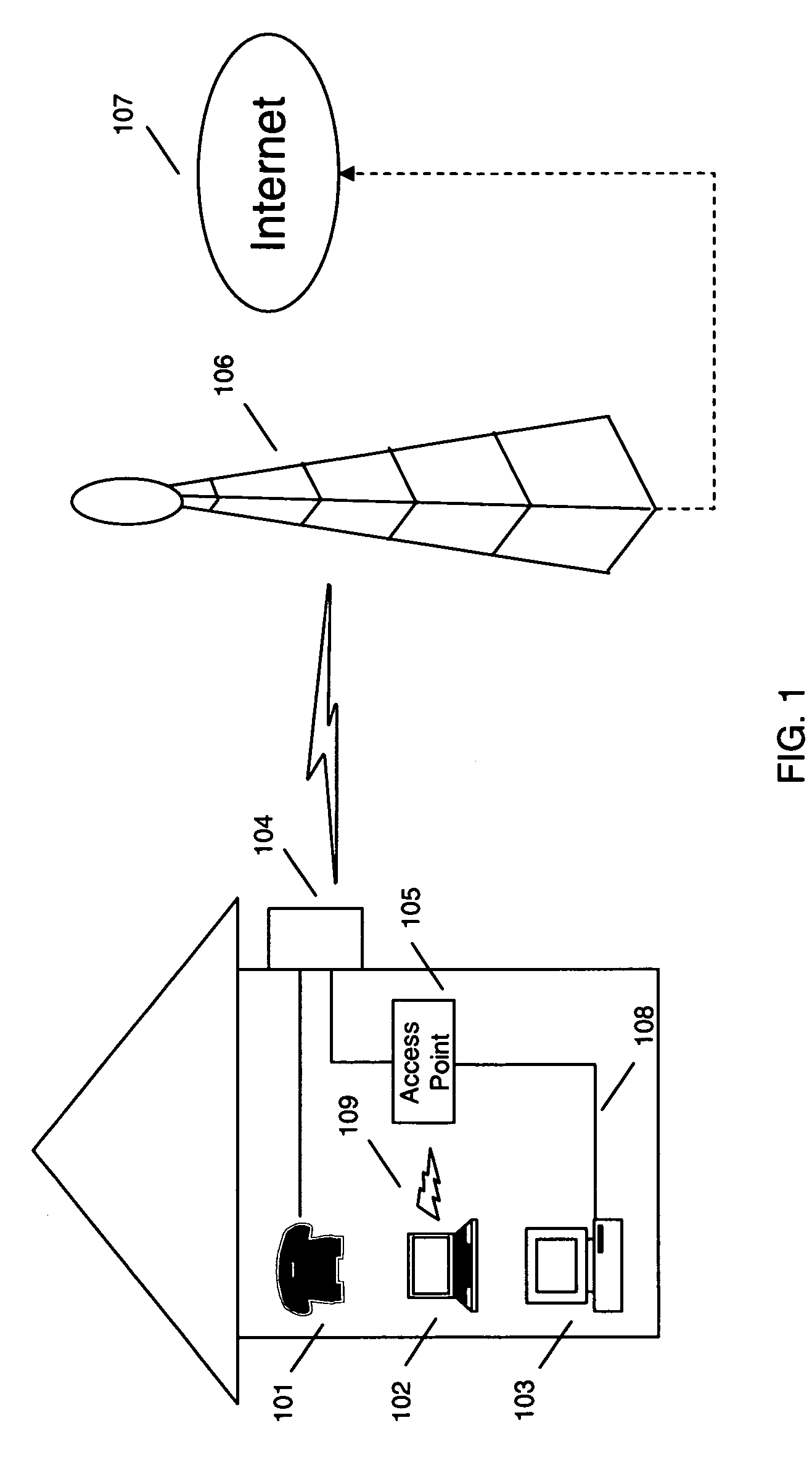

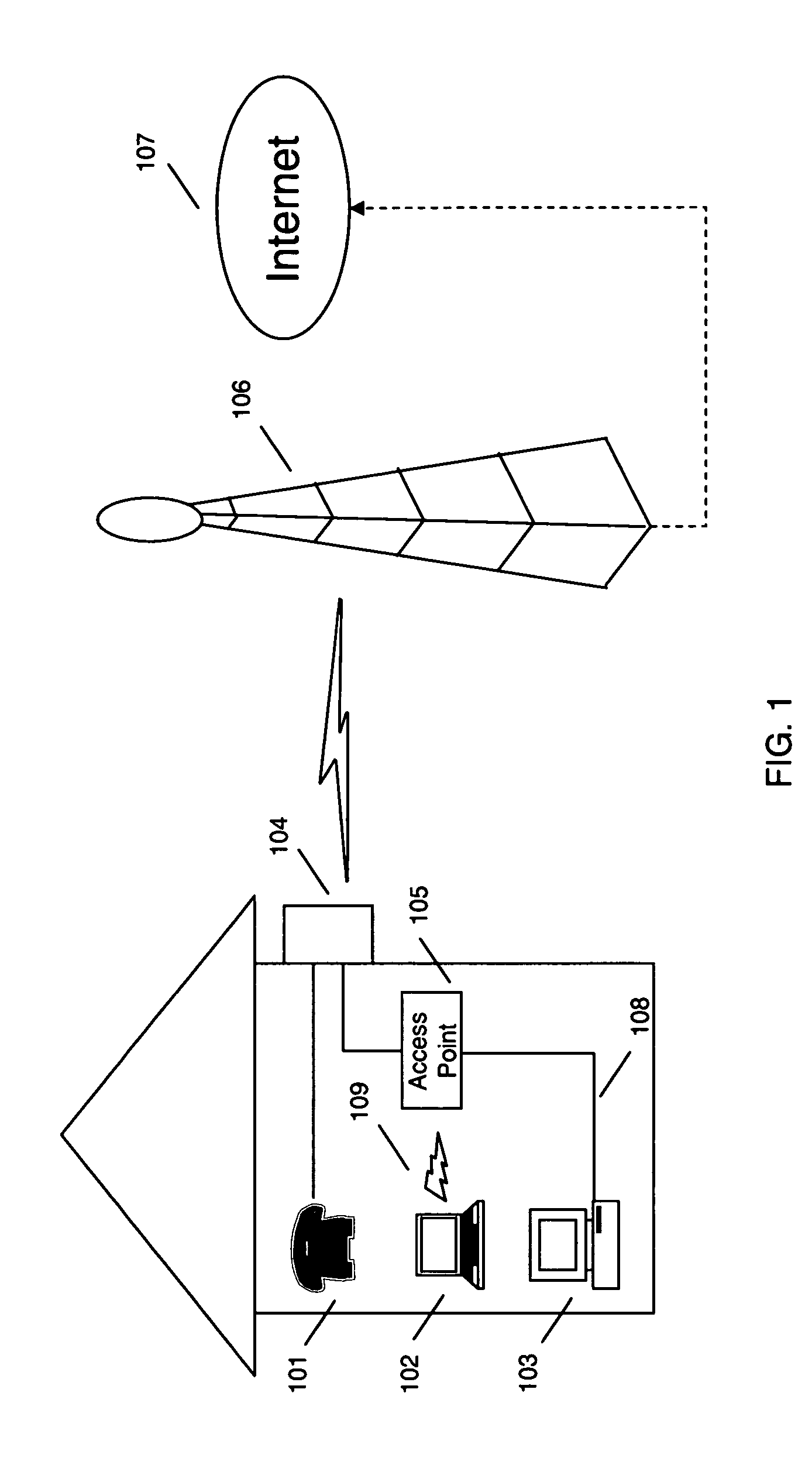

A method and apparatus dynamically control data traffic, such as multimedia streams, needing a guaranteed Quality of Service (QoS) and normal data traffic, according to a variable communication environment. The method of dynamically controlling traffic in a wireless station includes reading header information of a packet received from an upper layer and determining a type of the packet, setting a priority according to the type of the packet, adjusting a size of a variable buffer by performing appropriate dynamic buffering according to the type of the packet, enqueuing the packet in a fixed buffer if the priority is high and enqueuing the packet in the variable buffer if the priority is low, and transmitting the packet enqueued in the fixed buffer to a destination station prior to the packet enqueued in the variable buffer.

Owner:SAMSUNG ELECTRONICS CO LTD

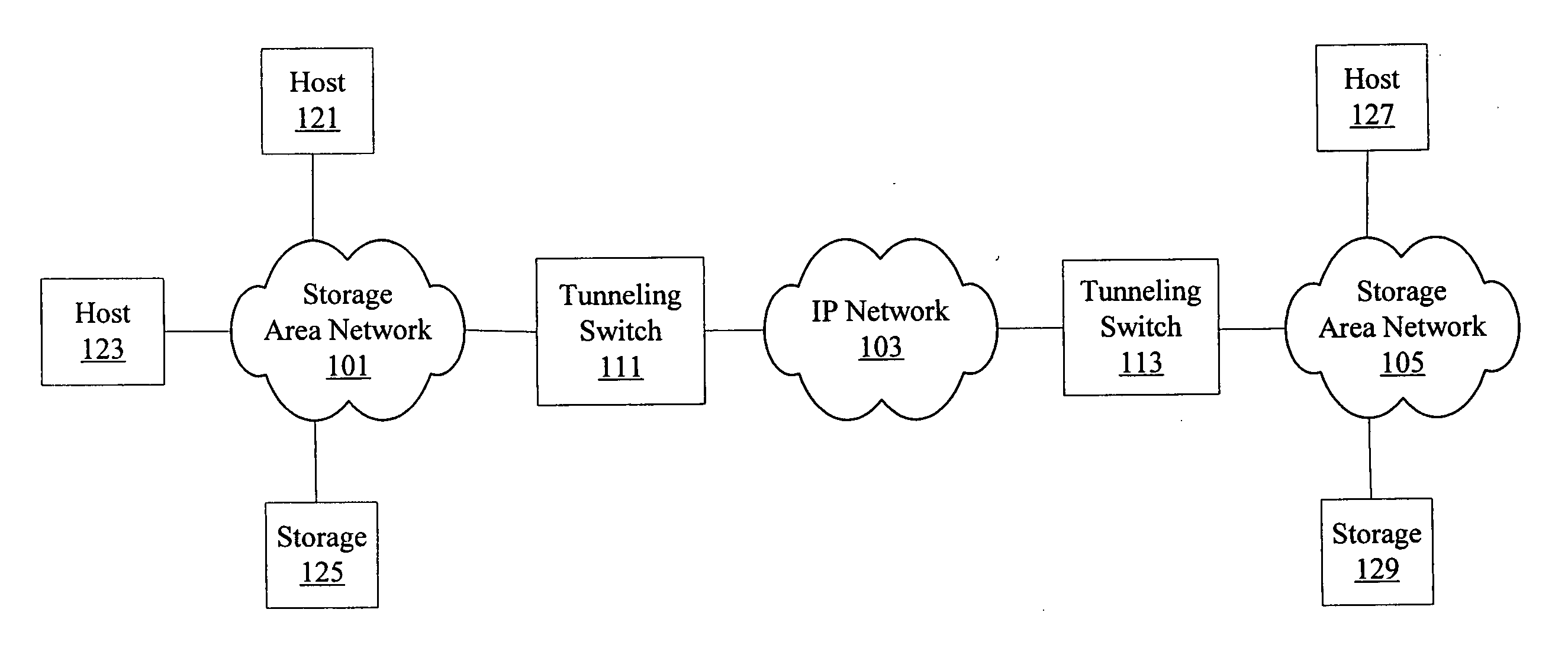

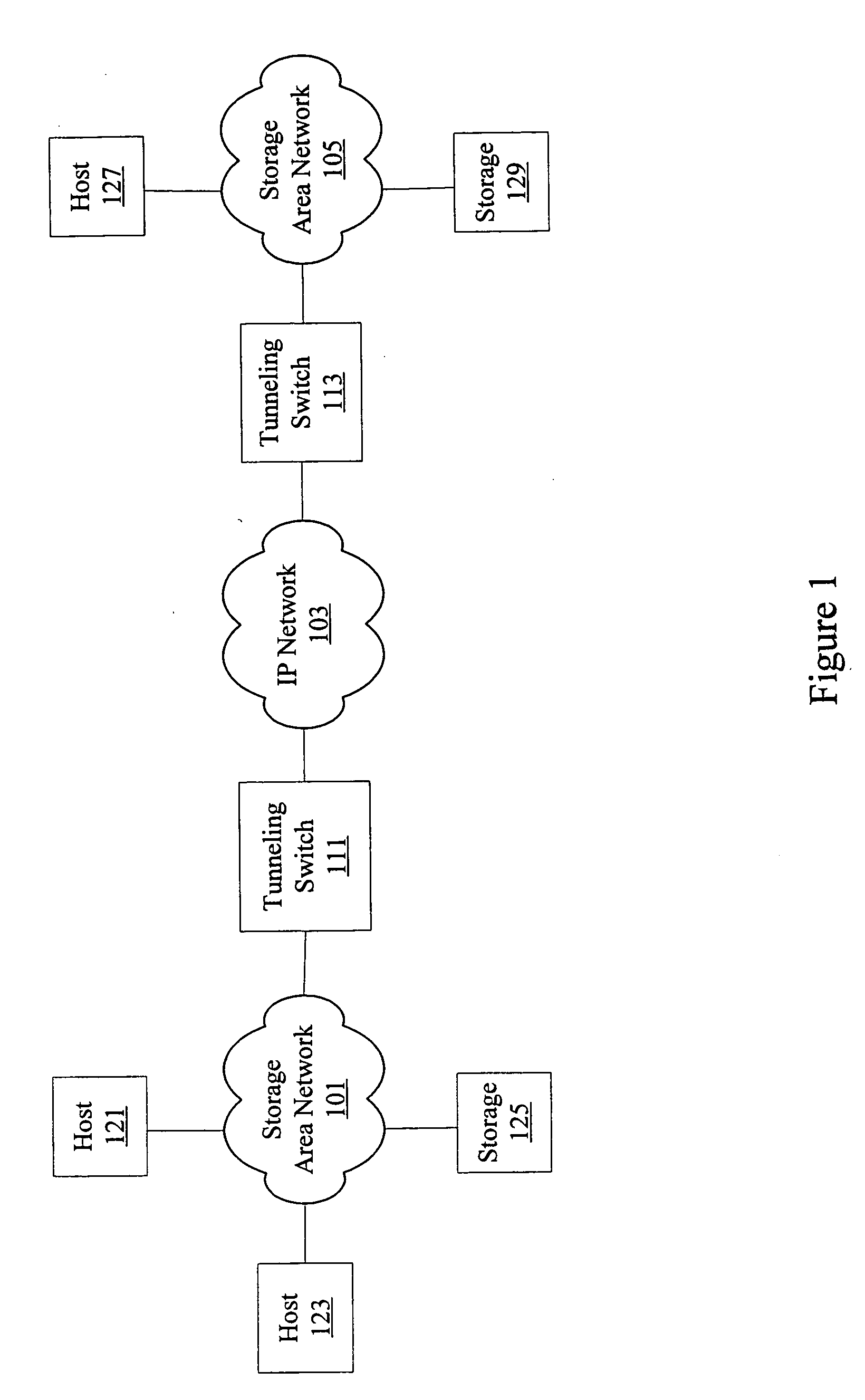

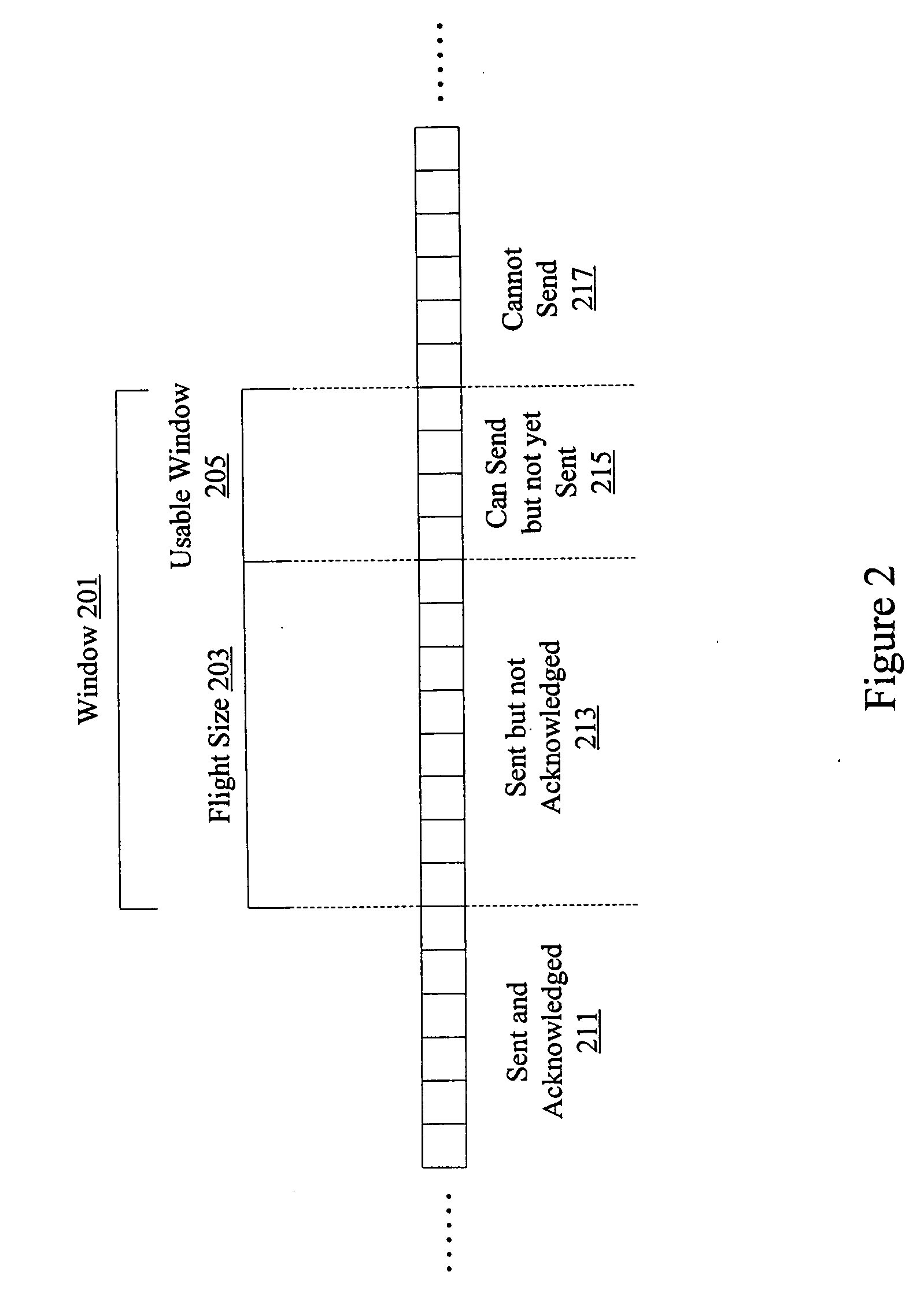

Transmission control protocol (TCP) congestion control using transmission delay components

InactiveUS20070121511A1Reduce window sizeError preventionFrequency-division multiplex detailsTransmission delaySize increase

According to the present invention, methods and apparatus are provided to improve the Transmission Control Protocol (TCP) for data such as delay sensitive or bursty data. A maximum send window is adjusted using forward queuing delay and maximum bandwidth parameters. Reverse queuing delay and the number of packets drops are not factored into generation of the maximum send window. Network buffer occupation is bounded and a congestion window is effectively varied using rate shaping and gradual size increases based at least partially on the number acknowledged packets.

Owner:CISCO TECH INC

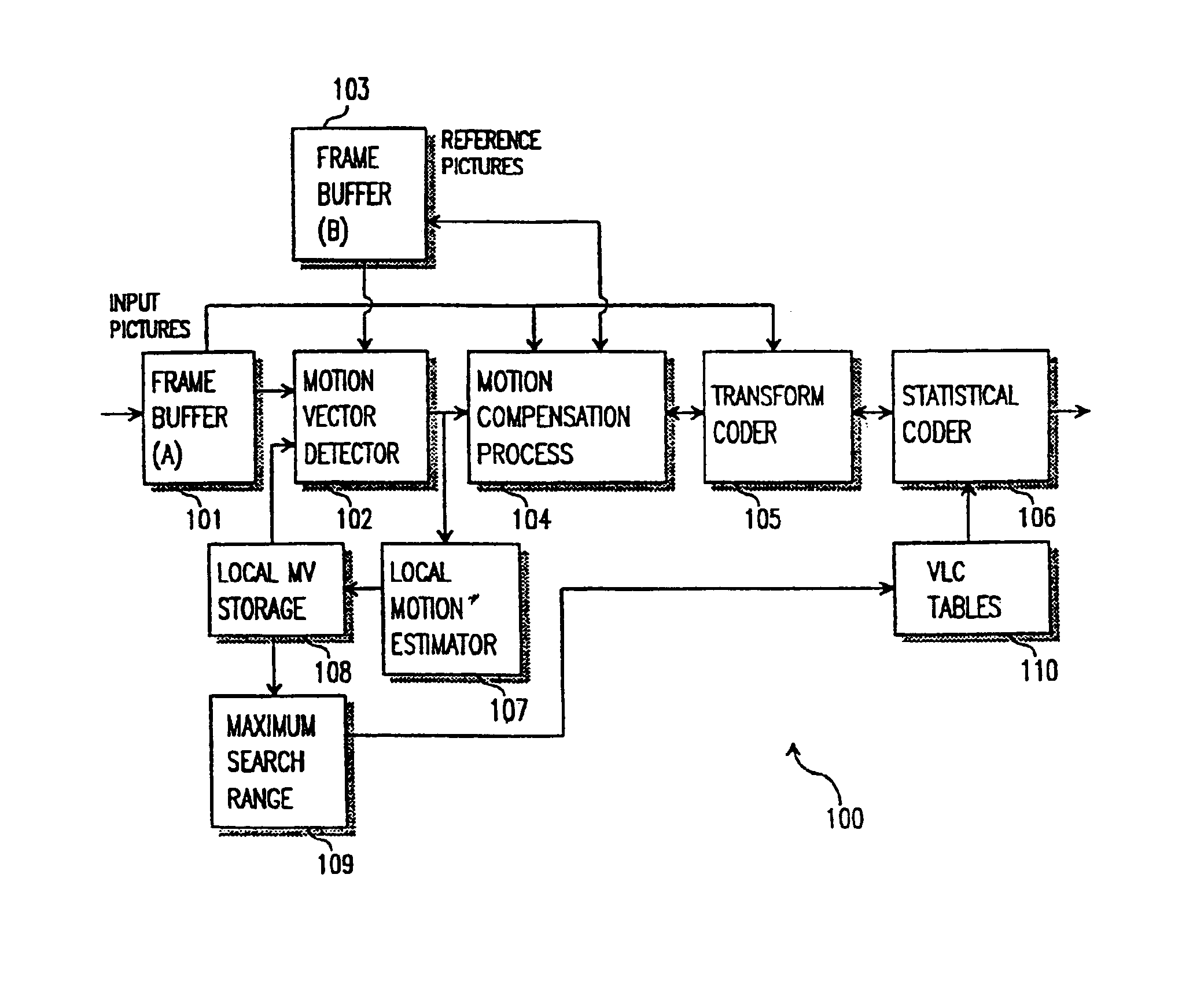

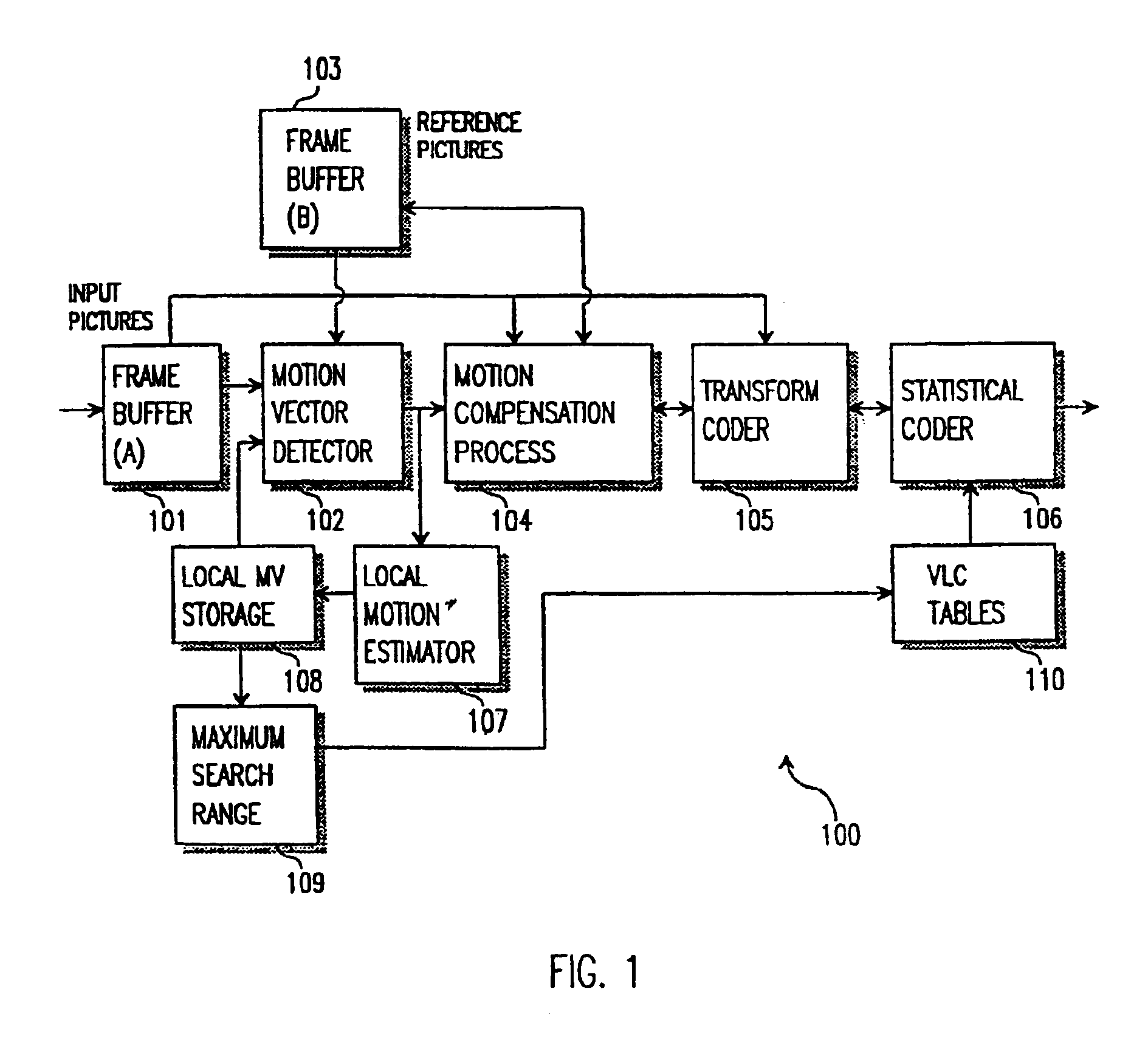

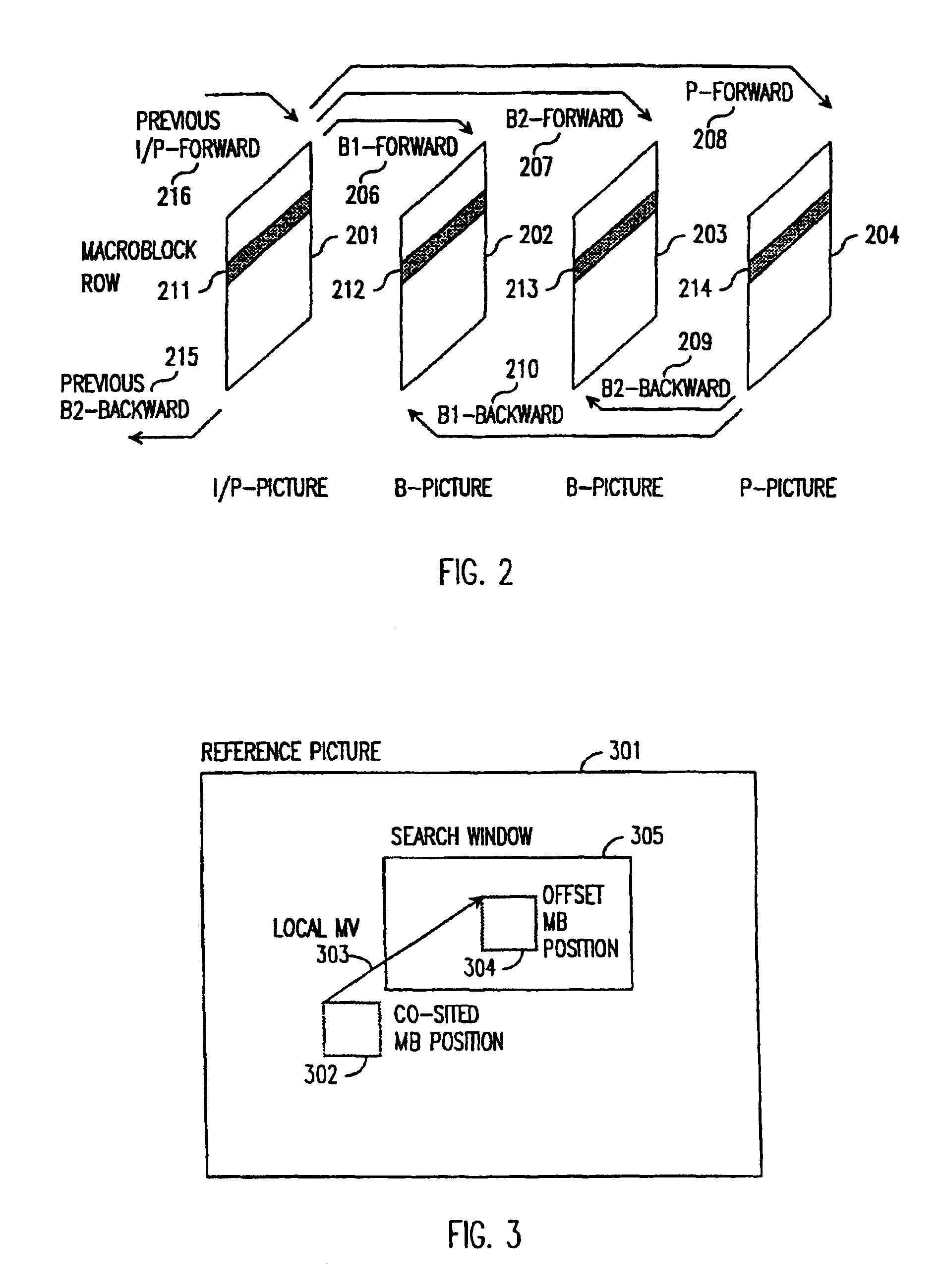

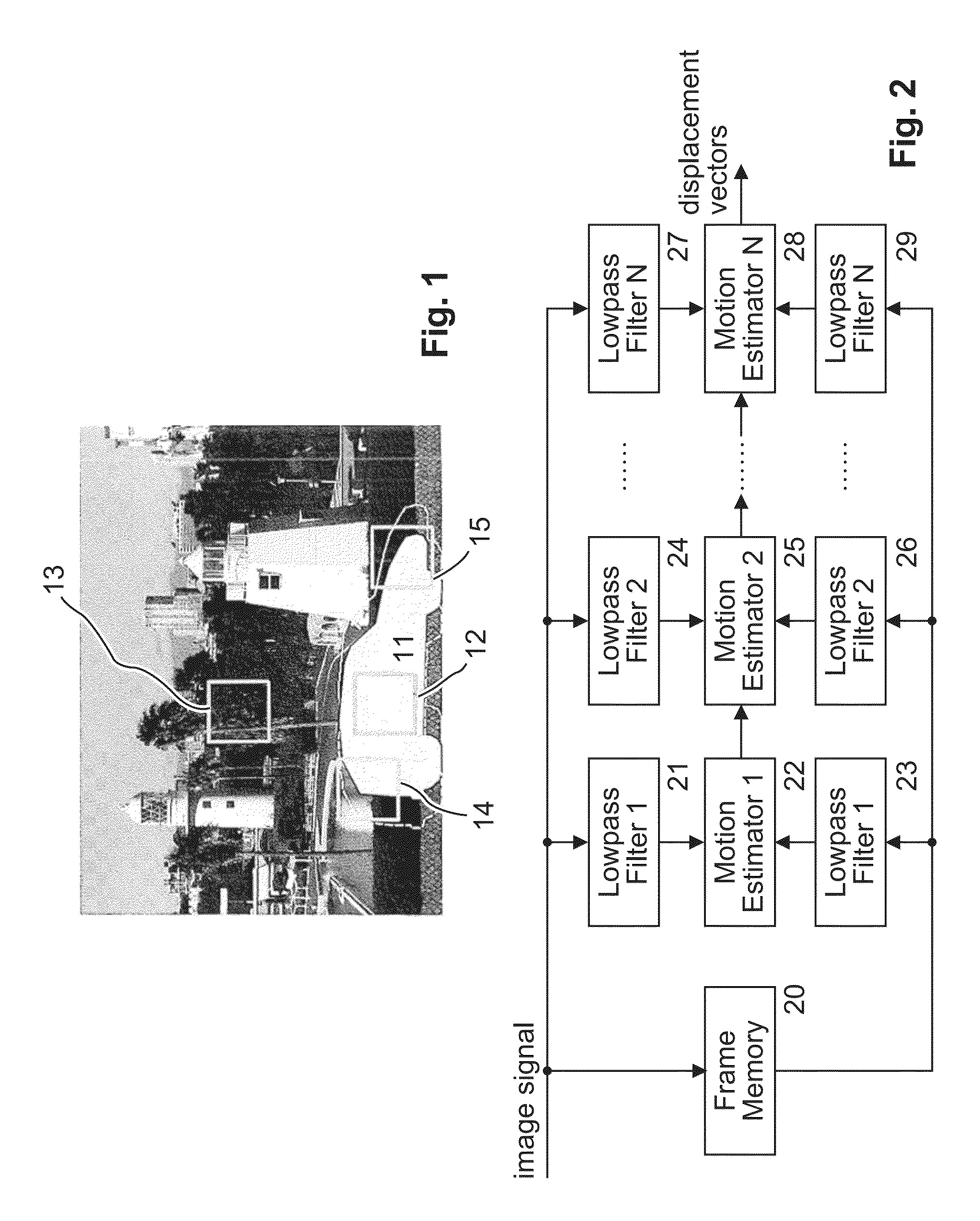

Motion vector detection with local motion estimator

InactiveUS6876702B1Increase the search rangeMinimized search windowColor television with pulse code modulationColor television with bandwidth reductionDigital videoMPEG-1

A method and apparatus of encoding digital video, for example according to the ISO / IEC MPEG standards (ISO / IEC 11172-2 MPEG-1 and ISO / IEC 13818-2 MPEG-2), which employs a local motion estimator for determining respective local motion vectors for groups of adjacent macroblocks in a picture. A local motion vector is determined for each row of macroblocks in a picture from the motion vectors of the macroblocks in that row. Then, for macroblocks in the corresponding row of a subsequently coded picture, the local motion vector can be used to select the search window used for determining the motion vectors. The local motion estimator improves search range and accuracy of macroblock motion vector detection without increasing the search window accessing bandwidth and caching requirement, and computation lode of searching.

Owner:STMICROELECTRONICS ASIA PACIFIC PTE

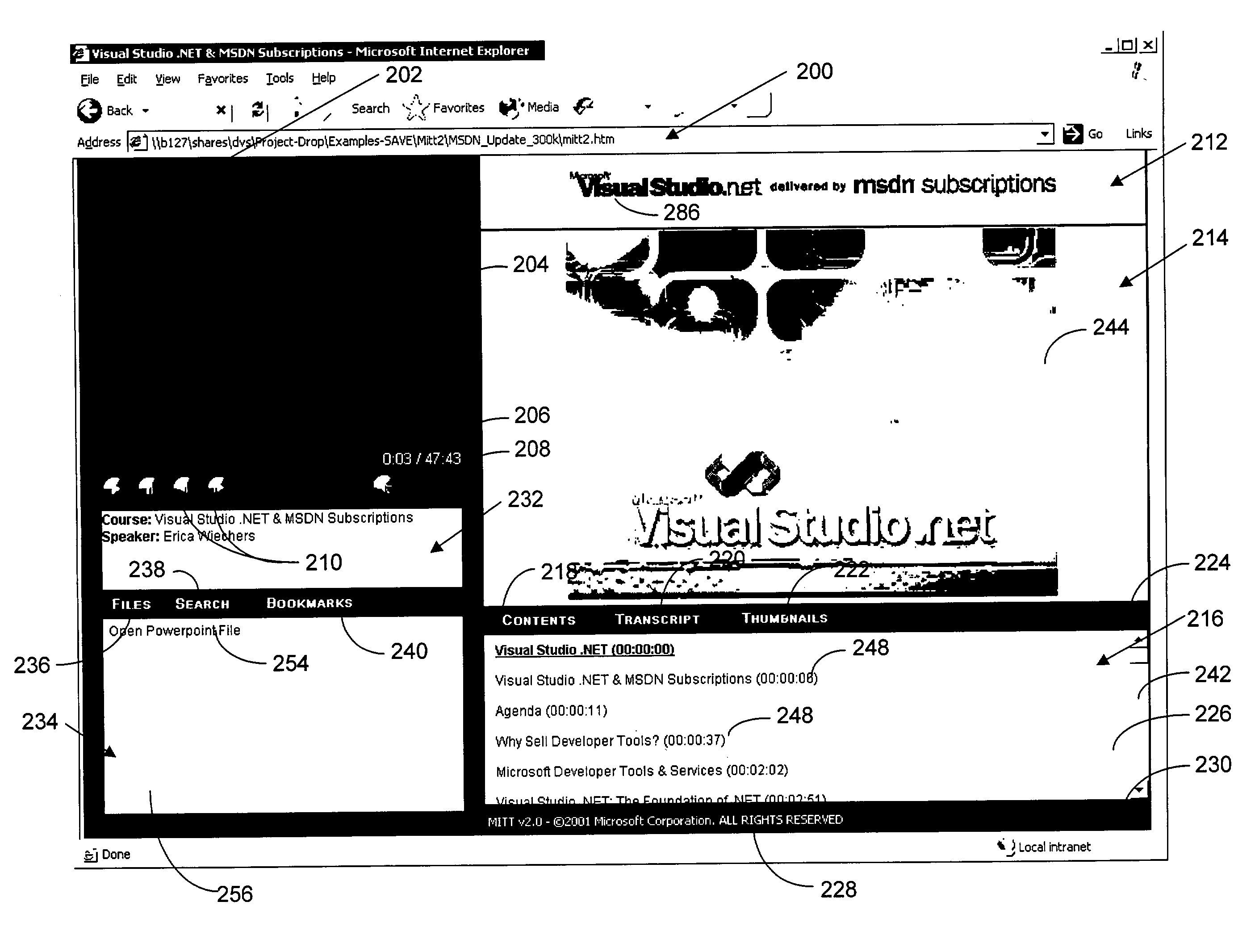

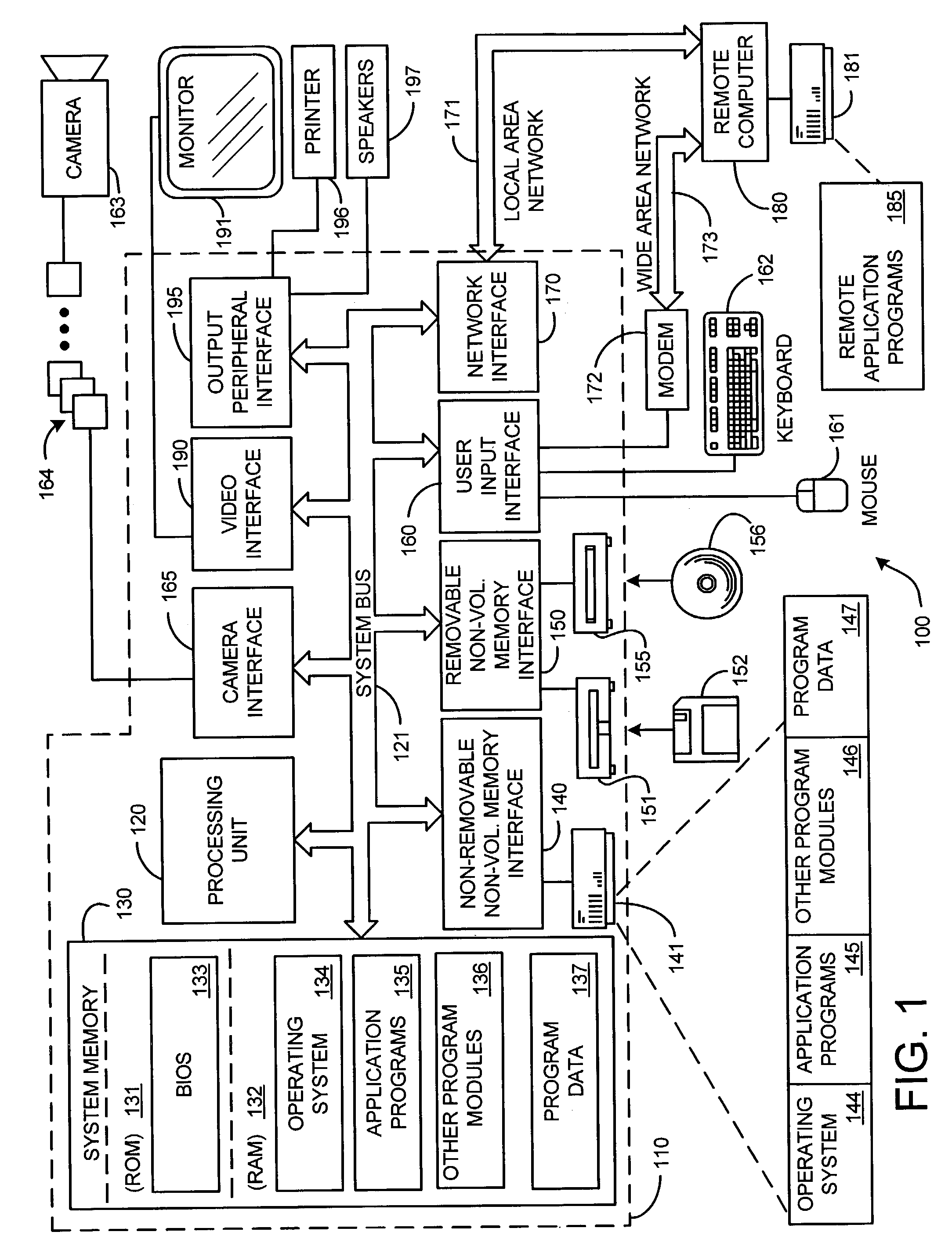

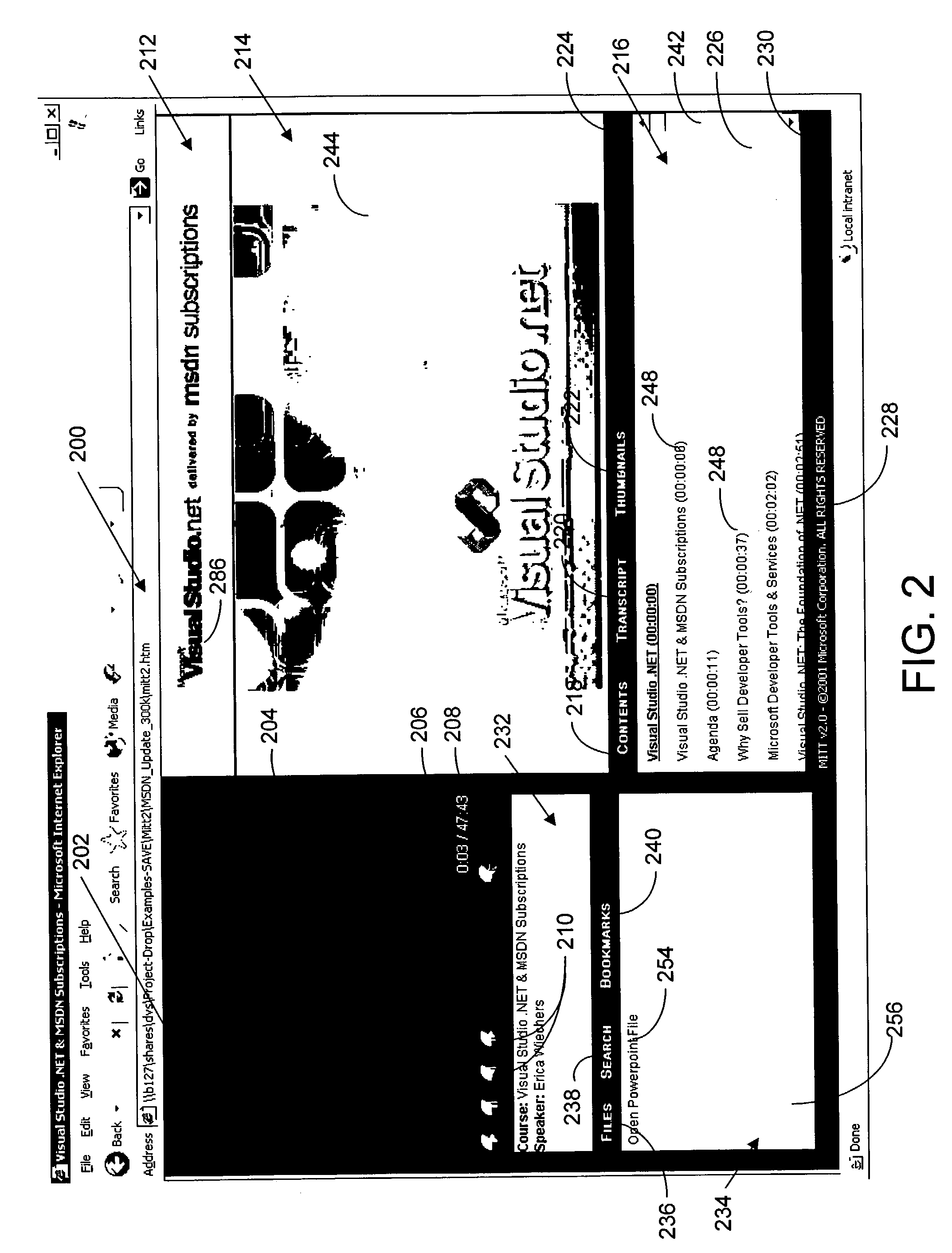

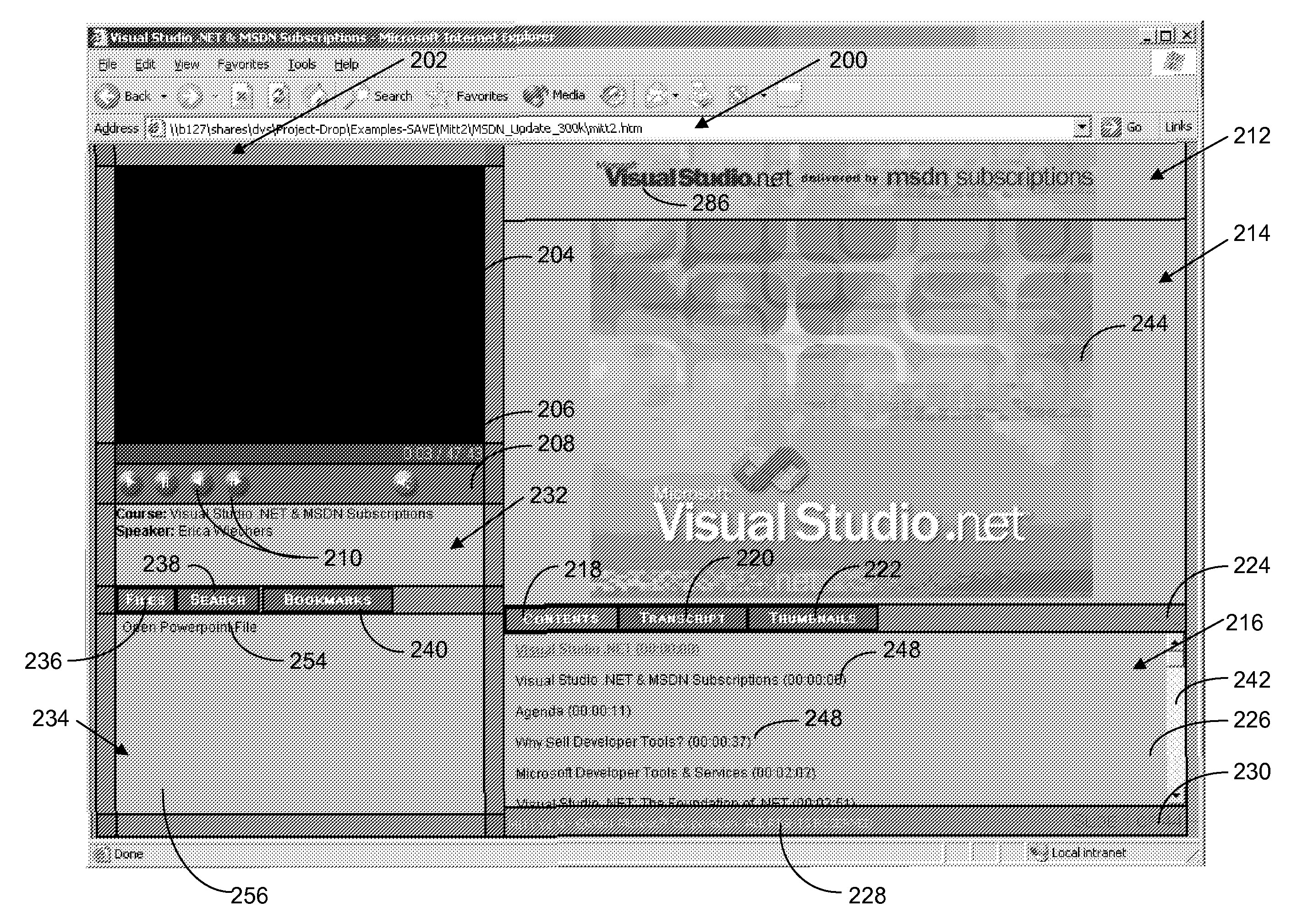

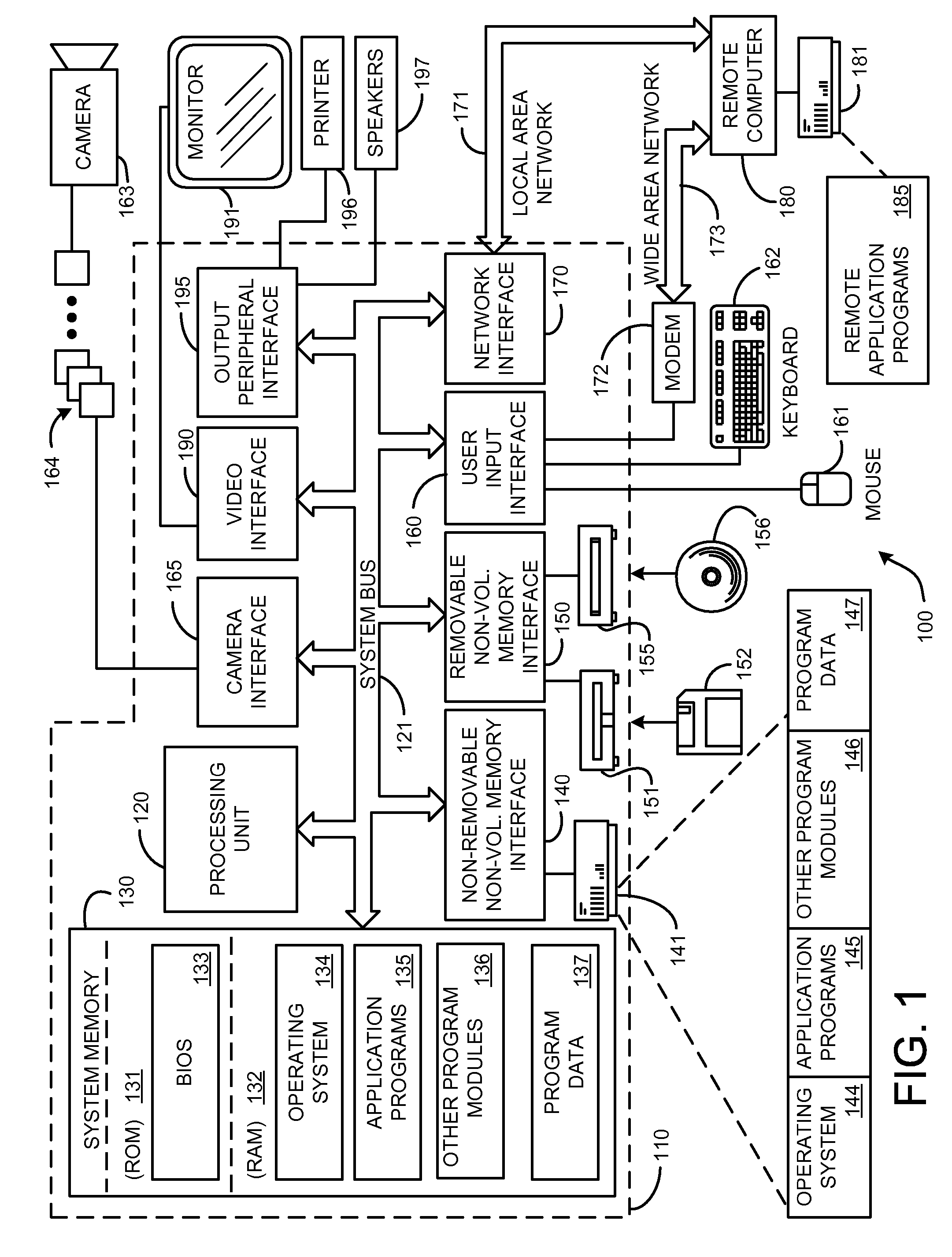

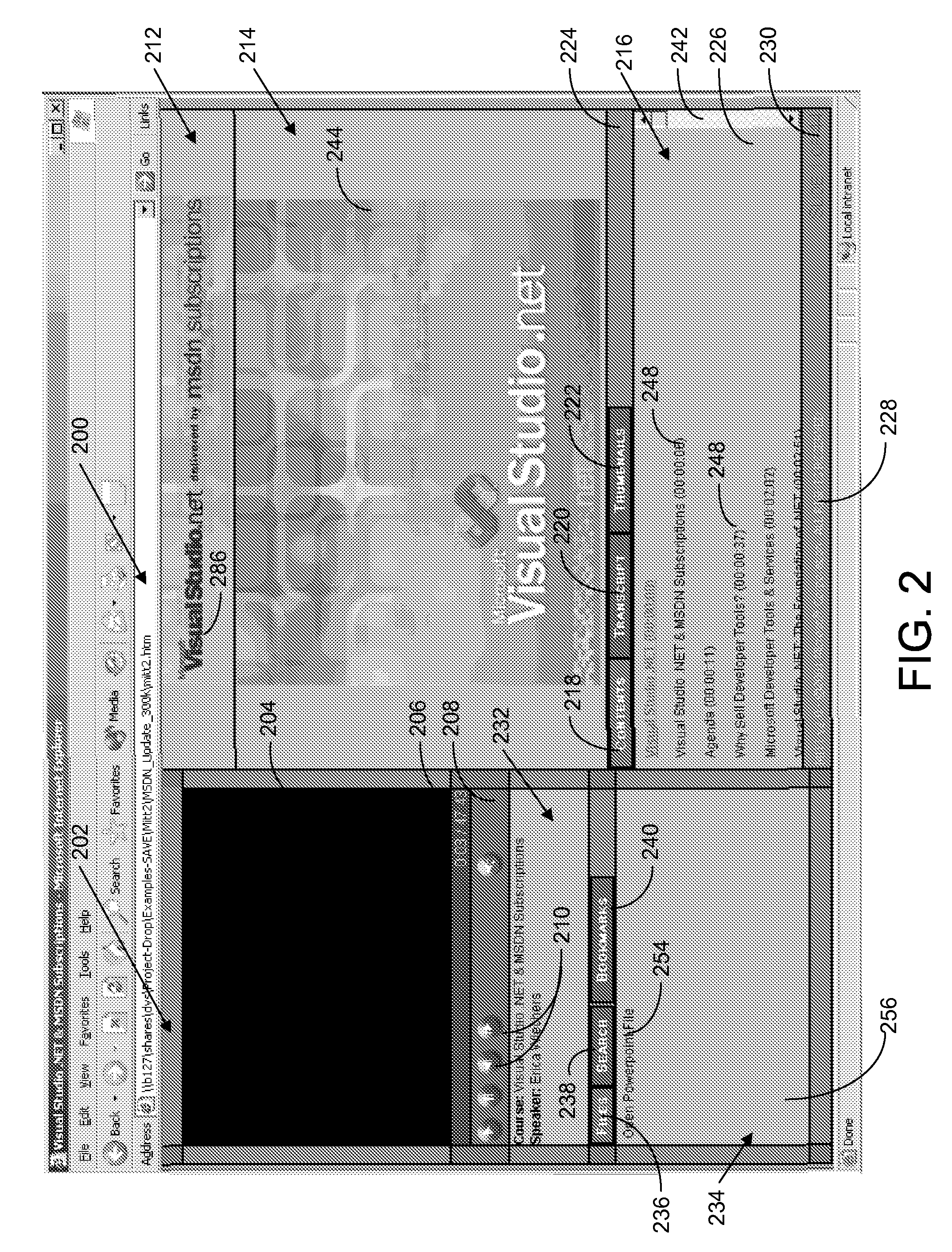

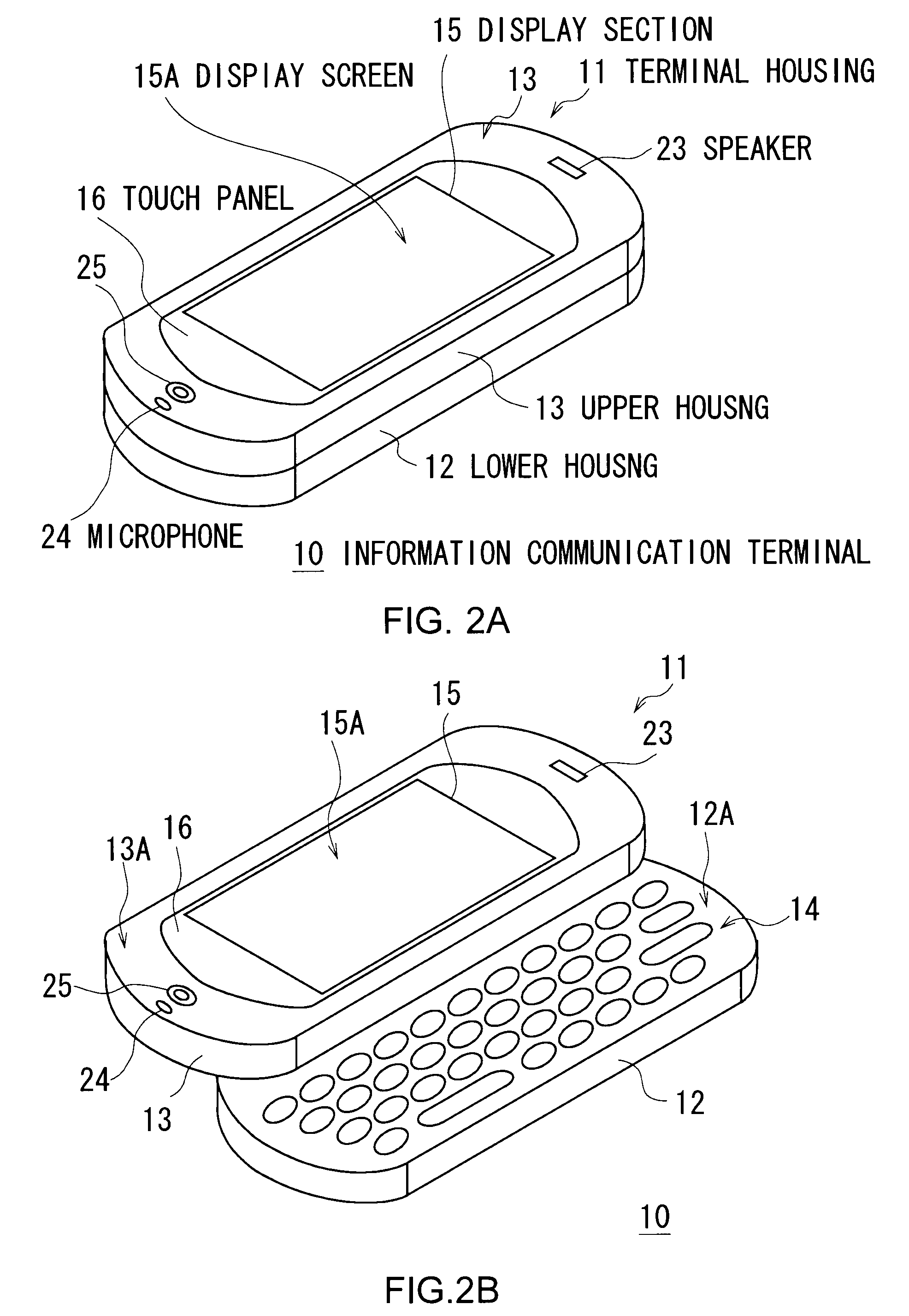

Interactive presentation viewing system employing multi-media components

InactiveUS7496845B2Increase or decrease sizeReduce window sizeTelevision system detailsColor television detailsGraphicsText display

An interactive, multi-media presentation viewing system and process for viewing educational or business presentations integrating presentation graphics in the form of presentation slides, video, audio, text, and other streaming media into a powerfully coordinated viewing experience for the end user. The viewing system is an aggregate of synchronized presentation graphics, video, and text displays employing a graphical user interface that allows the user to control all aspects of media playback.

Owner:MICROSOFT TECH LICENSING LLC

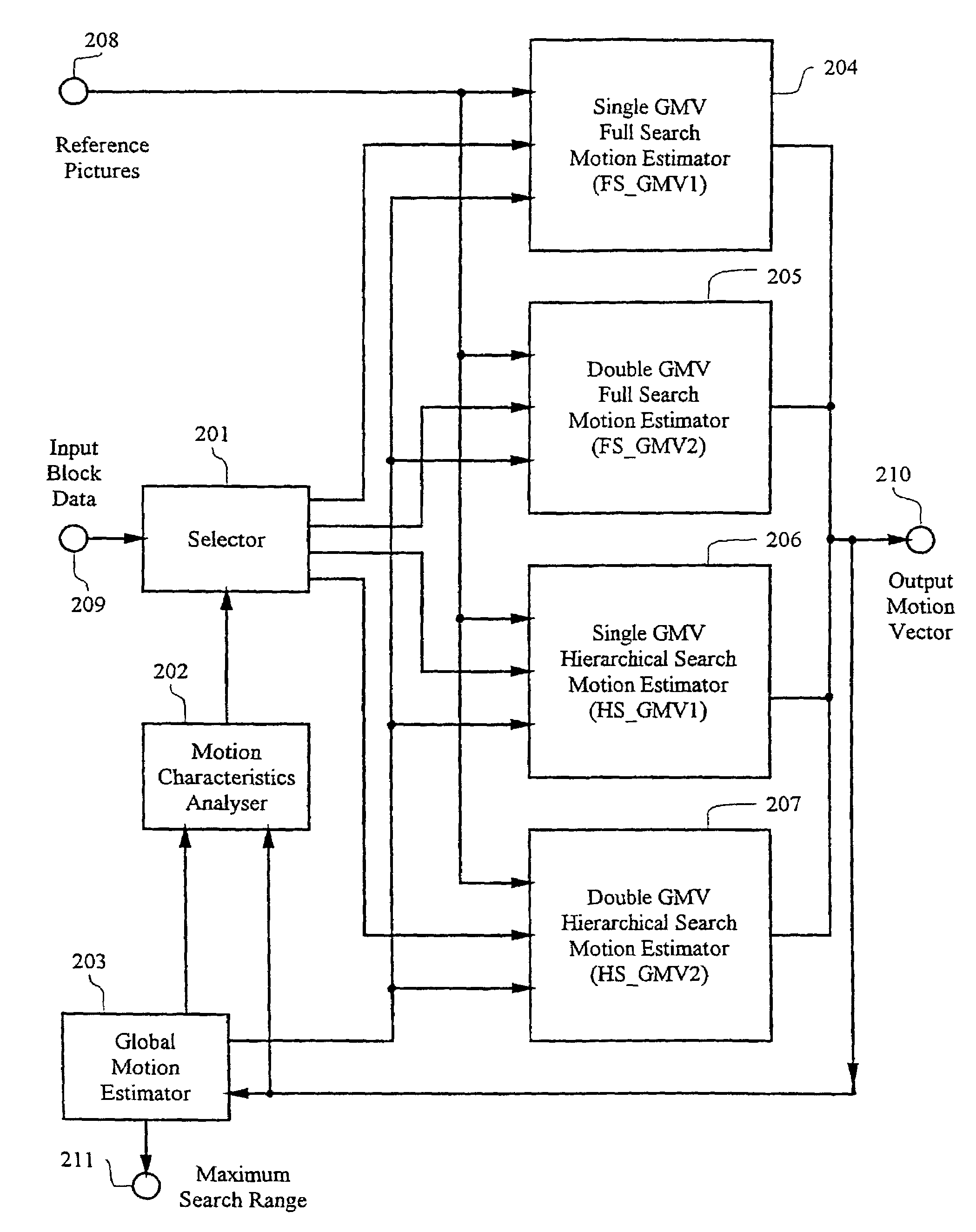

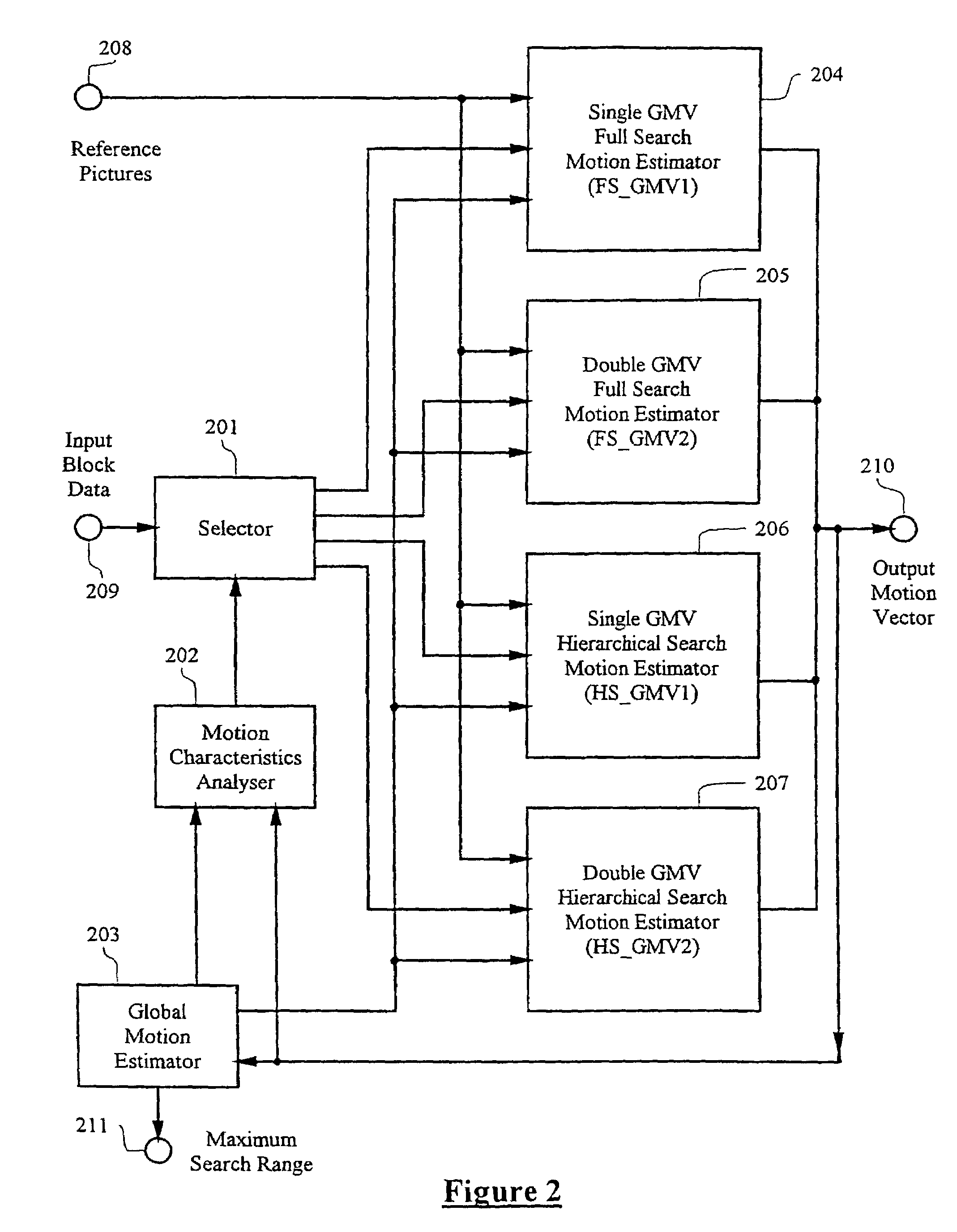

Adaptive motion estimator

InactiveUS7551673B1Expand effective search rangeMeet growth requirementsColor television with pulse code modulationImage analysisDigital videoMPEG-1

A method and apparatus of encoding digital video according to the ISO / IEC MPEG standards (ISO / IEC 11172-2 MPEG-1 and ISO / IEC 13818-2 MPEG-2) using an adaptive motion estimator. A plurality of global motion vectors are derived from the motion vectors of a previous picture in a sequence, and the global motion vectors are analyzed to determine motion characteristics. The video encoding is arranged to enable switching among different types of local motion estimators based on the motion characteristics of the moving pictures sequence. This gives rise to a motion estimation algorithm that can adaptively change its search range, search area and block matching scheme to suit different types of moving sequences.

Owner:STMICROELECTRONICS ASIA PACIFIC PTE

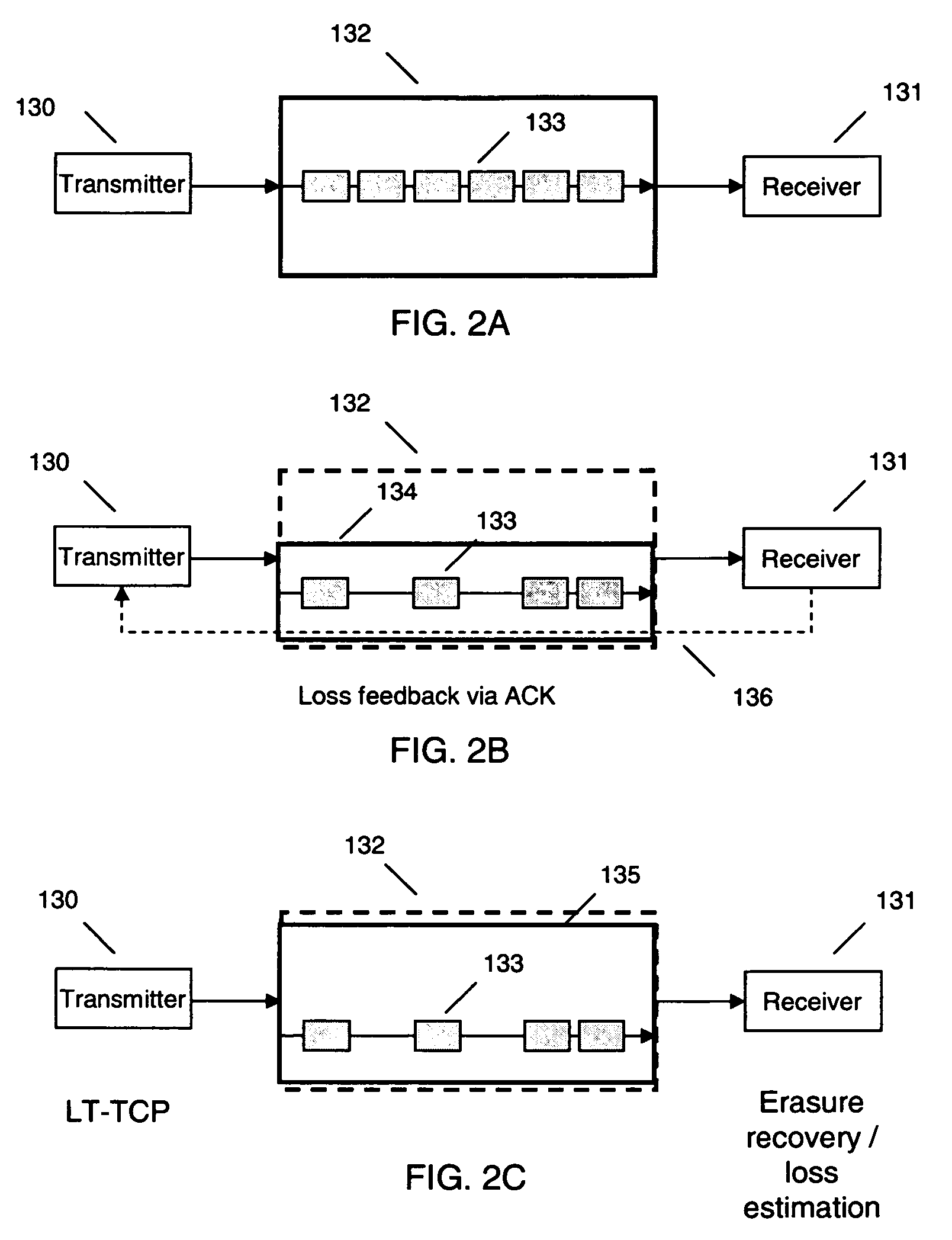

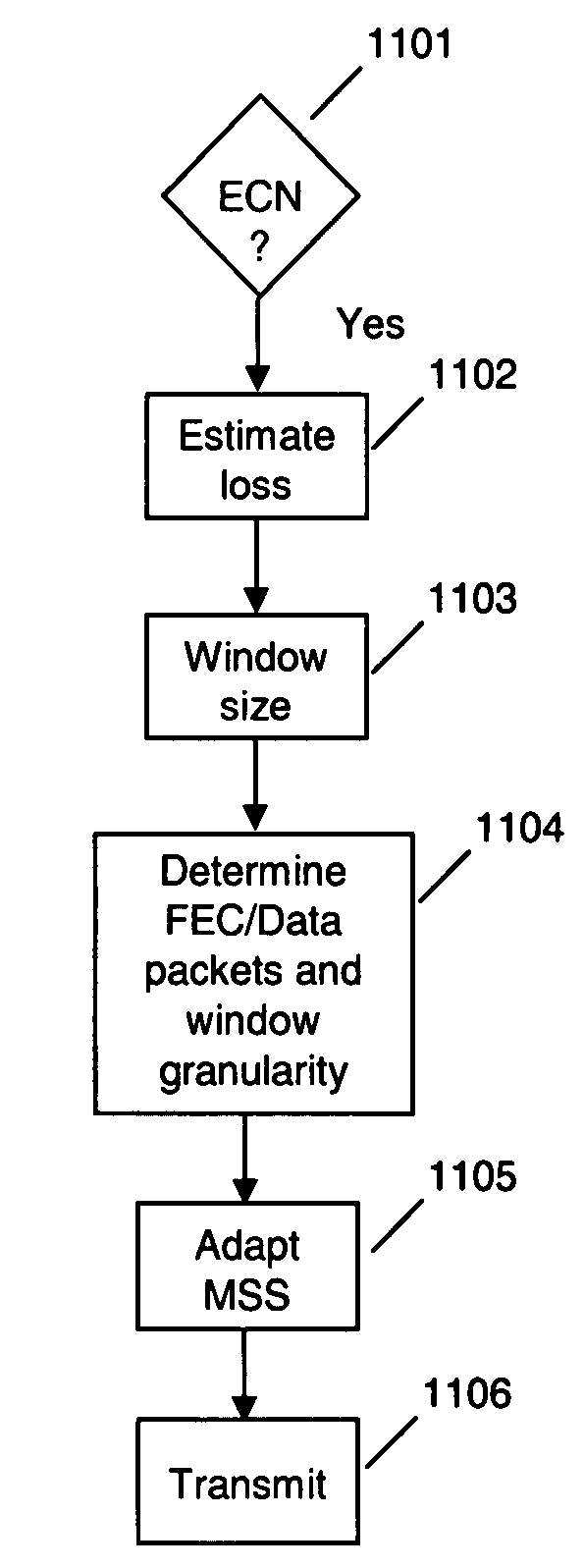

Loss tolerant transmission control protocol

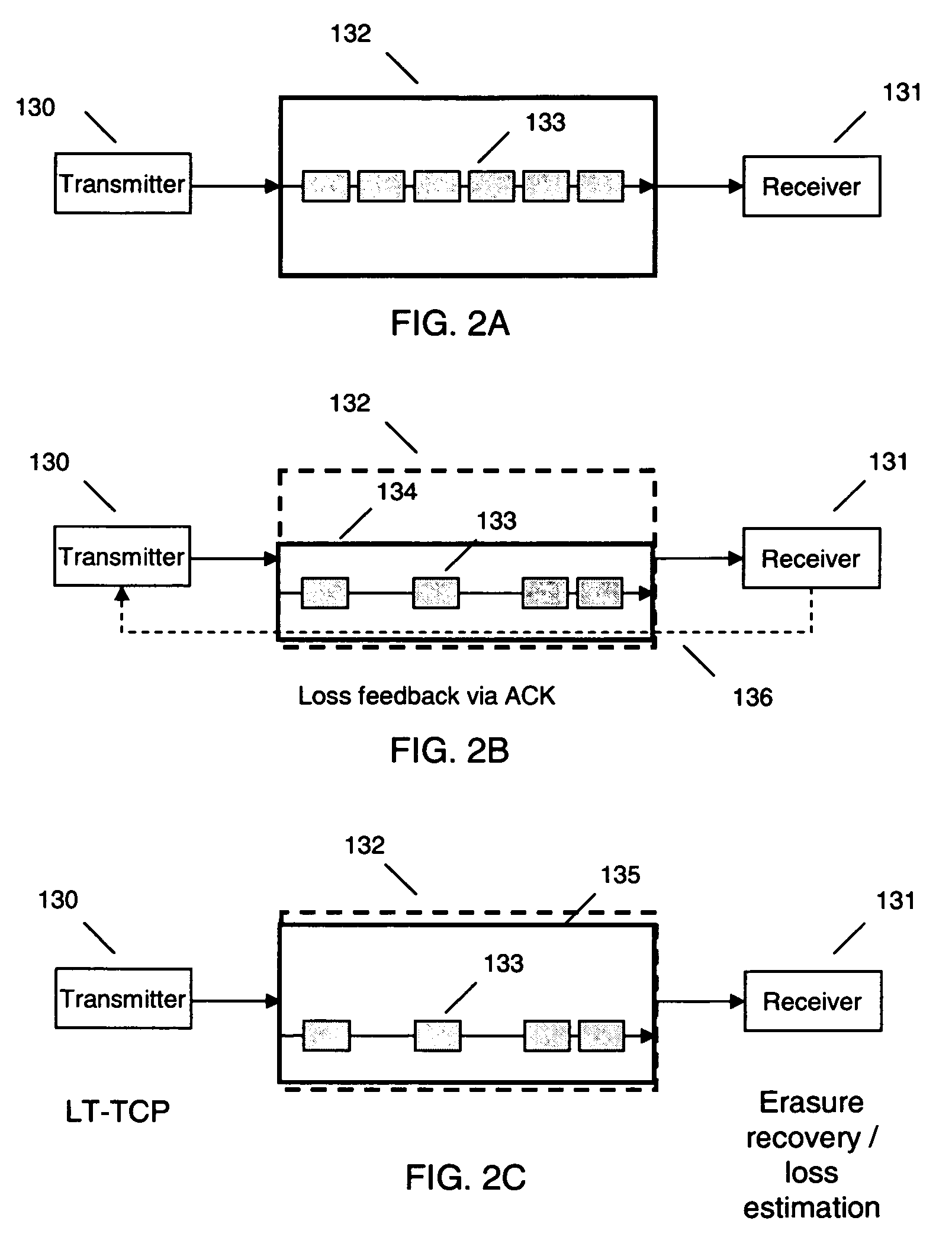

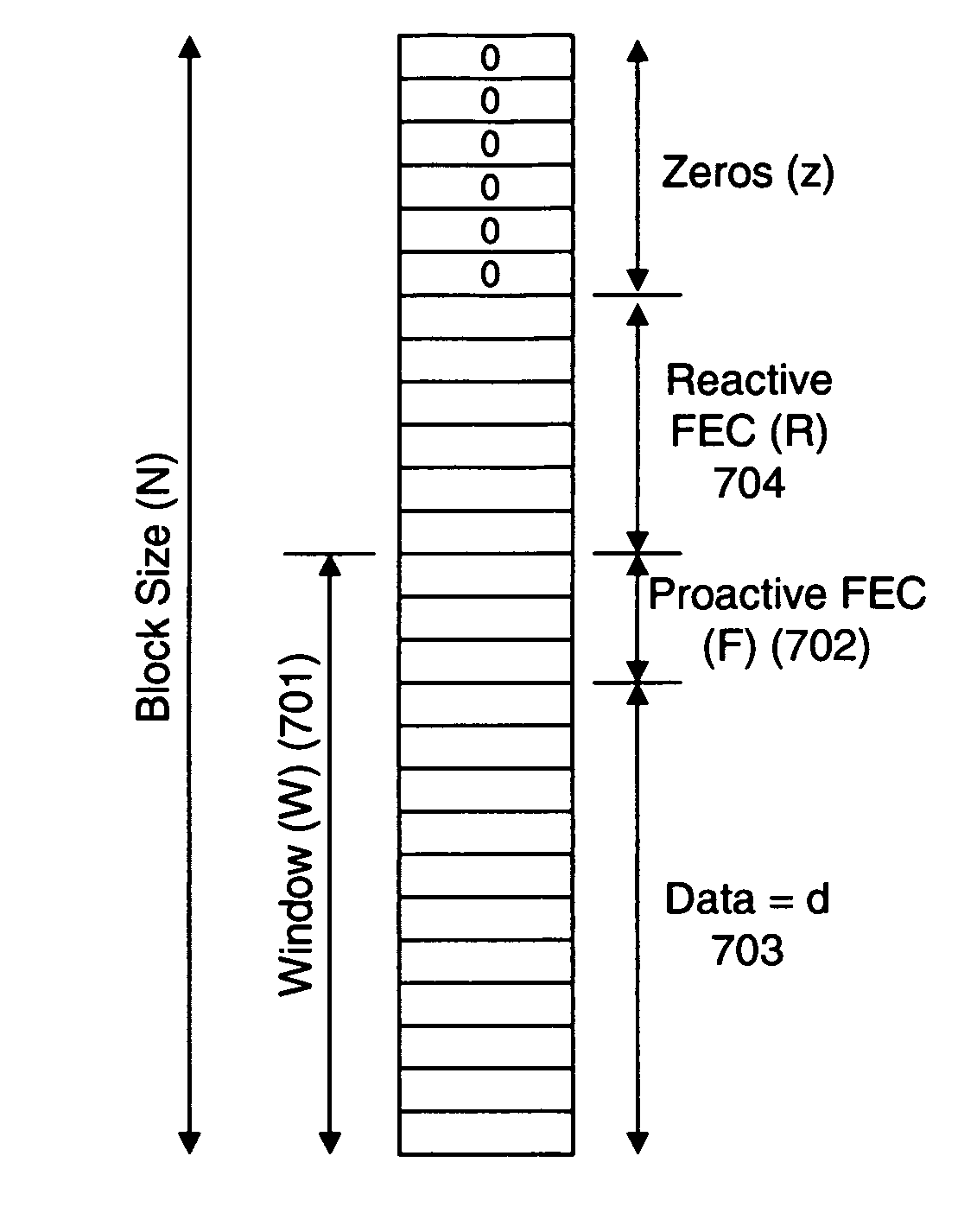

ActiveUS20060251011A1Reduction of congestion windowReduce window sizeTransmission systemsFrequency-division multiplex detailsTransmission protocolCongestion window

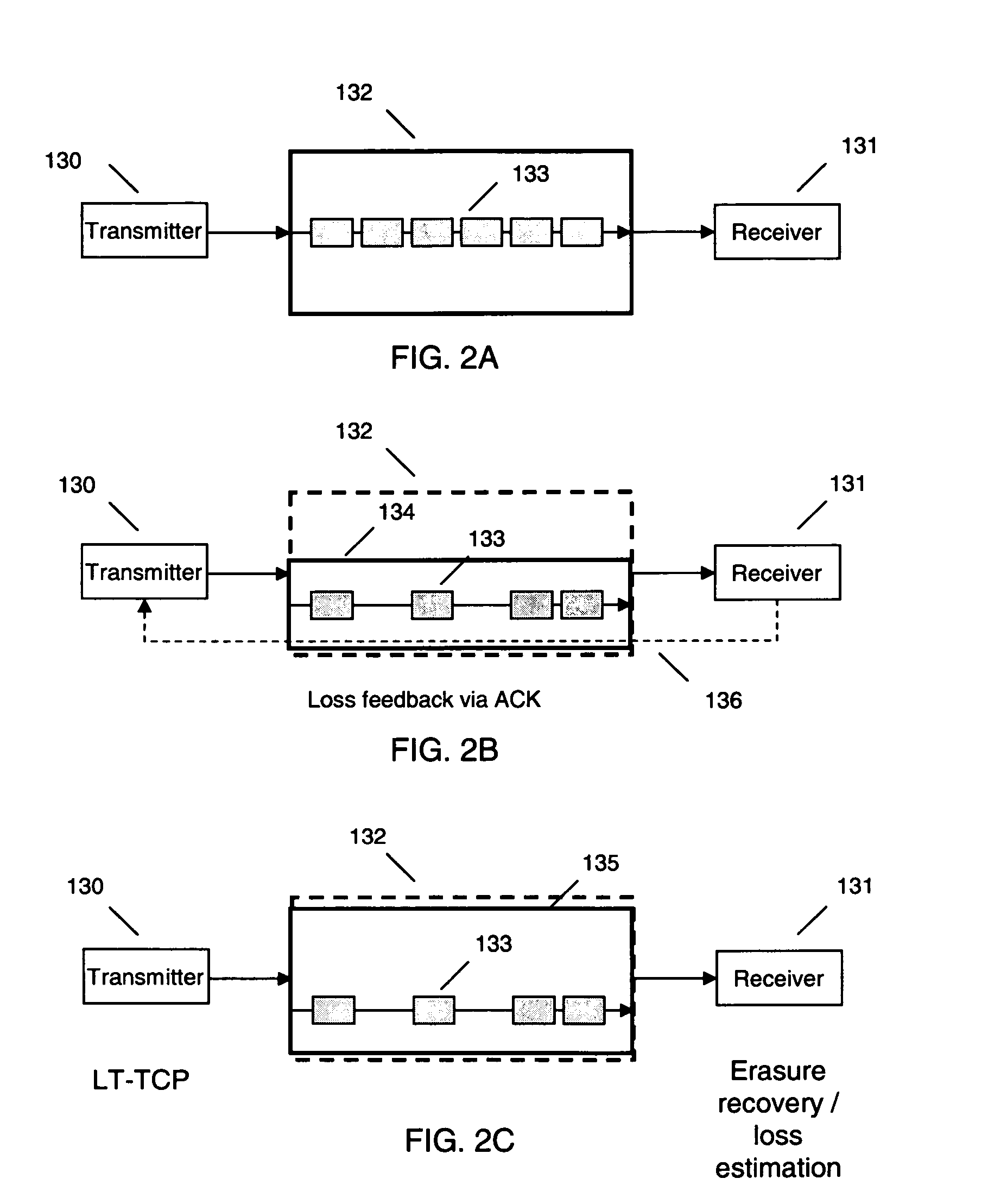

Provided are apparatuses and methods for transmitting or receiving data packets in a data block in a communication network with a transport protocol. In one example, a loss tolerant TCP protocol is used in which a maximum segment size (MSS) may be adapted to a minimum granularity of a congestion window. Also, proactive forward error correction (FEC) packets may be added to a window of the data block. The number of proactive FEC packets may be determined, for example, based on an estimate erasure rate. In addition, reactive FEC packets may be added to the data block. Also, a receiver may receive data packets in a data block and process a selective acknowledgment (SACK) responsive to the data packets received.

Owner:RENESSELAER POLYTECHNIC INST +1

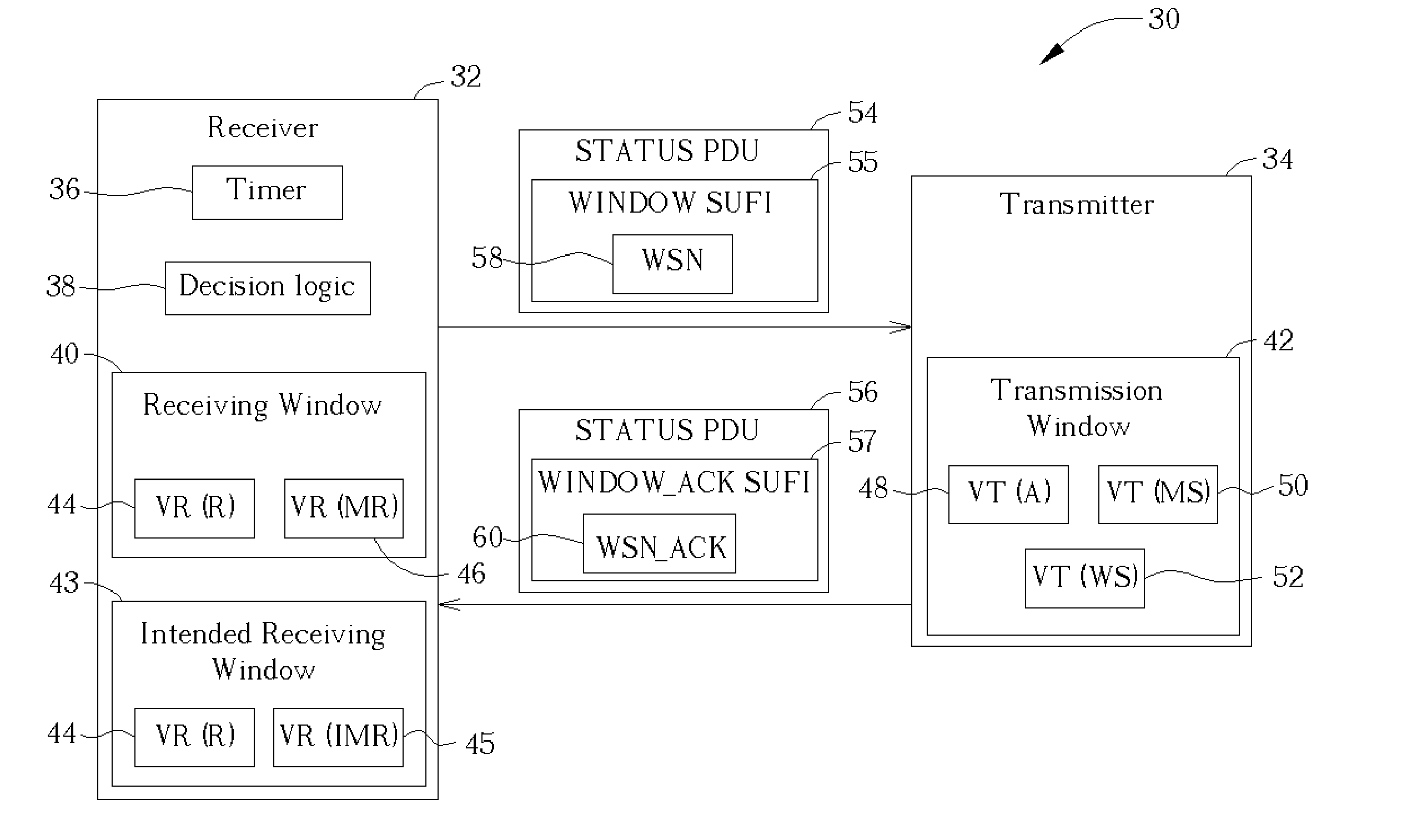

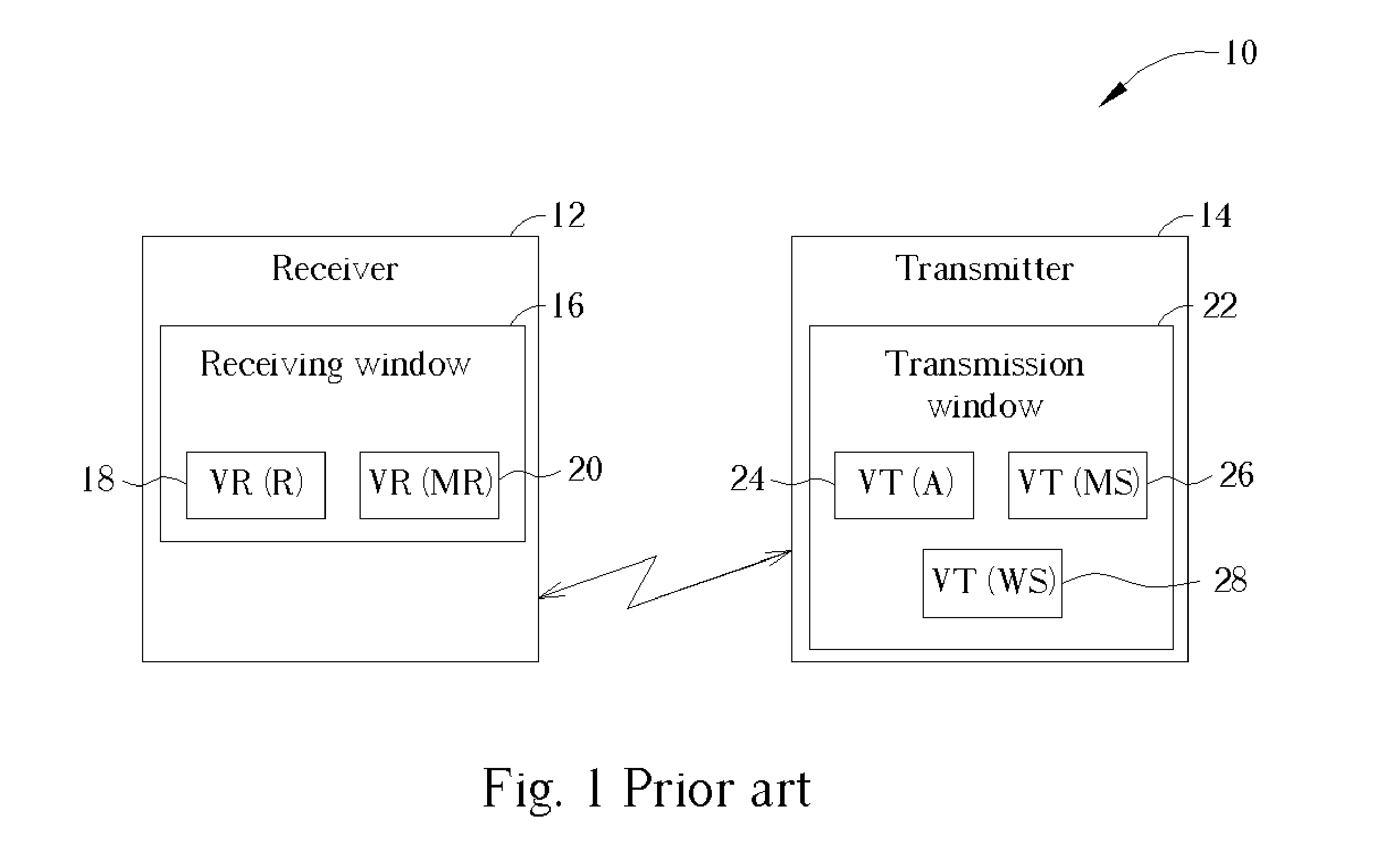

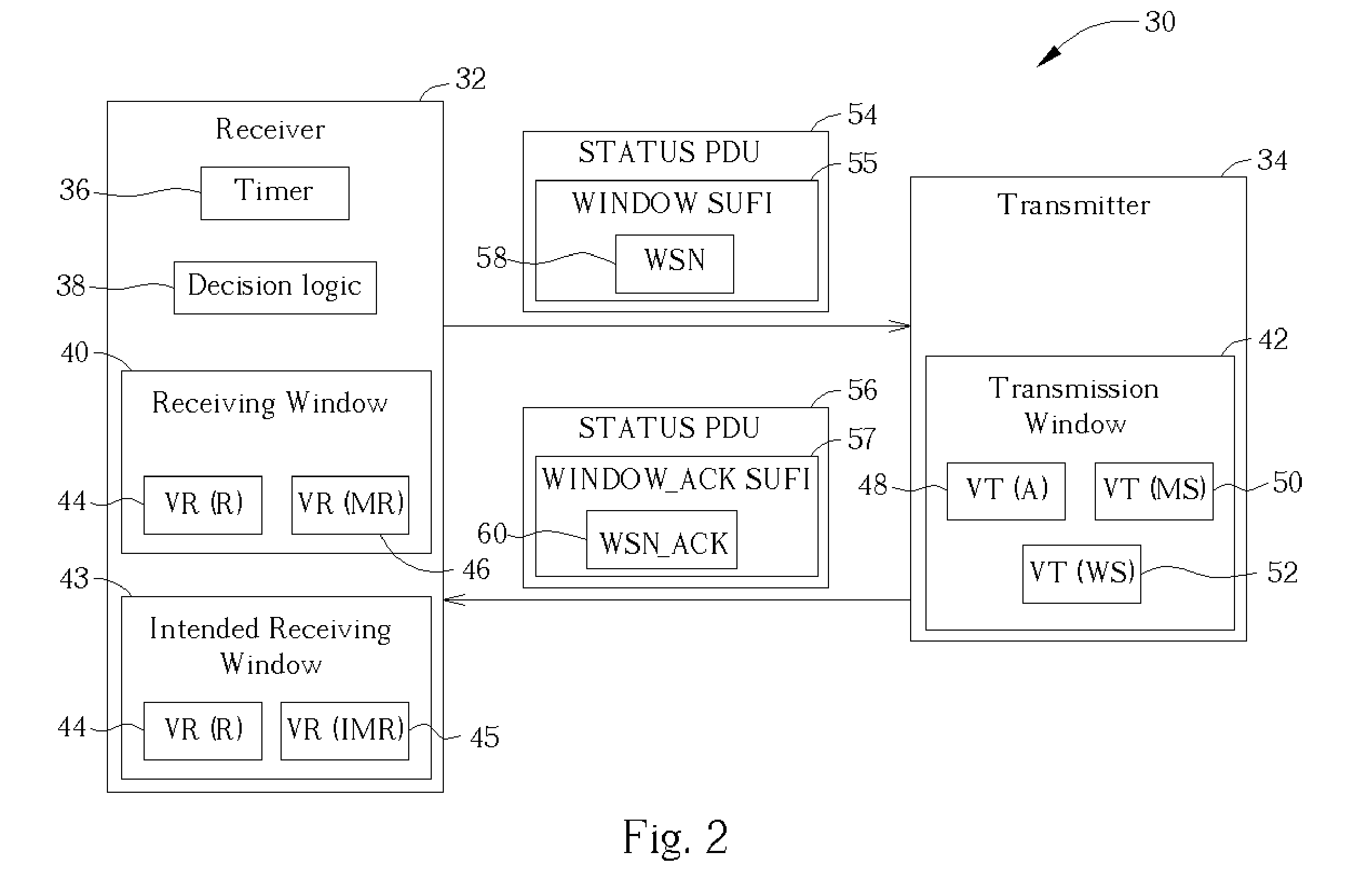

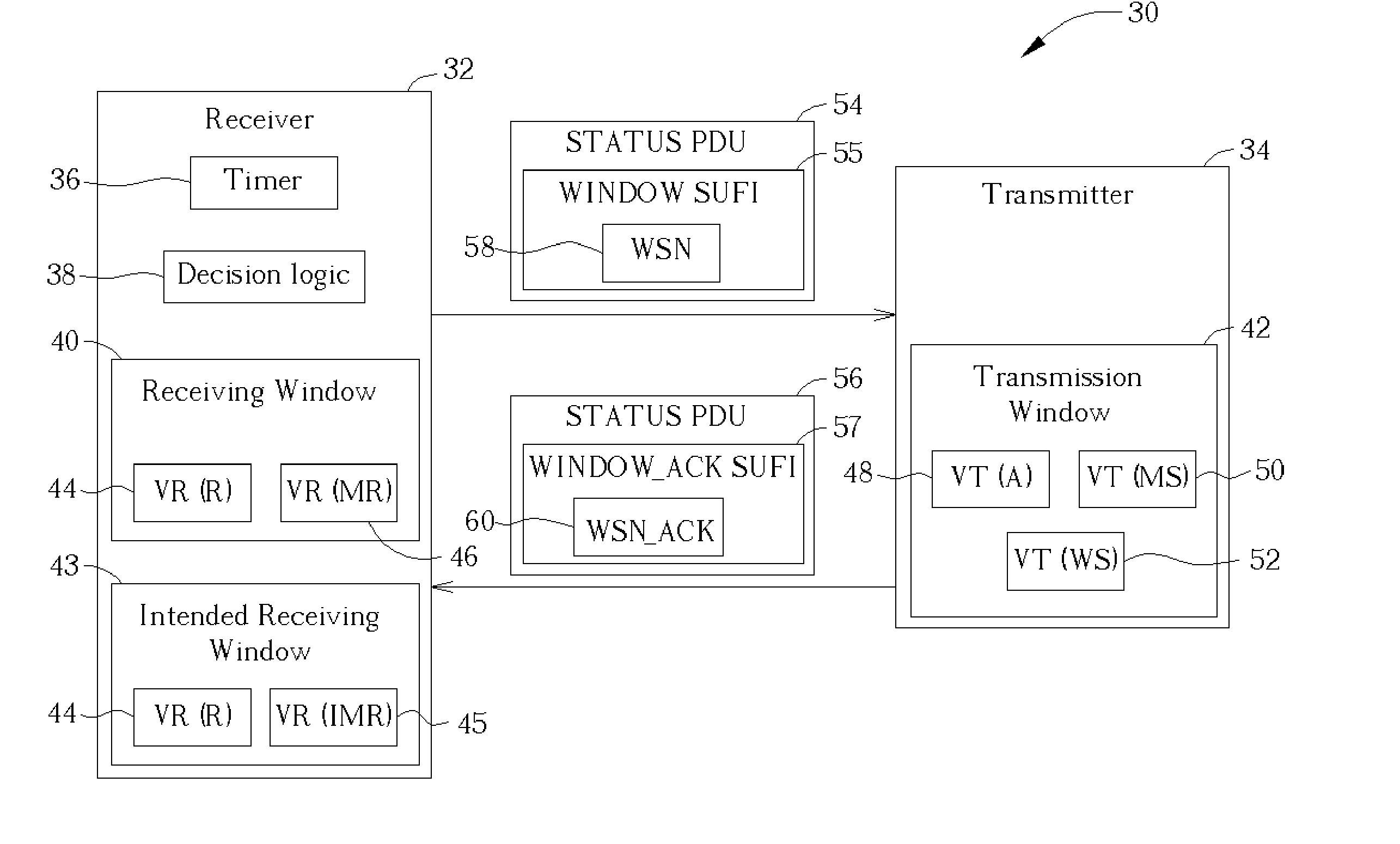

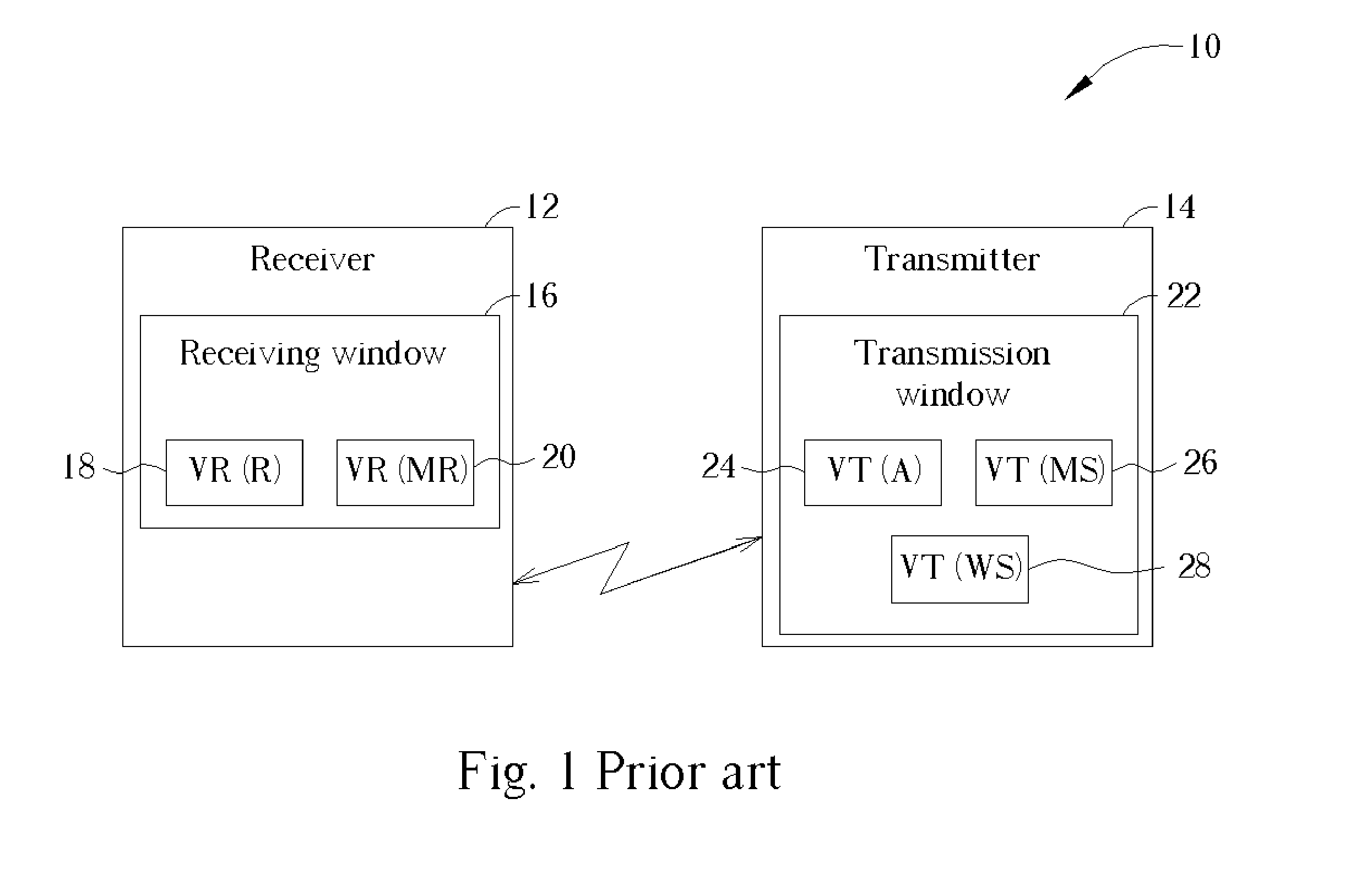

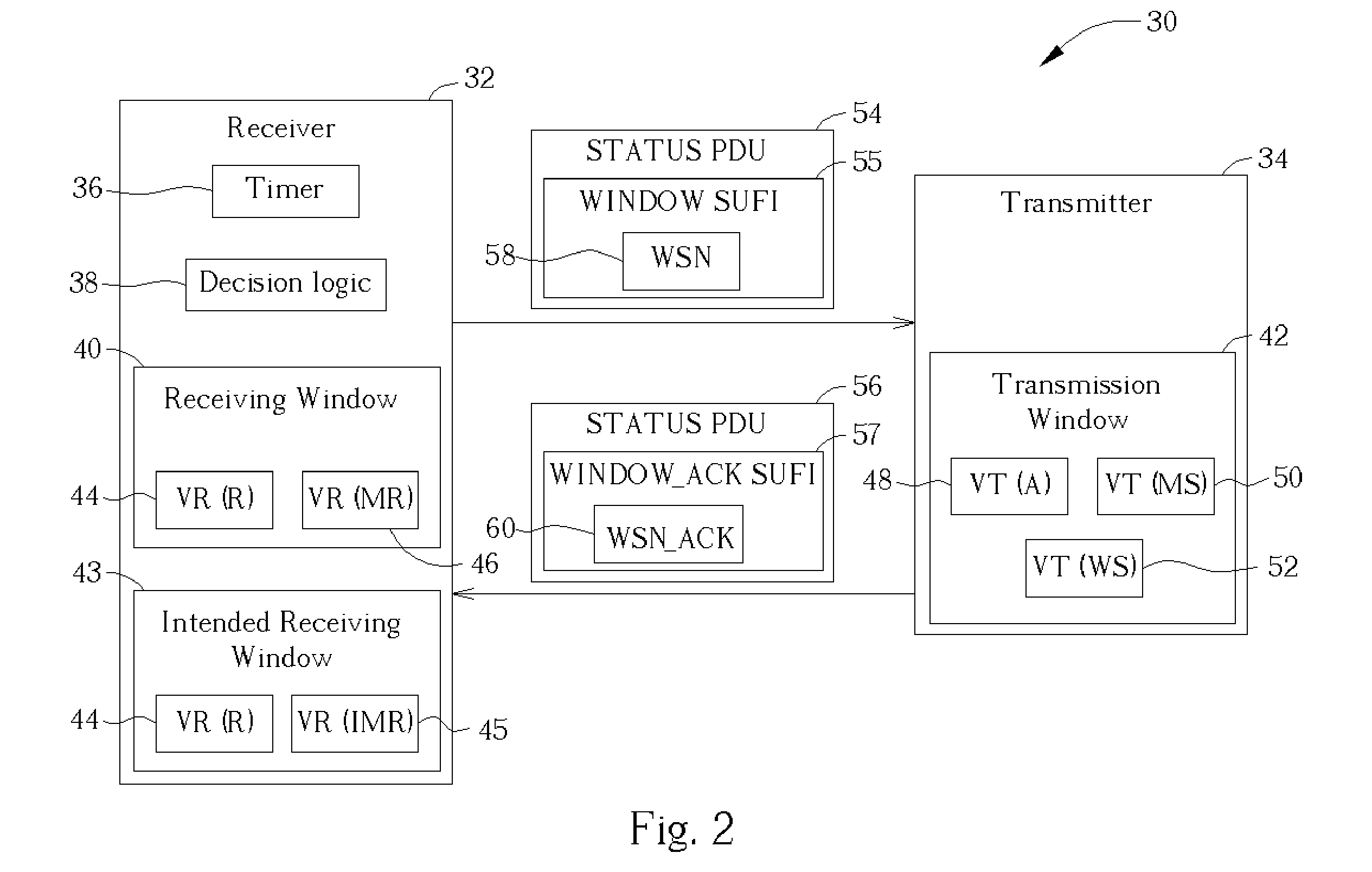

Method of controlling a receiver and a transmitter in a wireless communication system to handle a transmission window size change procedure

InactiveUS20050041586A1Decrease size of transmission windowImproves radio transmission efficiencyError prevention/detection by using return channelFrequency-division multiplex detailsCommunications systemSize change

A method of controlling a receiver and a transmitter to handle a transmission window size change procedure is disclosed. The method includes driving the receiver to deliver a control message having a window size parameter to the transmitter for adjusting a transmission window size of the transmitter, and driving the transmitter to output an acknowledgement message to the re- ceiver and adjust the transmission window size according to the window size parameter when the transmitter receives the control message.

Owner:INNOVATIVE SONIC

Interactive presentation viewing system employing multi-media components

InactiveUS20060288389A1Increase or decrease sizeReduce window sizeTelevision system detailsAnalogue secracy/subscription systemsGraphicsGraphical user interface

An interactive, multi-media presentation viewing system and process for viewing educational or business presentations integrating presentation graphics in the form of presentation slides, video, audio, text, and other streaming media into a powerfully coordinated viewing experience for the end user. The viewing system is an aggregate of synchronized presentation graphics, video, and text displays employing a graphical user interface that allows the user to control all aspects of media playback.

Owner:MICROSOFT TECH LICENSING LLC

Loss tolerant transmission control protocol

ActiveUS7889654B2Reduce congestionReduce window sizeFrequency-division multiplex detailsNetwork traffic/resource managementCongestion windowTransmission protocol

Owner:RENESSELAER POLYTECHNIC INST +1

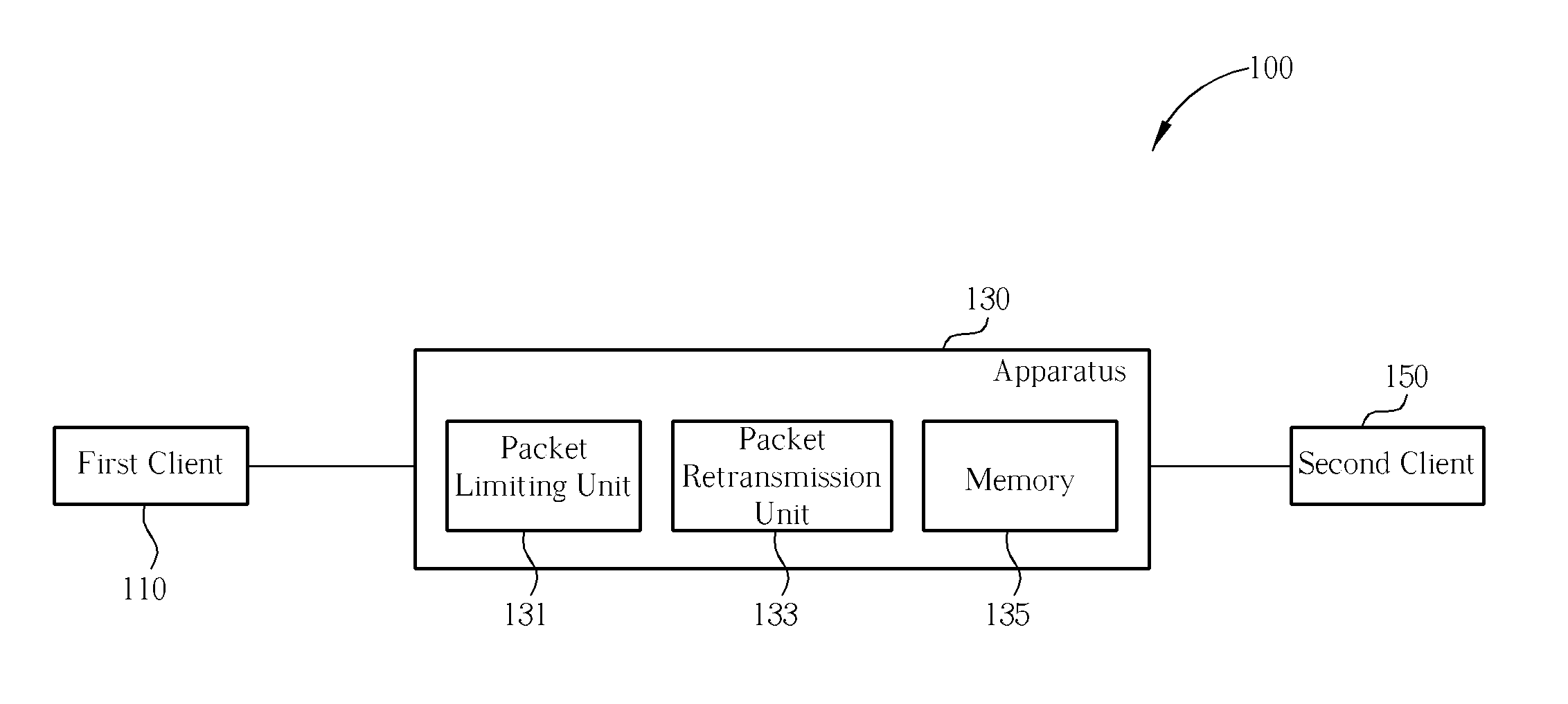

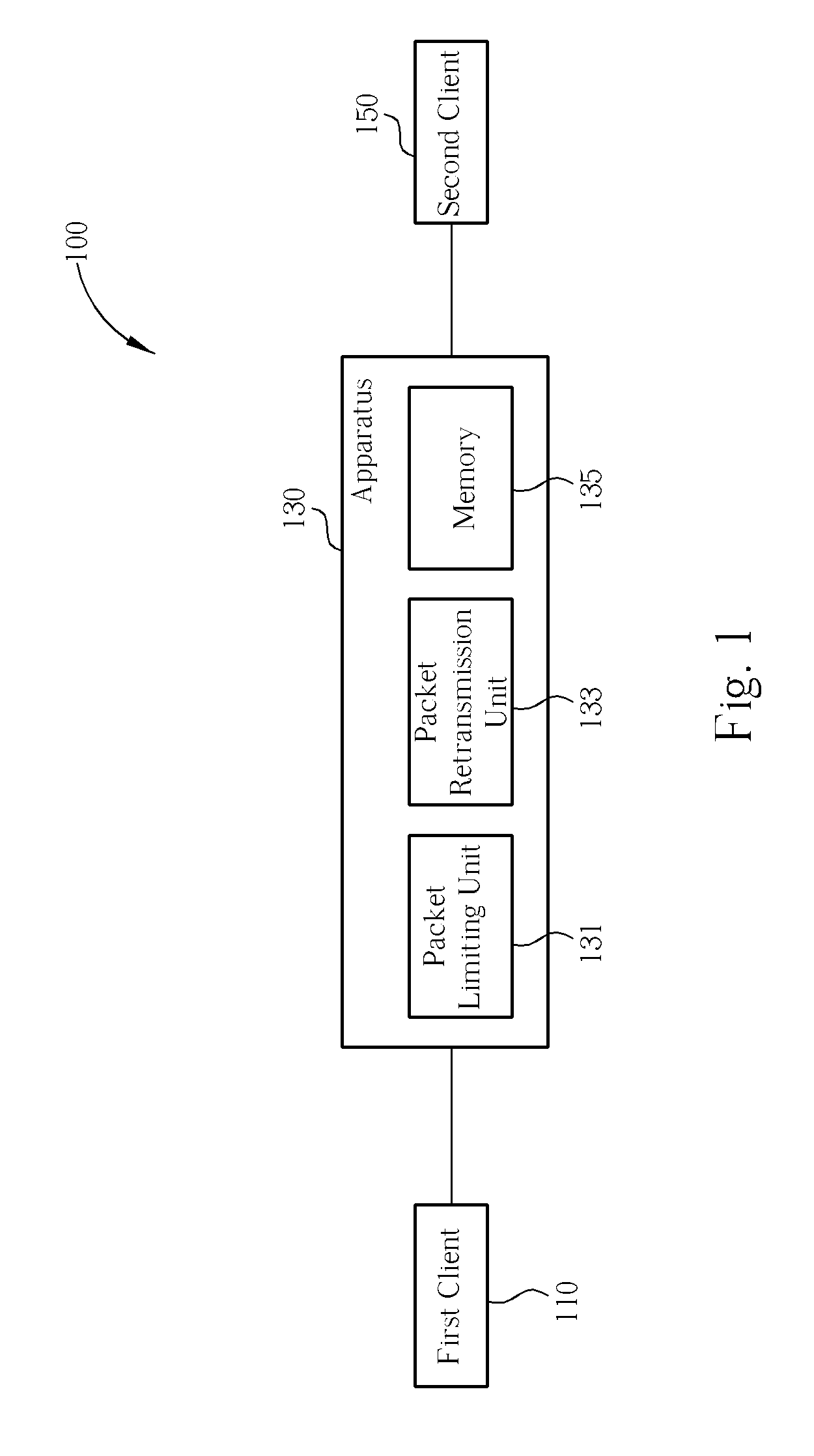

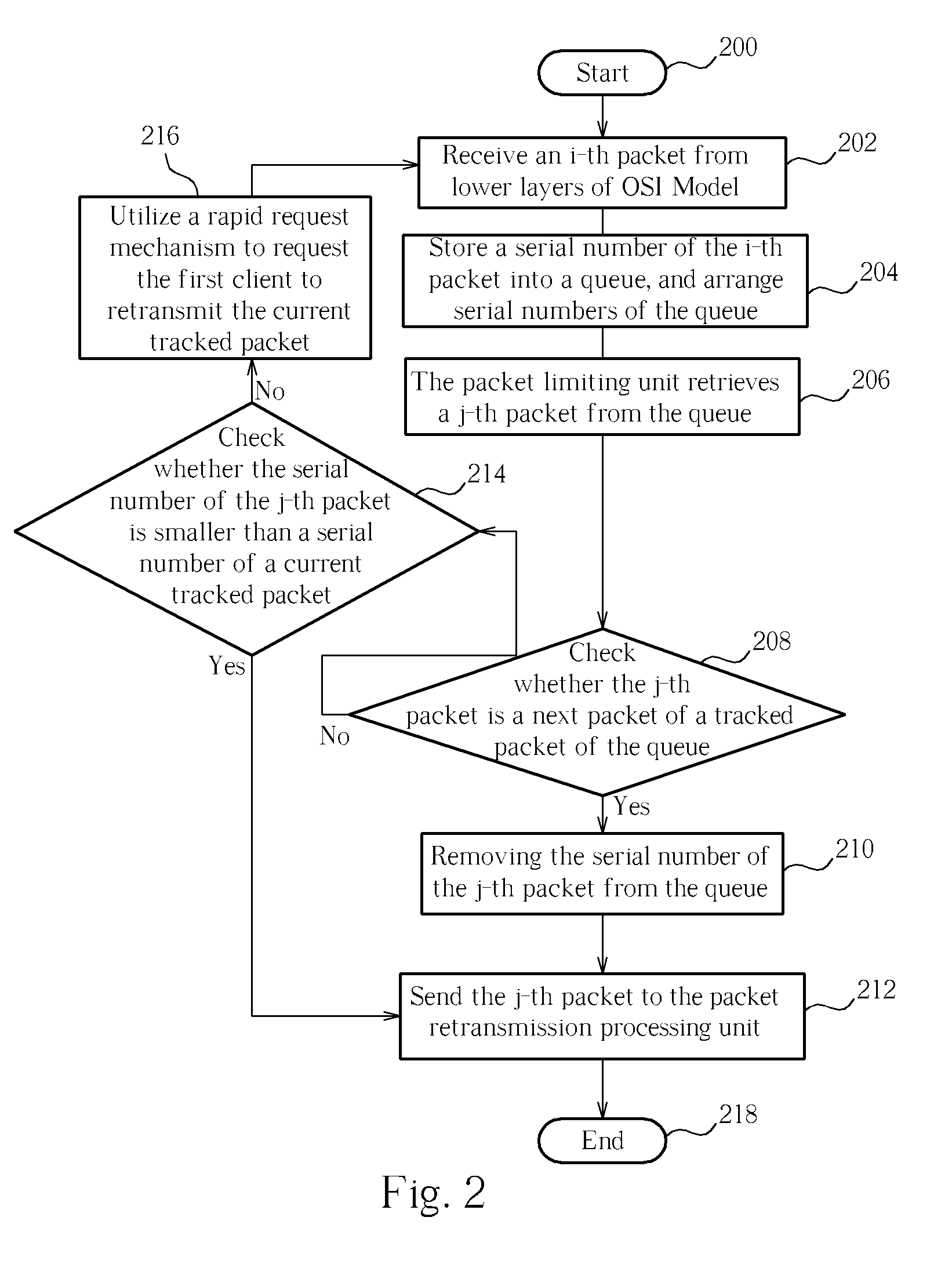

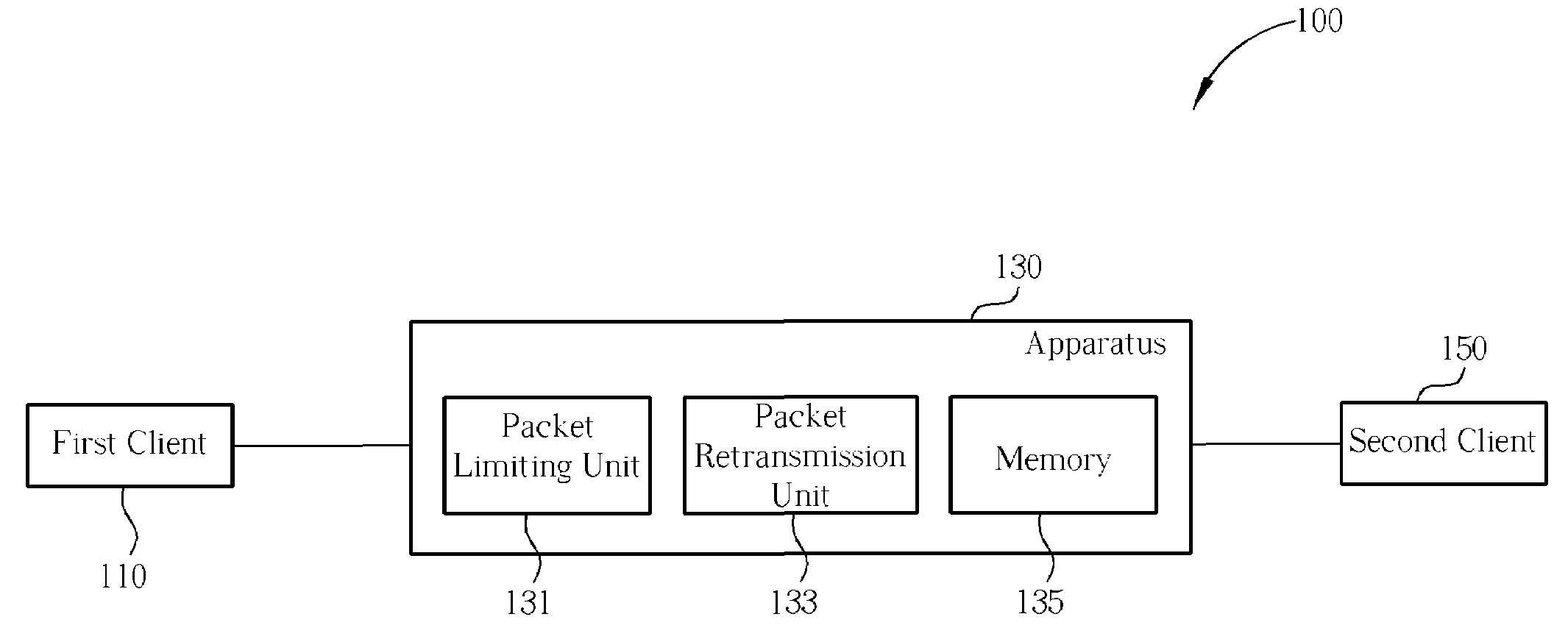

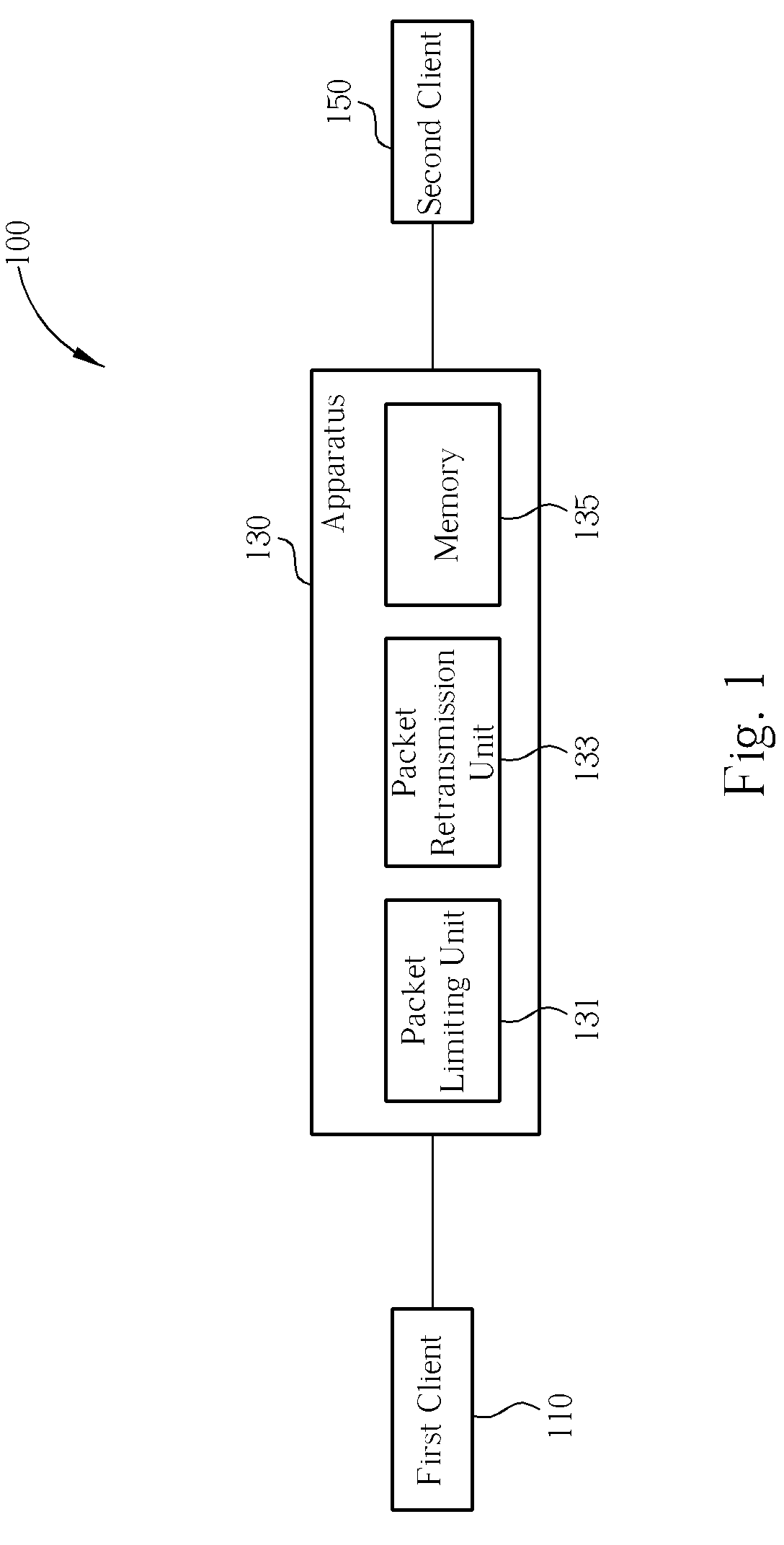

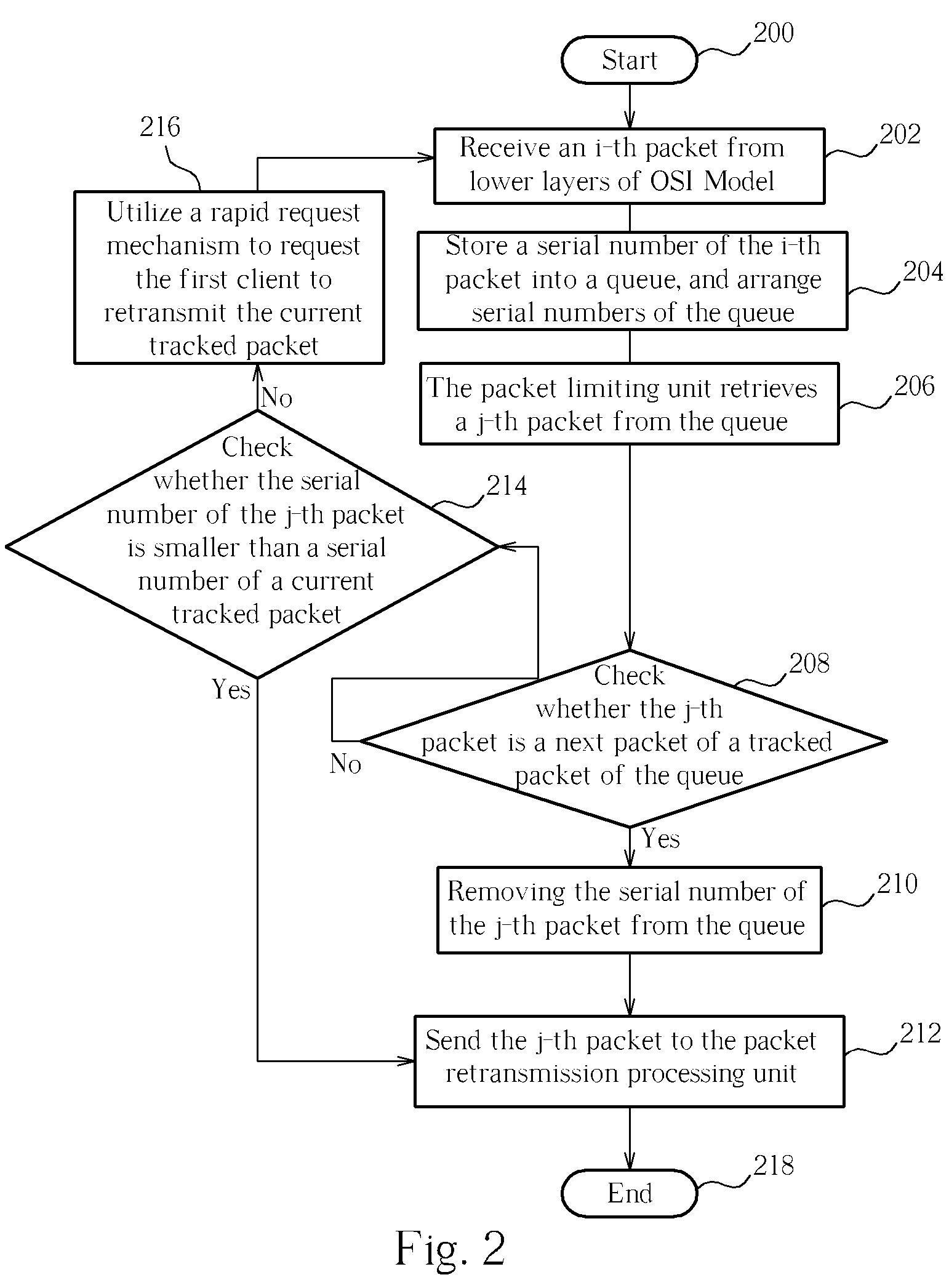

Network Flow/Stream Simulation Method

InactiveUS20070097982A1Reduce window sizeError preventionData switching by path configurationLinked listReal-time computing

Before packets enter a router, a packing limiting unit abandons out-of-order packets, decreases a window size, and stores temperately part of said out-of-order packets for having packets pass the packet limiting unit with a better efficiency and a precise order. After packets enter said router, a packet retransmission processing unit acquires a characteristic values and messages calculated from each characteristic value of a packet for obtaining the order, size, header, and check bits for assisting in identifying packets, and stores the characteristic values with a link list for saving memory utility. With both the abovementioned methods, problems of out-or-order and retransmission during packets are transmitted, and of an over-used amount of memory, are solved.

Owner:DRAYTEK

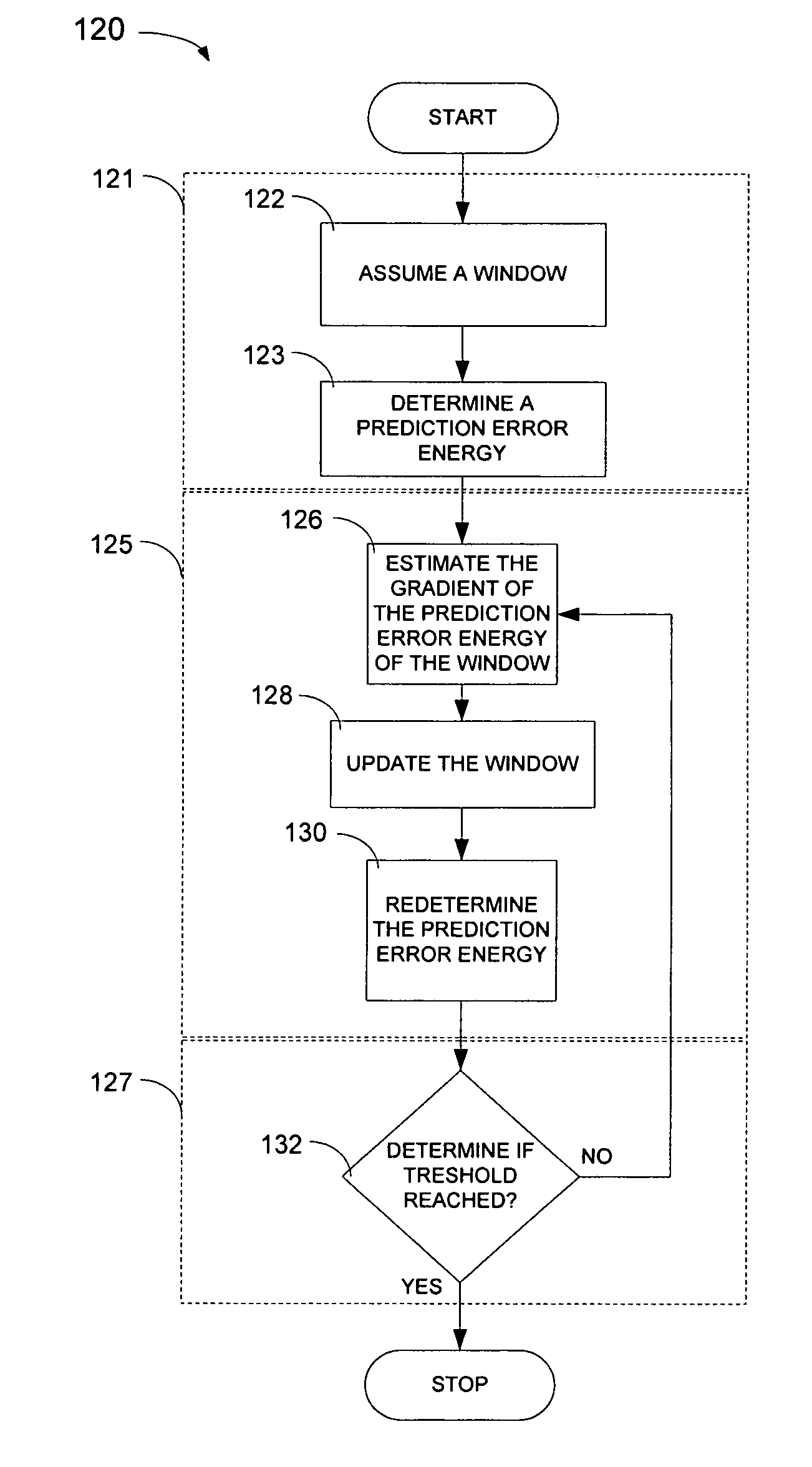

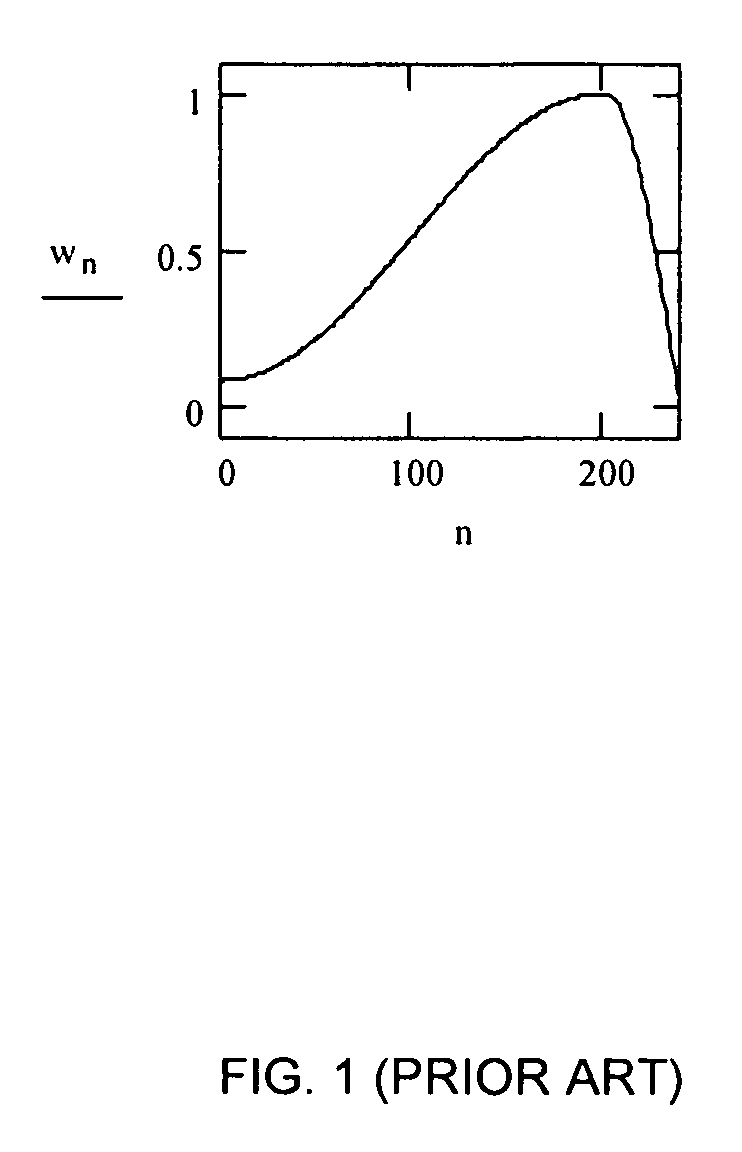

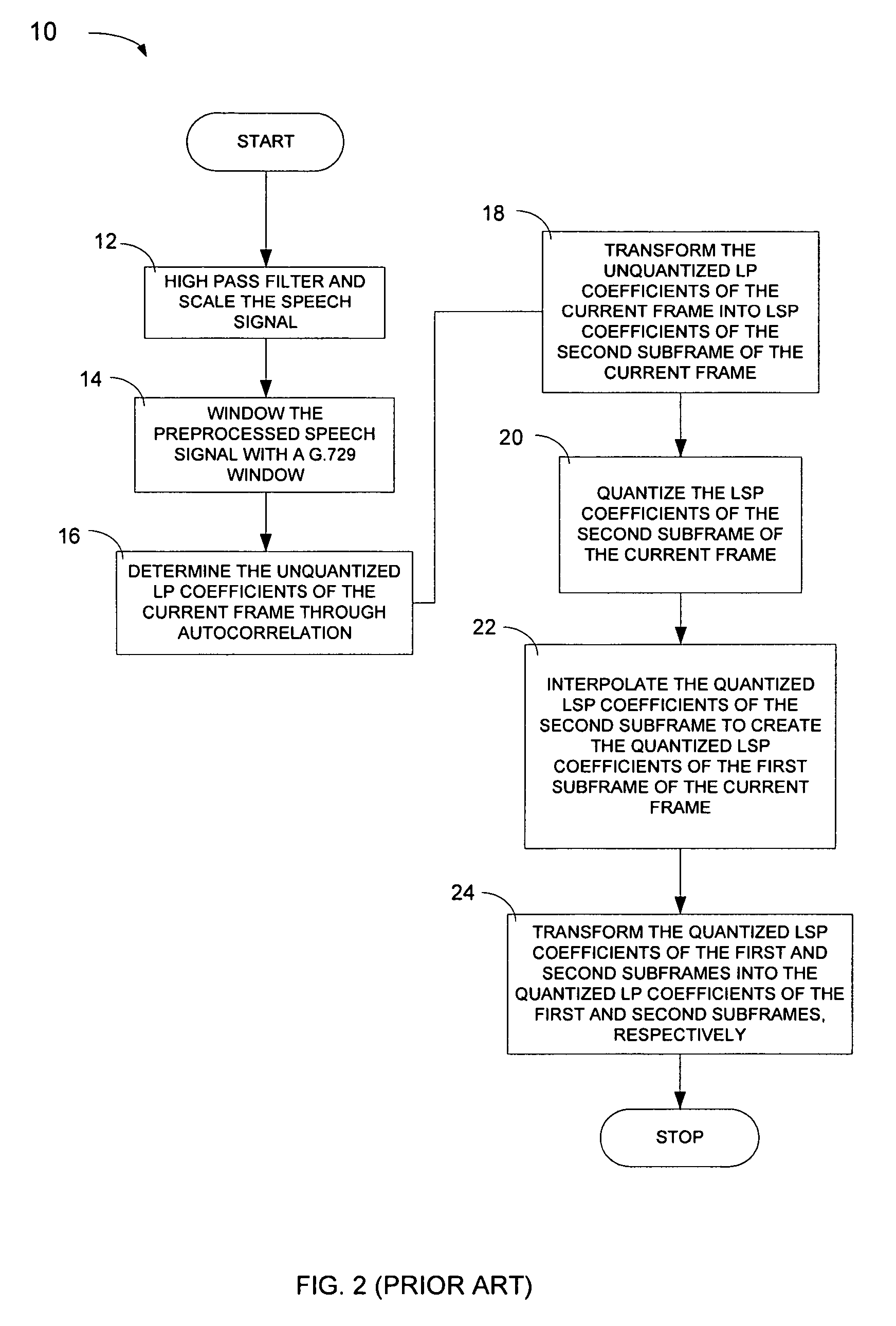

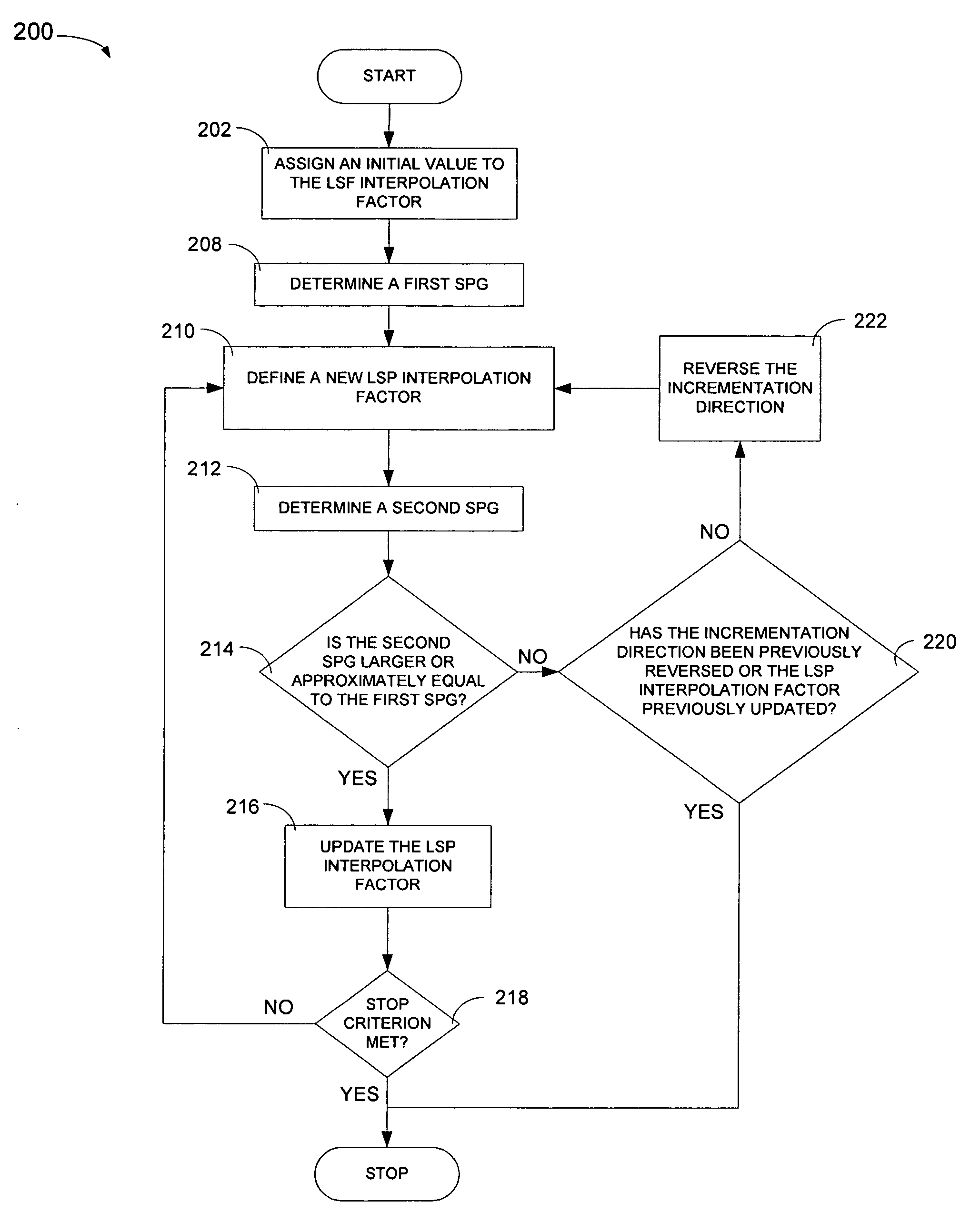

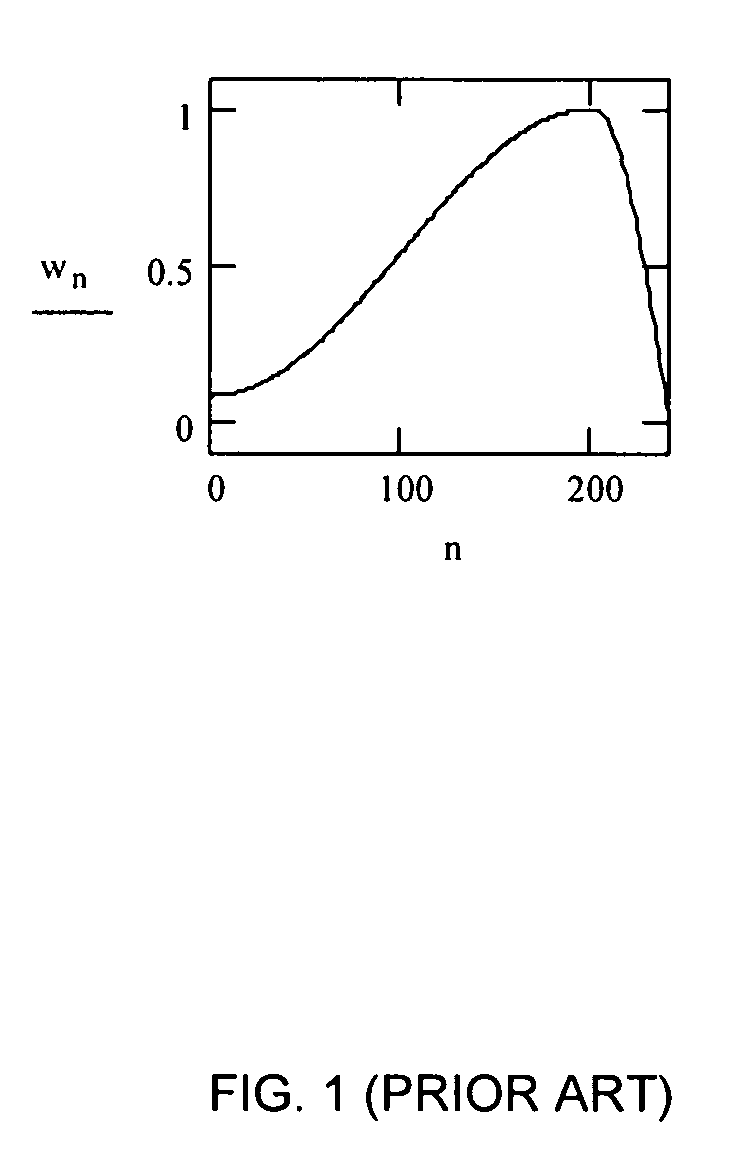

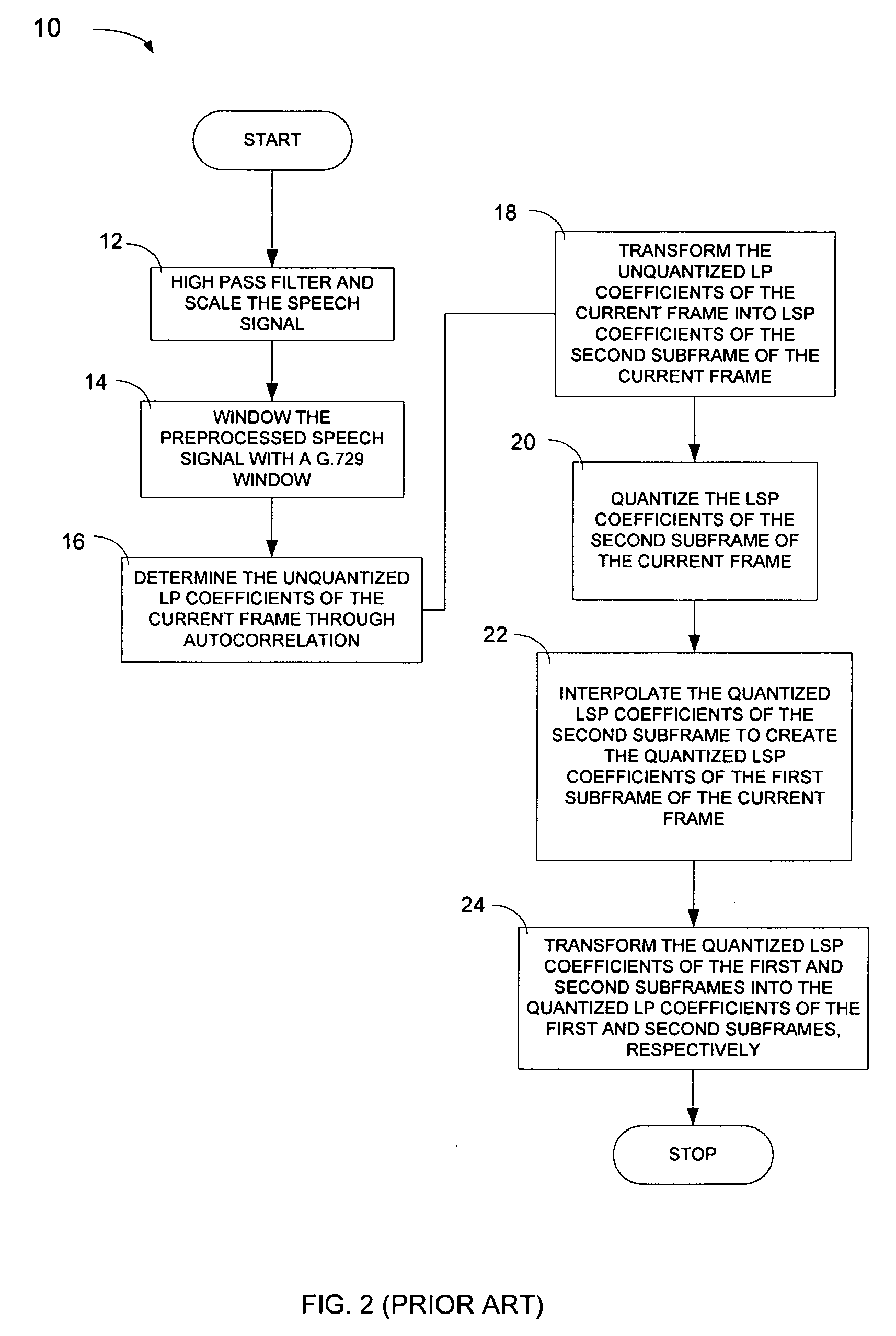

Optimized windows and interpolation factors, and methods for optimizing windows, interpolation factors and linear prediction analysis in the ITU-T G.729 speech coding standard

InactiveUS20070055503A1Reduce window sizeFuture buffering requirementSpeech analysisLinear predictionSoftware

Alternate window optimization procedures and / or LSP interpolation factor optimization procedures are used to improve the ITU-T G.729 speech coding standard (the “Standard”) by replacing the window used by the Standard with an optimized window and / or replacing the LSP interpolation factor used by the standard with an optimized LSP interpoltion factor. Optimized windows created using the alternate window optimization procedure and / or optimized LSP interpolation factors created using the LSP interpolation factor optimization procedure yield improvements in the objective quality of synthesized speech produced by the Standard. In many cases, improvements are obtained using shorter windows, which results in reduced computational cost and / or smaller future buffering requirements, which results in lowered coding delay. The improved Standard, procedures, and optimized windows and LSP interpolation factors can all be implemented as computer readable software code and in optimization devices.

Owner:DOCOMO COMMUNICATIONS LABORATORIES USA INC

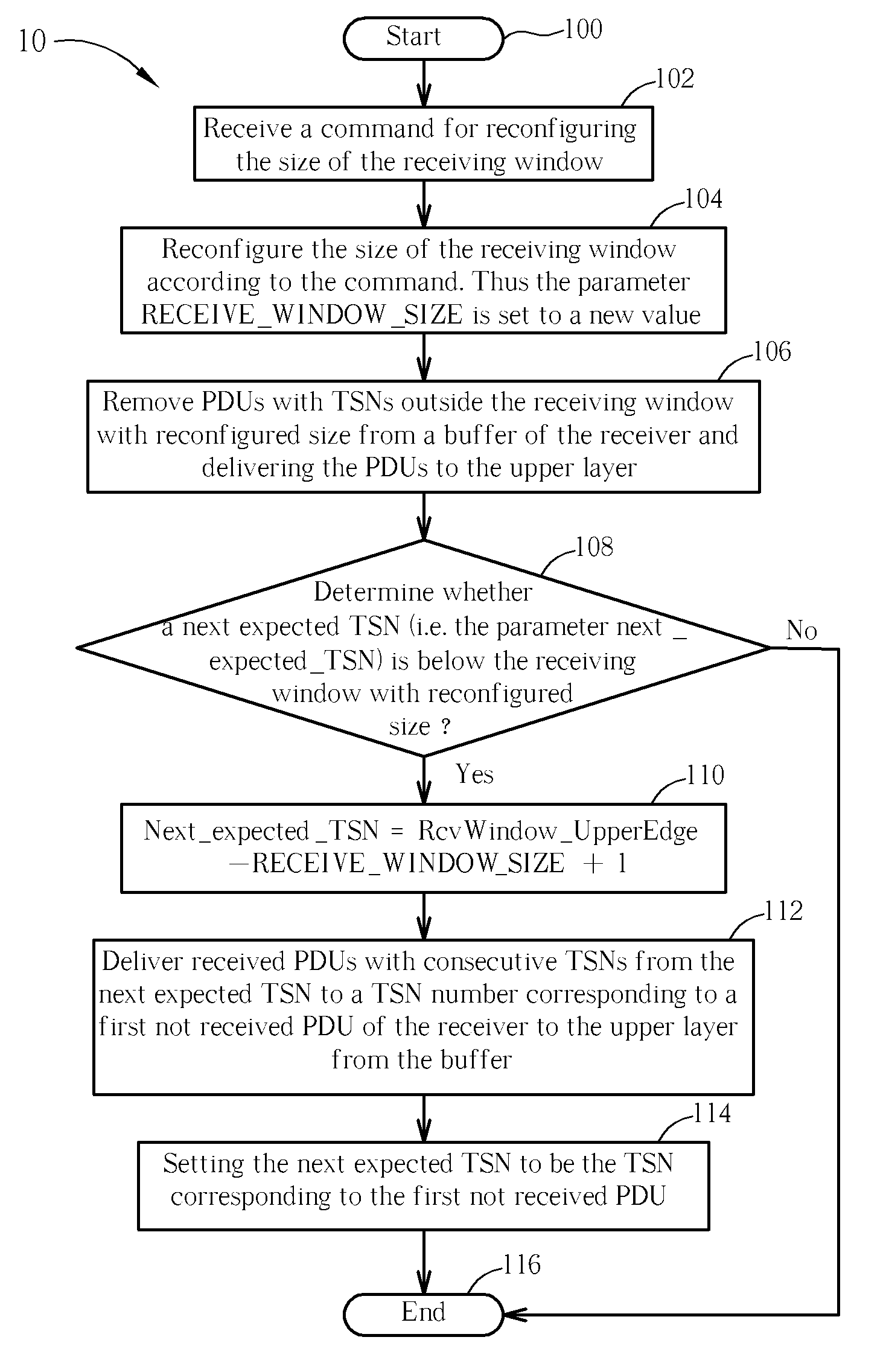

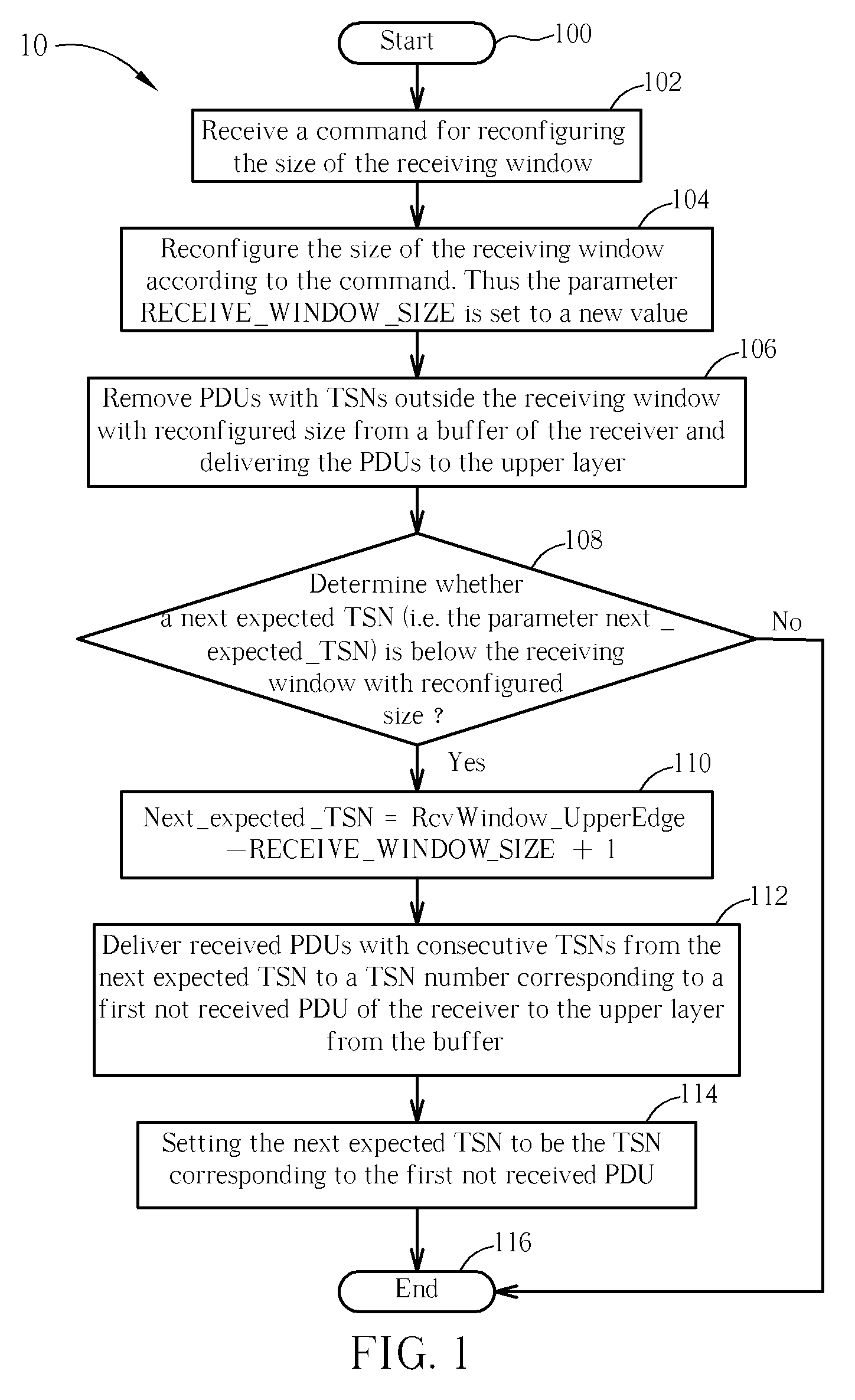

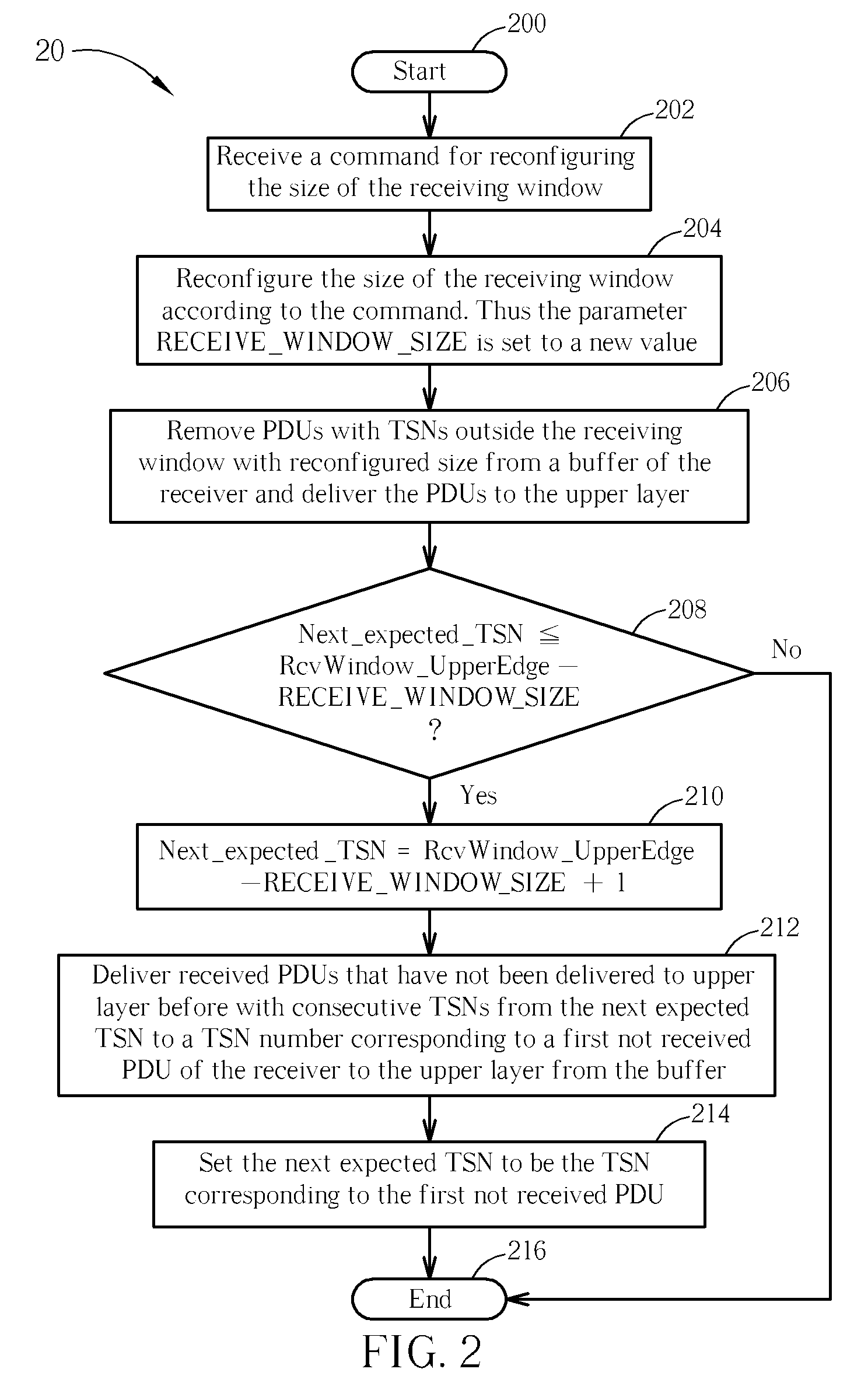

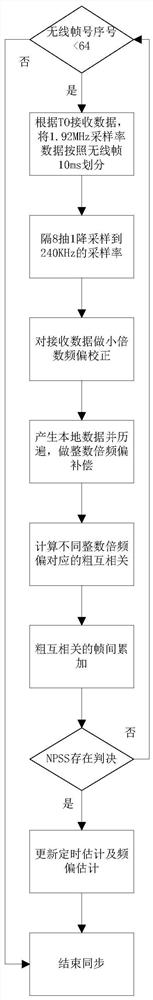

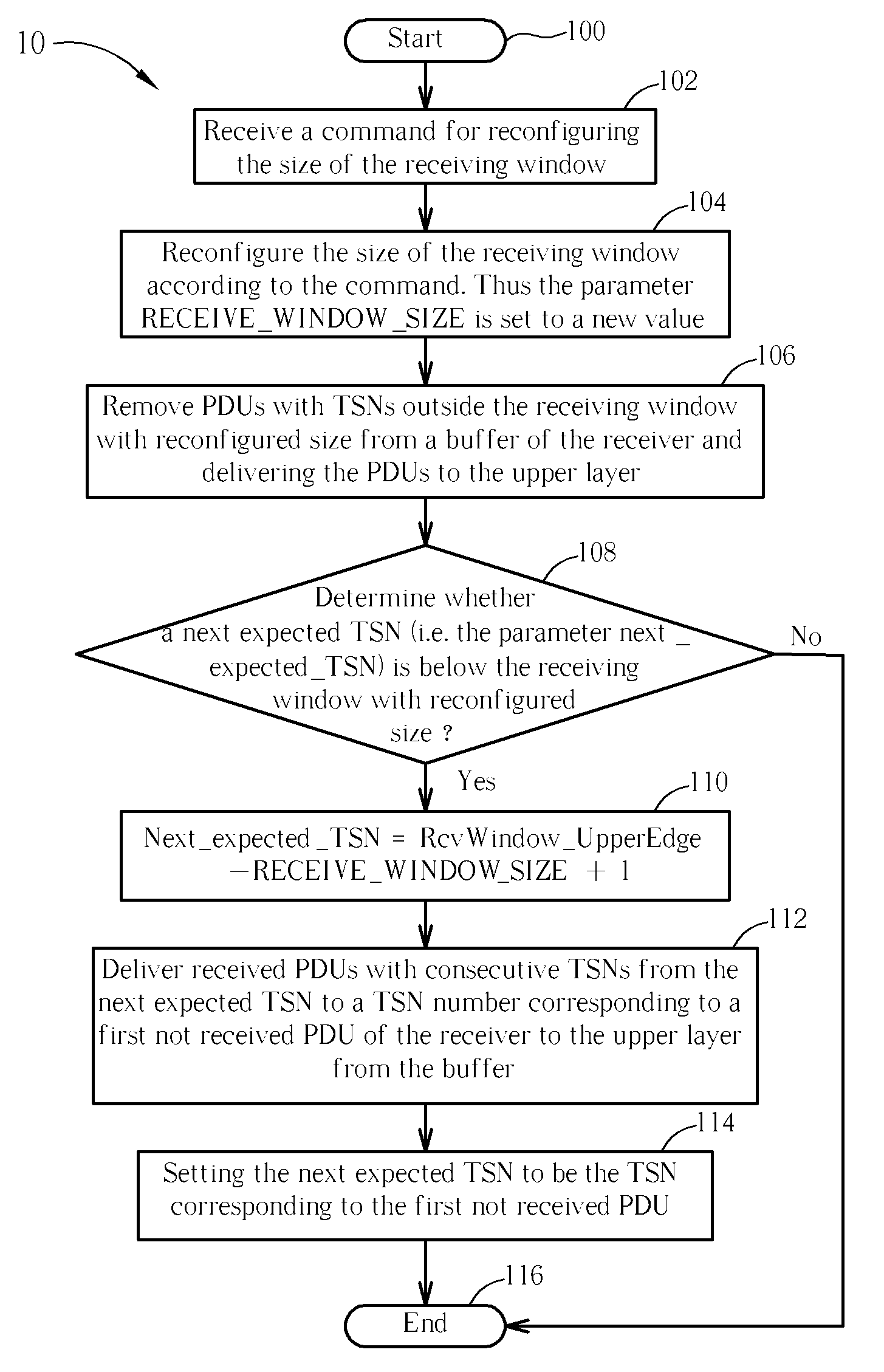

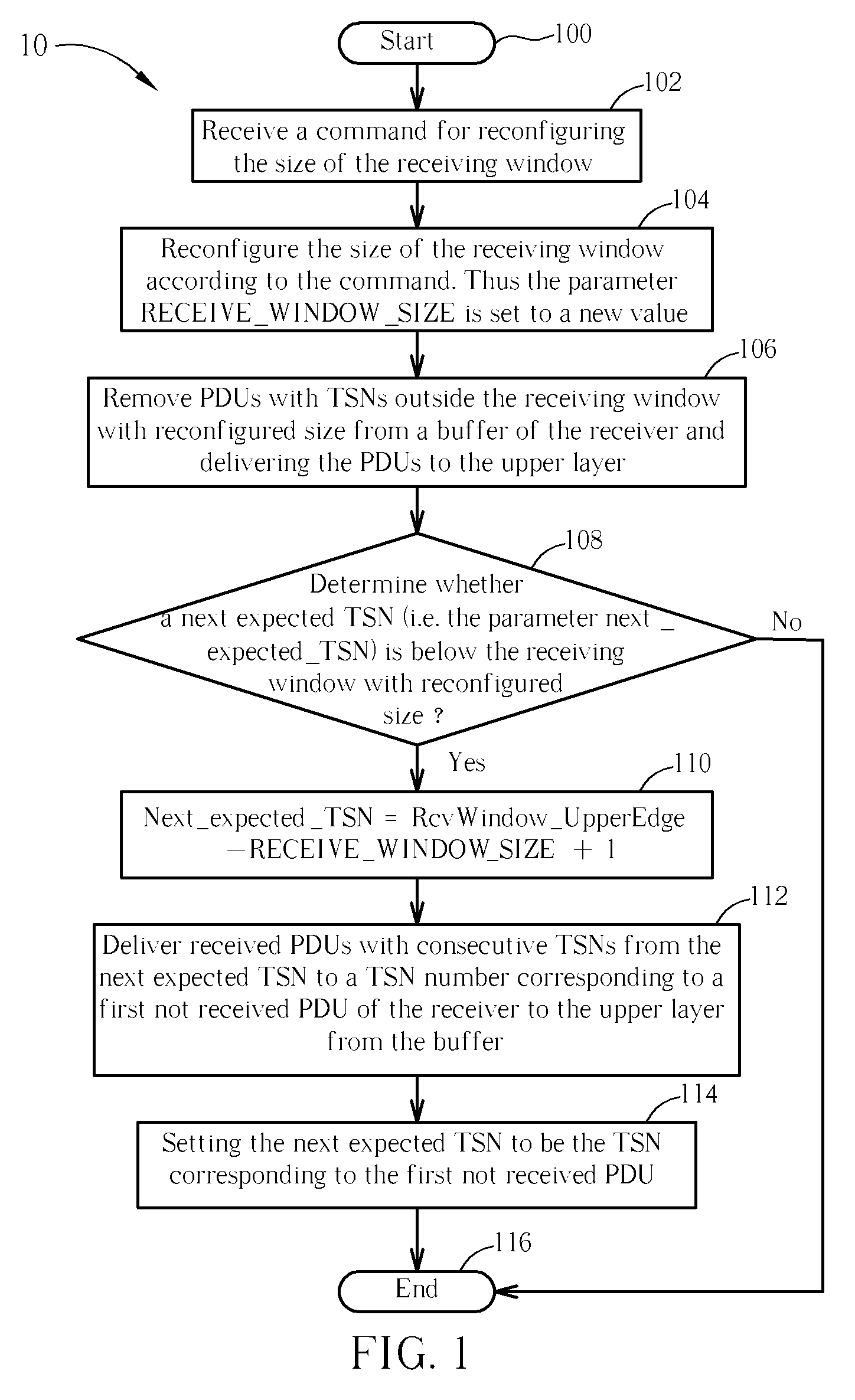

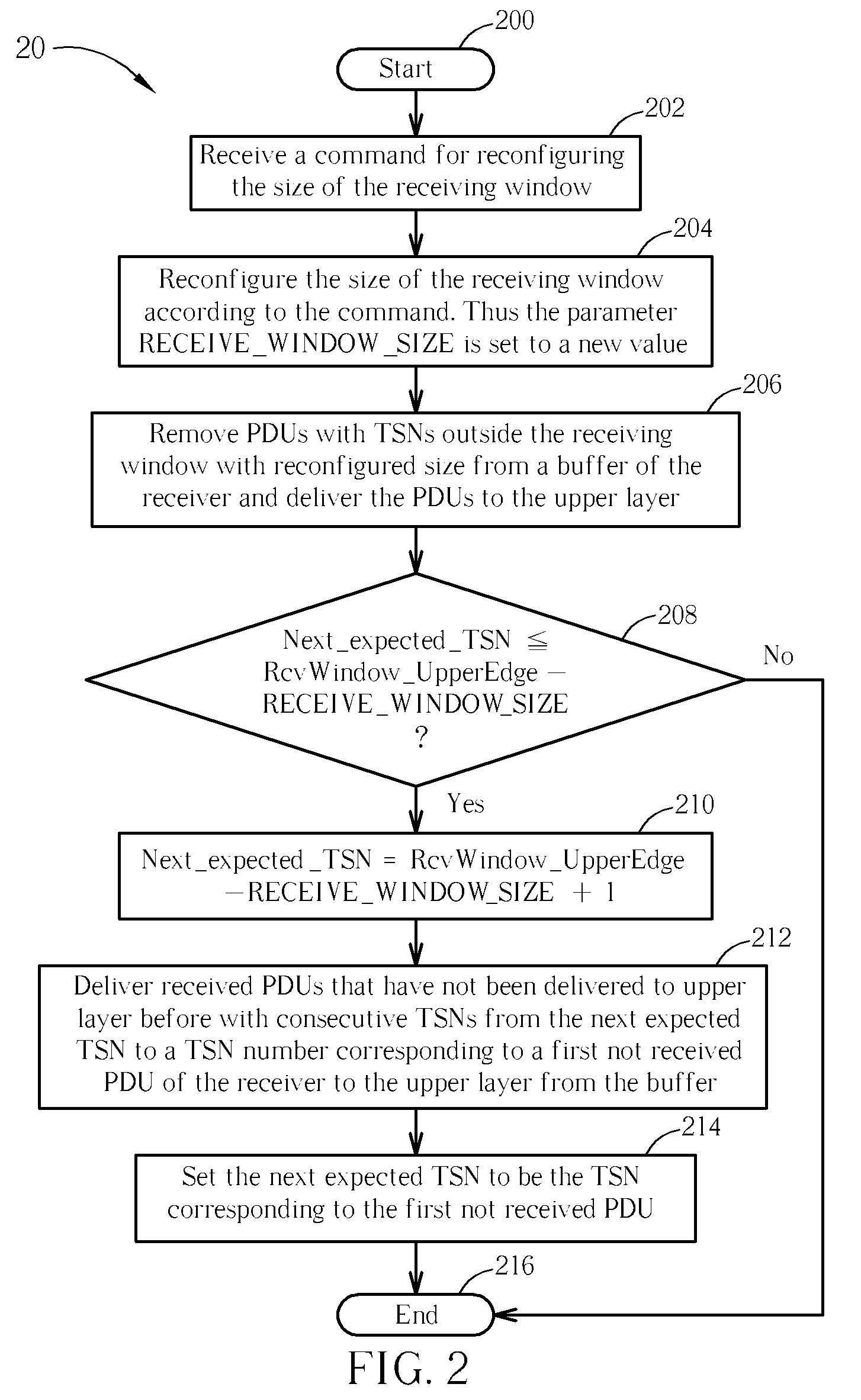

Method and Related Apparatus for Reconfiguring Size of a Receiving Window in a Communications System

ActiveUS20060221833A1Reduce memory sizeReduce window sizeError prevention/detection by using return channelSynchronising transmission/receiving encryption devicesCommunications systemRe-order buffer

A method for reconfiguring size of a receiving window in a communications system avoiding duplicate packet delivery to an upper layer to keep ciphering parameters in synchronization when the communications system reconfigures a receiving window of a receiver includes receiving a command for reconfiguring a size of the receiving window, reconfiguring the size of the receiving window according to the command, removing packets with sequence numbers outside the receiving window from buffers of the receiver and delivering the packets to the upper layer, determining whether a sequence number of a next expected packet is below the receiving window, and keeping the sequence number of the next expected packet and the packets in a reordering buffer of the receiver unchanged when the sequence number of the next expected packet is not below the receiving window.

Owner:INNOVATIVE SONIC

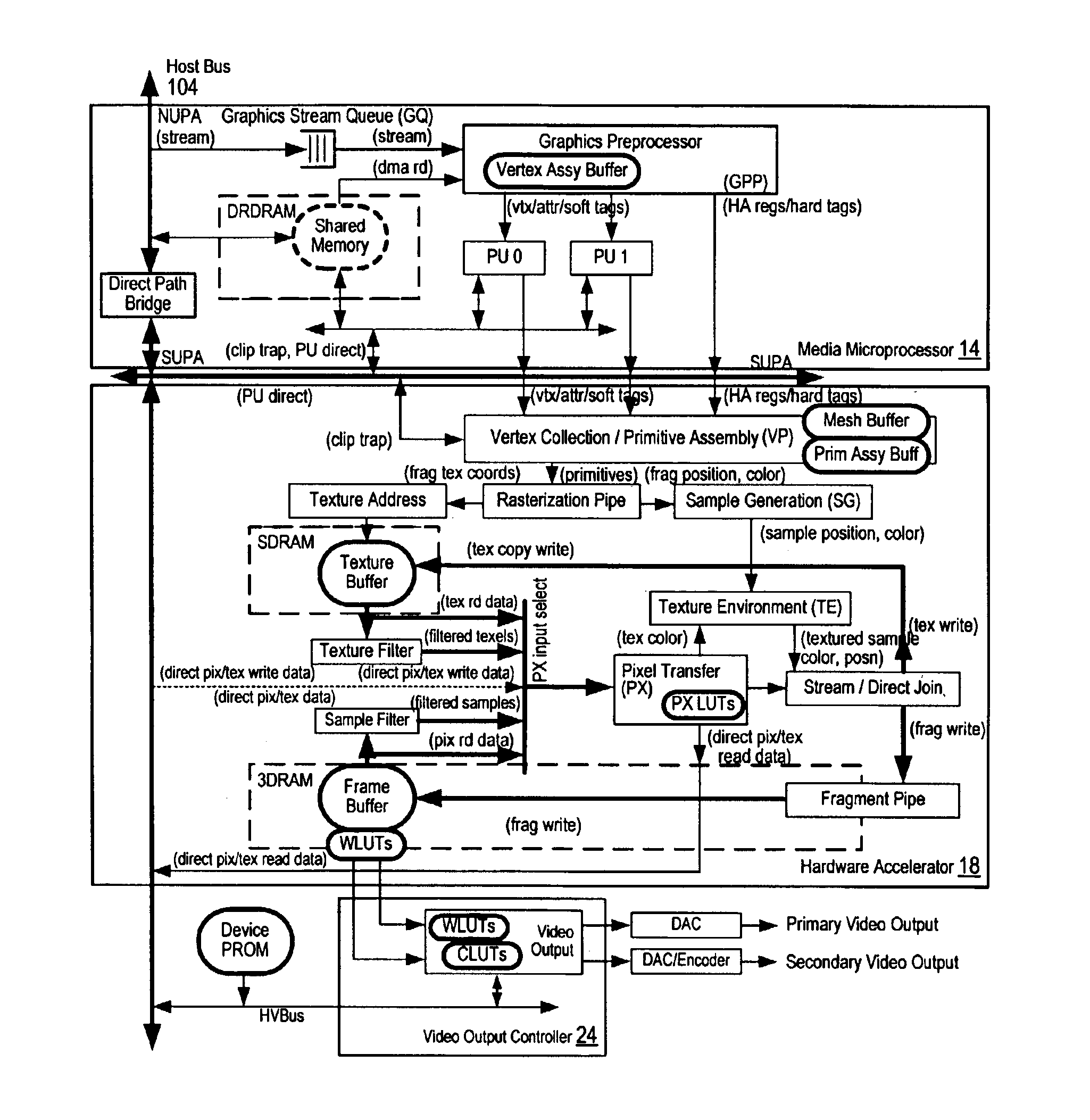

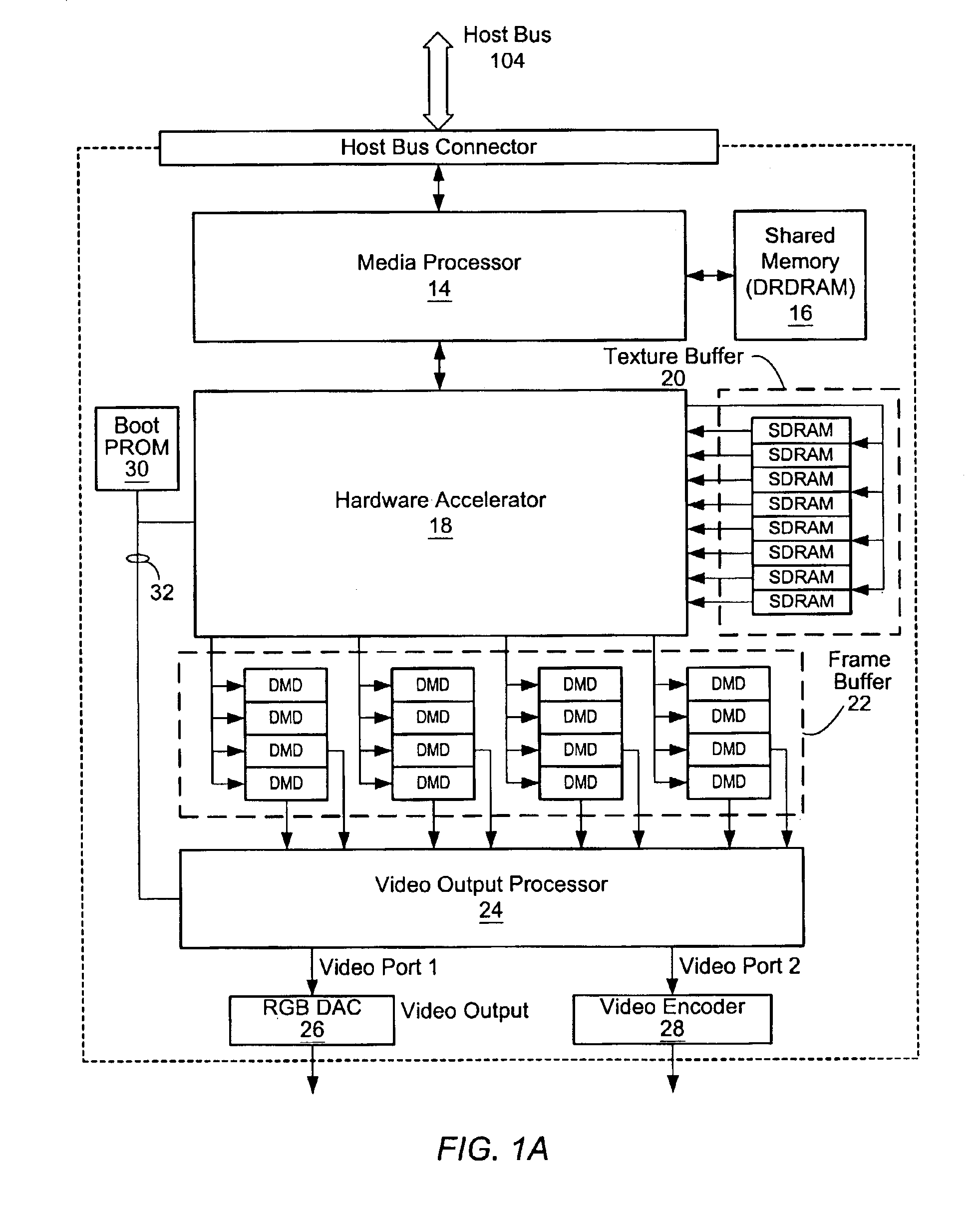

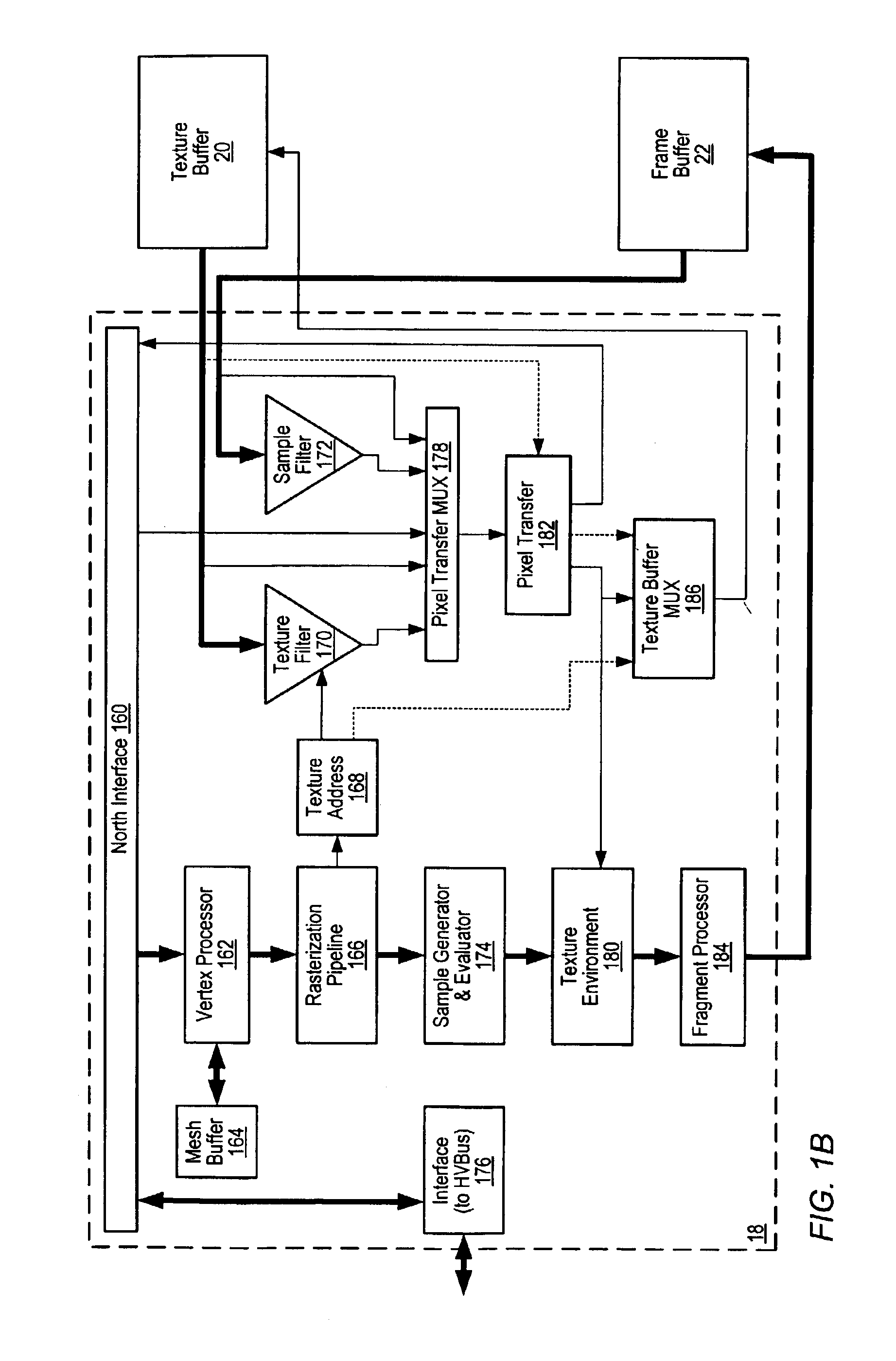

Dynamically adjusting sample density in a graphics system

InactiveUS6999087B2Maximized sample densityImprove image qualityMemory adressing/allocation/relocationCathode-ray tube indicatorsProgram instructionGraphic system

A graphics system may include a frame buffer and a hardware accelerator. The frame buffer may include a sample buffer and a double-buffered display area. The hardware accelerator may be coupled to the frame buffer, and configured (a) to receive primitives, (b) to generate samples for the primitives based on a dynamically adjustable sample density value, (c) to write the samples into the sample buffer, (d) to read the samples from the sample buffer, (e) to filter the samples to generate pixels, (f) to store the pixels in a back buffer of the double-buffered display area. A host computer may be configured (e.g., by means of stored program instructions) to dynamically update programmable registers of the graphics system to reallocate the sample buffer in the frame buffer in response to user input specifying a change in one or more window size parameters.

Owner:ORACLE INT CORP

Loss tolerant transmission control protocol

InactiveUS7366132B2Reduce congestionReduce window sizeNetwork traffic/resource managementTime-division multiplexCongestion windowGranularity

Provided are apparatuses and methods for transmitting or receiving data packets in a data block in a communication network with a transport protocol. In one example, a loss tolerant TCP protocol is used in which a maximum segment size (MSS) may be adapted to a minimum granularity of a congestion window. Also, proactive forward error correction (FEC) packets may be added to a window of the data block. The number of proactive FEC packets may be determined, for example, based on an estimate erasure rate. In addition, reactive FEC packets may be added to the data block. Also, a receiver may receive data packets in a data block and process a selective acknowledgment (SACK) responsive to the data packets received.

Owner:RENESSELAER POLYTECHNIC INST +1

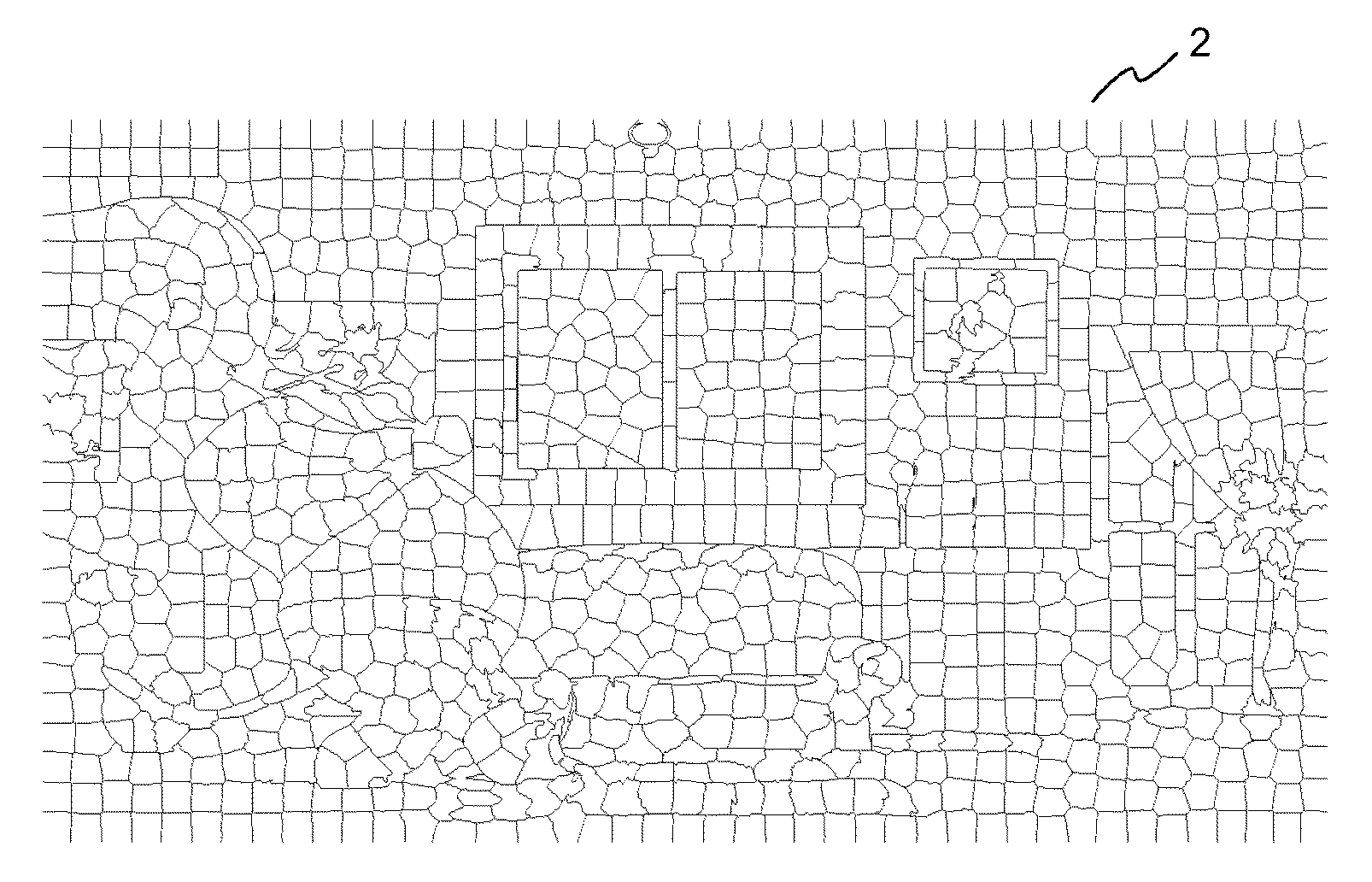

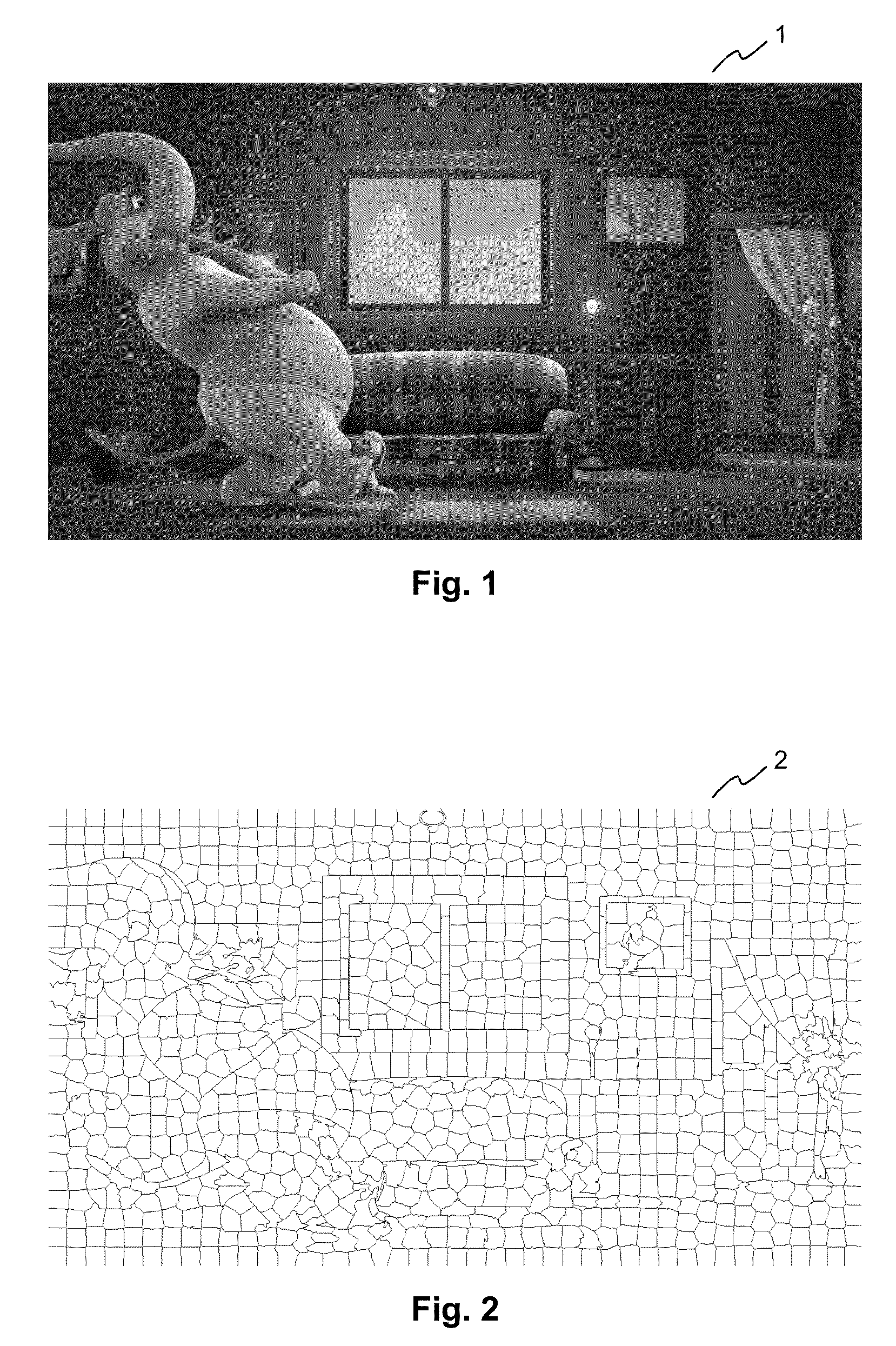

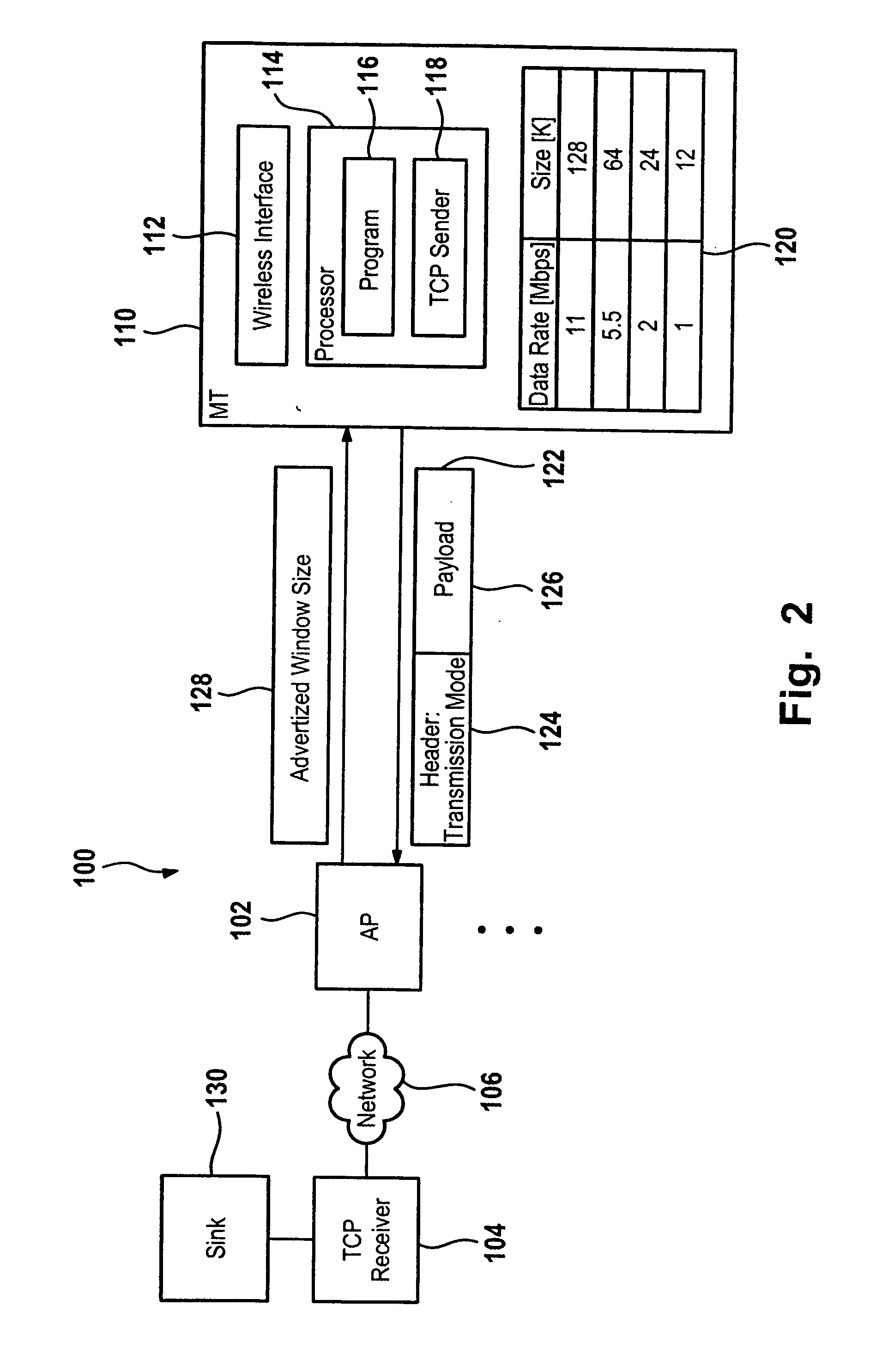

Temporally consistent superpixels

ActiveUS20130342559A1Improving temporal consistencyImprove consistencyImage enhancementImage analysisPattern recognition

Owner:INTERDIGITAL VC HLDG INC

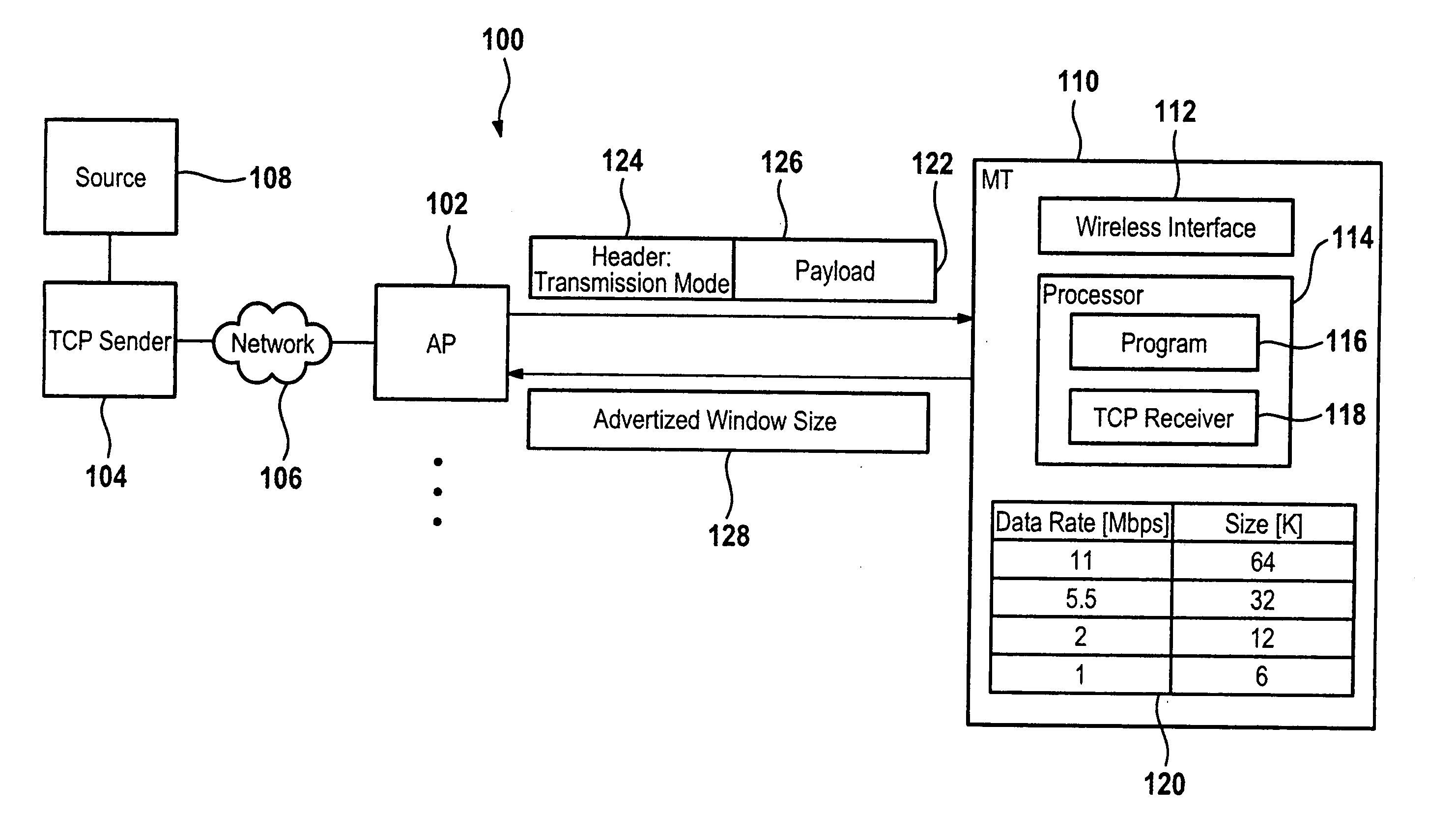

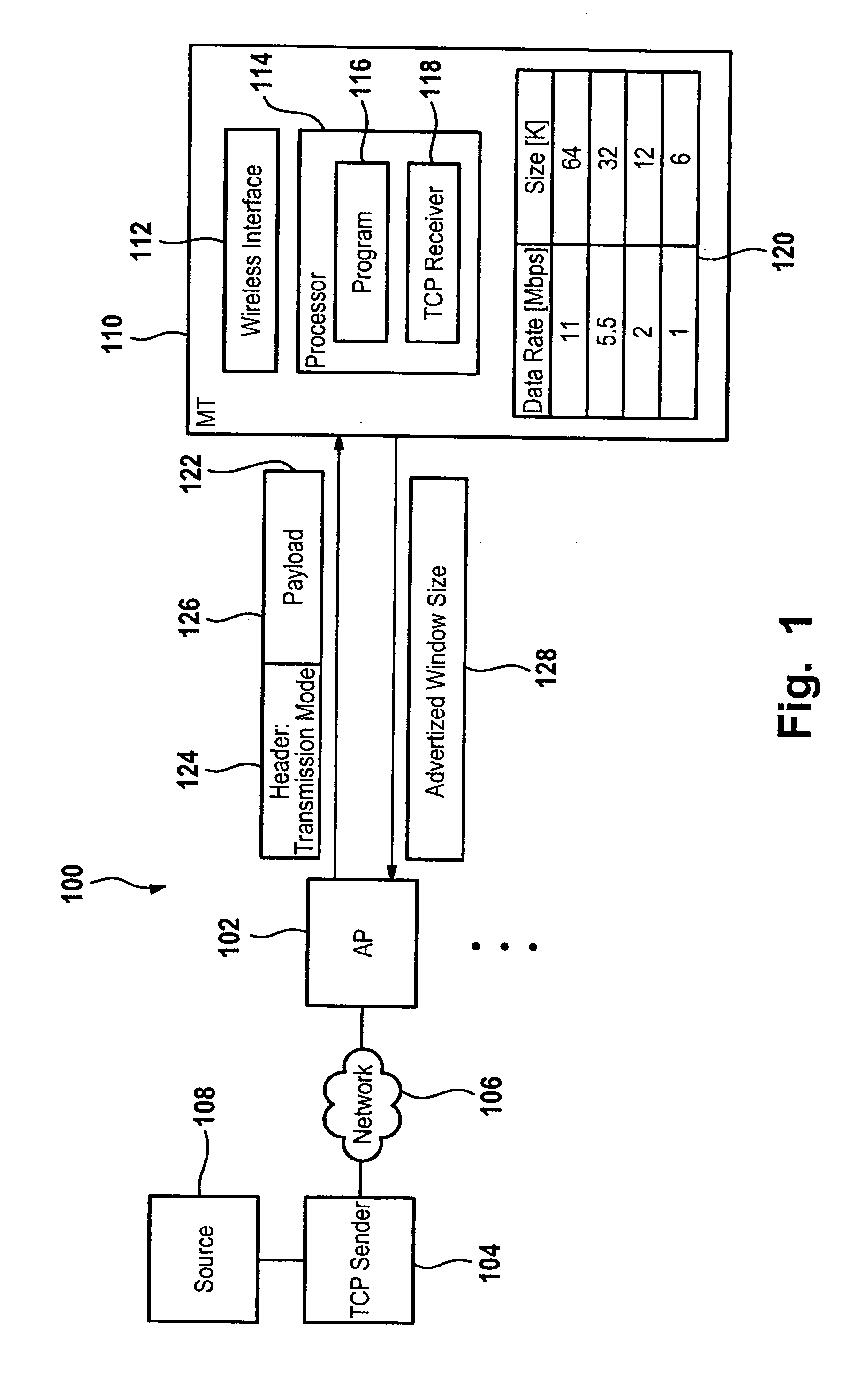

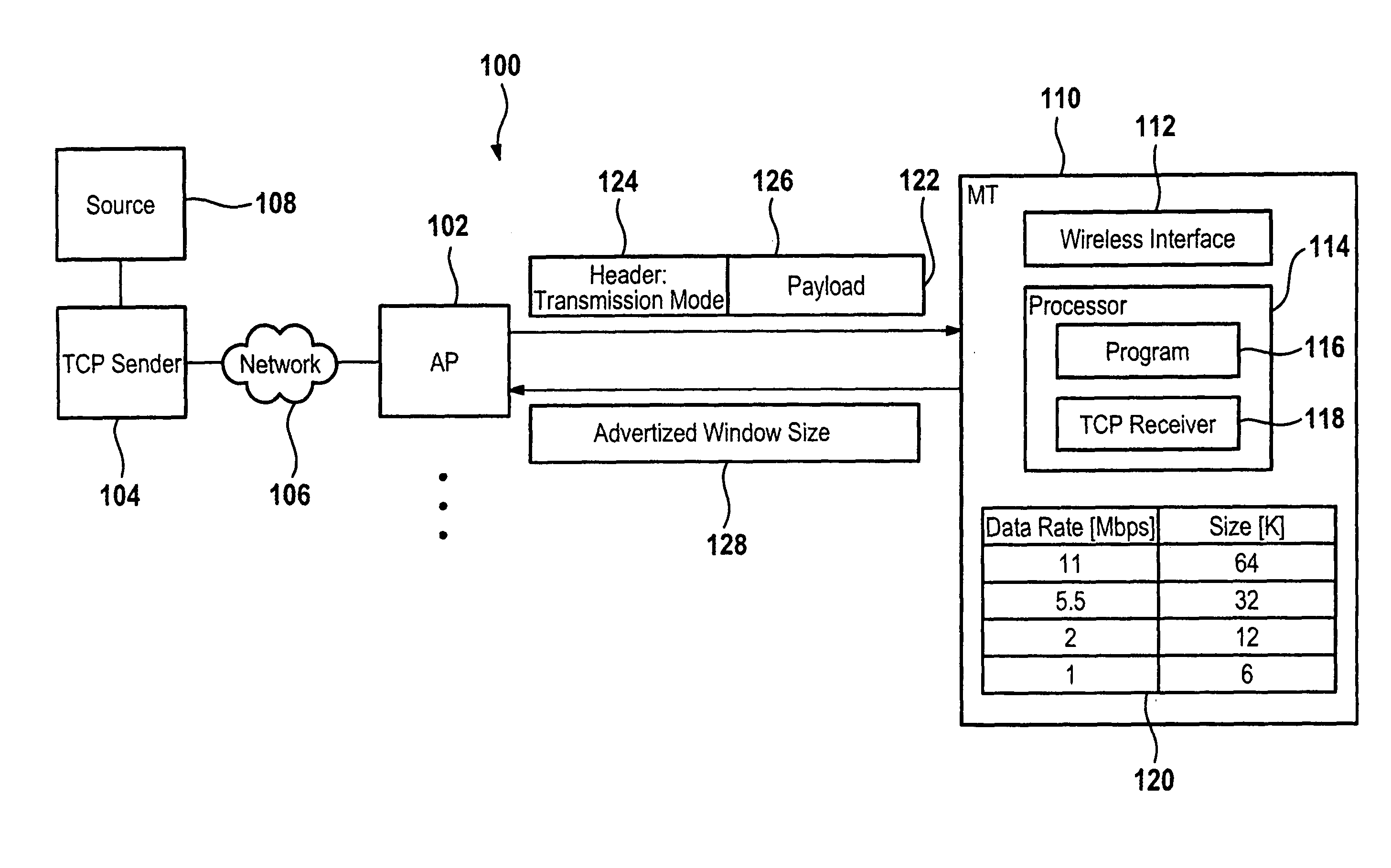

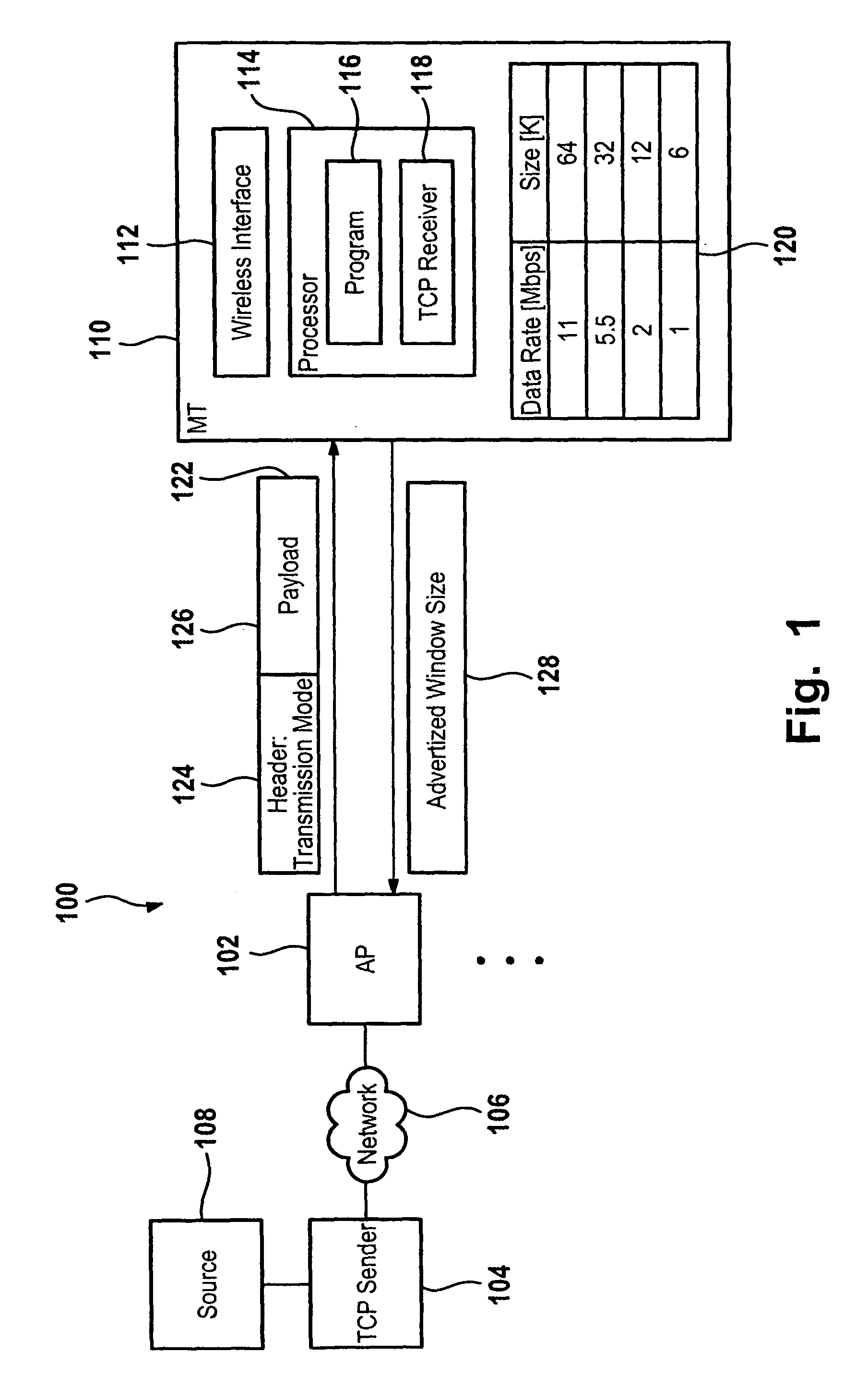

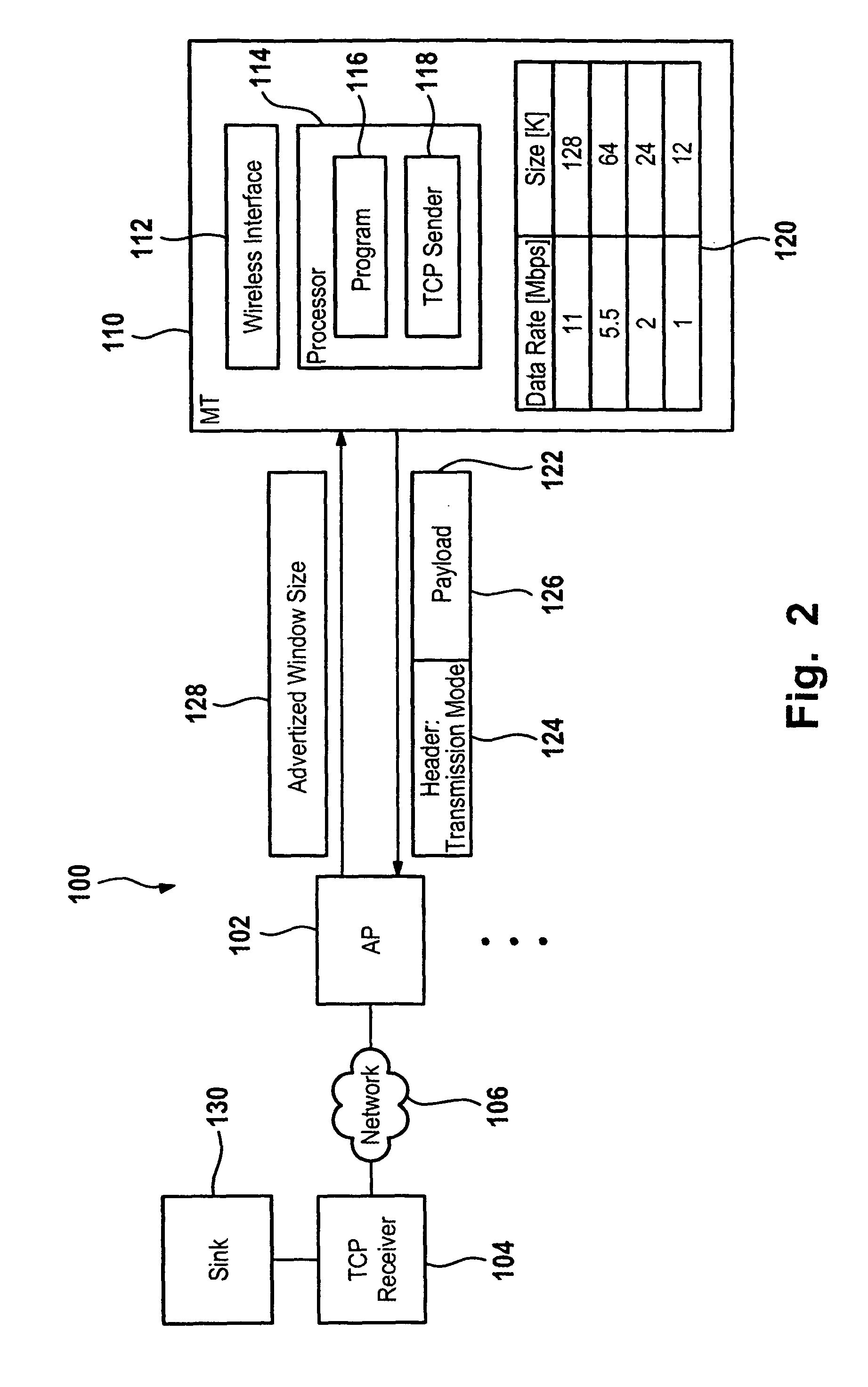

Wireless mobile terminal and telecommunication system

ActiveUS20050243718A1Reduce data rateEffect data transmission capacityError prevention/detection by using return channelFrequency-division multiplex detailsTelecommunicationsData rate

The present invention relates to a wireless mobile terminal comprising: TCP receiver means (118) means (120) for determining a size of an advertised window depending on a data rate of a wireless downlink transmission.

Owner:RPX CORP

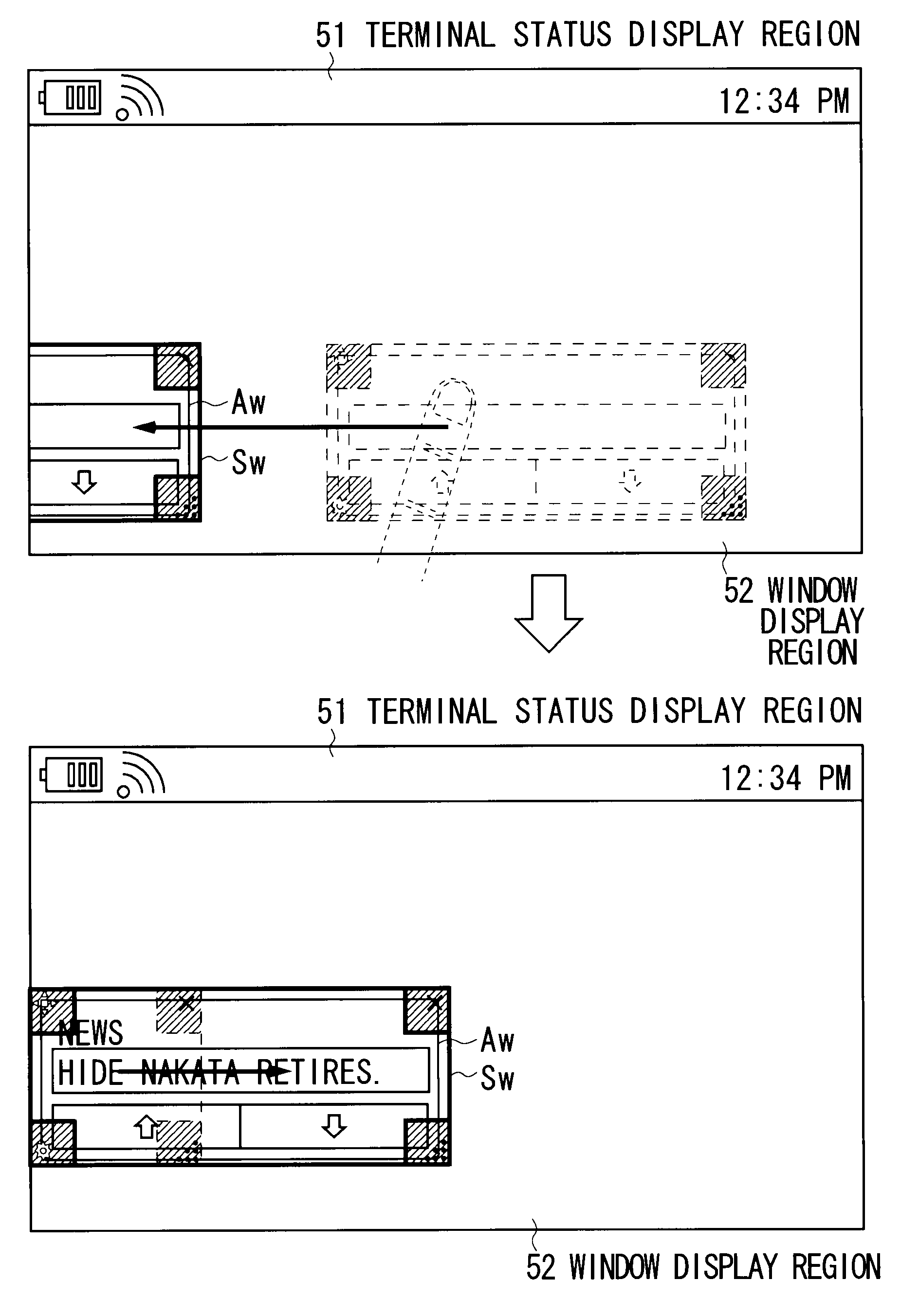

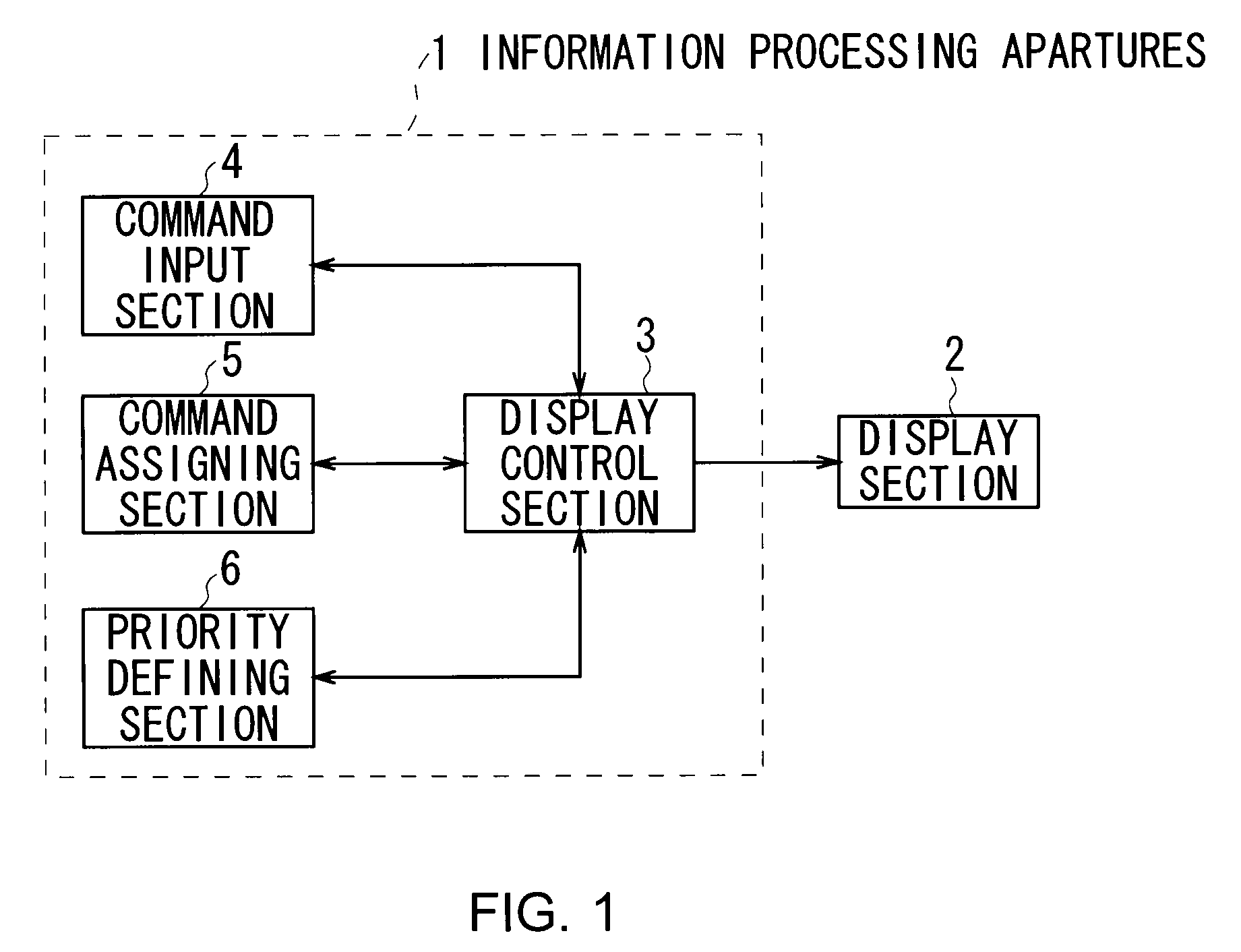

Information processing apparatus, display control method and display control program

ActiveUS8631345B2Small sizeReduce window sizeCathode-ray tube indicatorsInput/output processes for data processingInformation processingDisplay size

An information processing apparatus includes: a display control section for displaying a window showing a first icon and a second icon of a predetermined display size on a display screen. The display control section reduces the display size of at least either the first icon or the second icon so as not to overlap with each other if it determines that the icons overlap with each other when it alters a display area of the window being displayed on the display screen.

Owner:SONY CORP

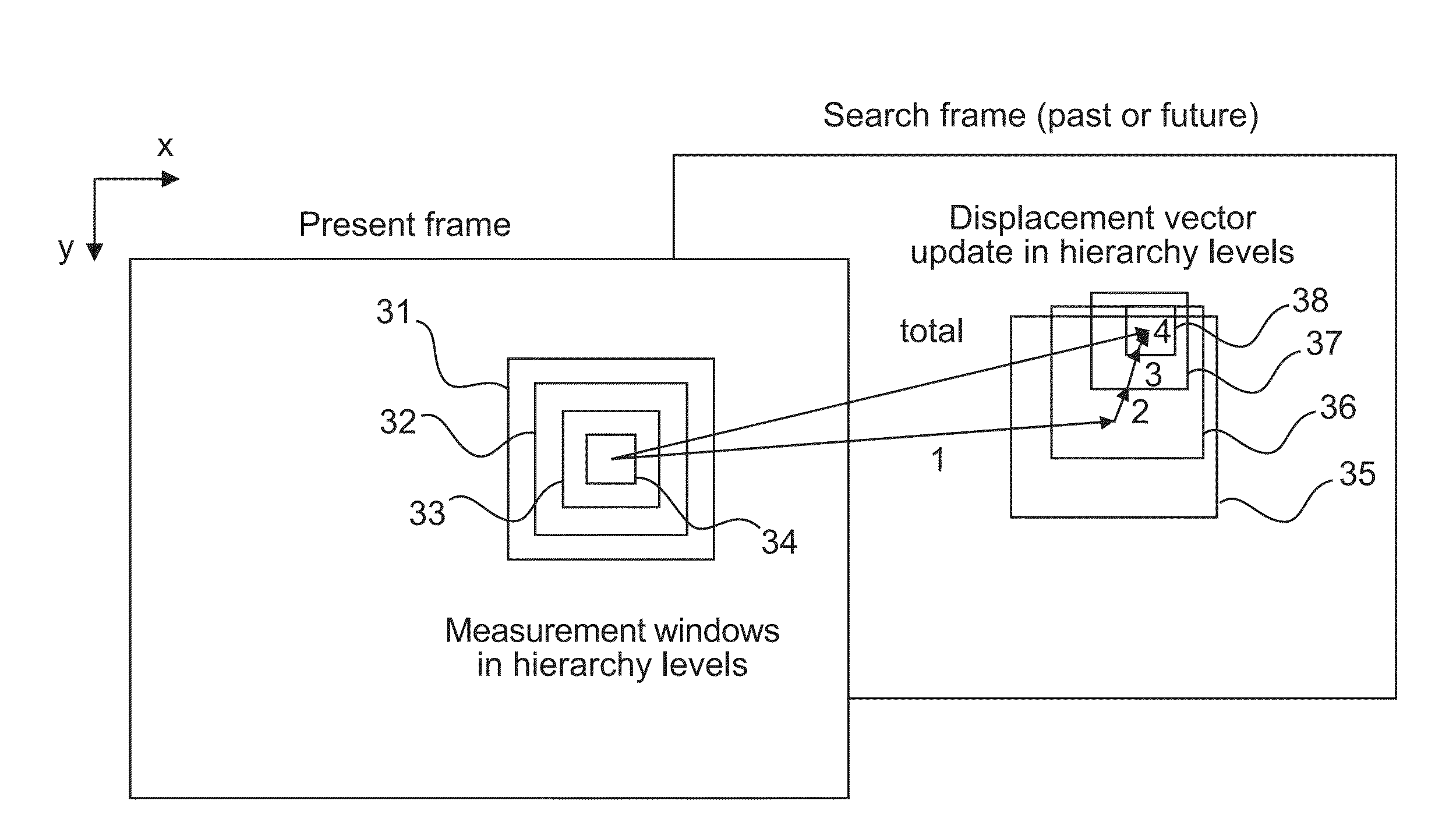

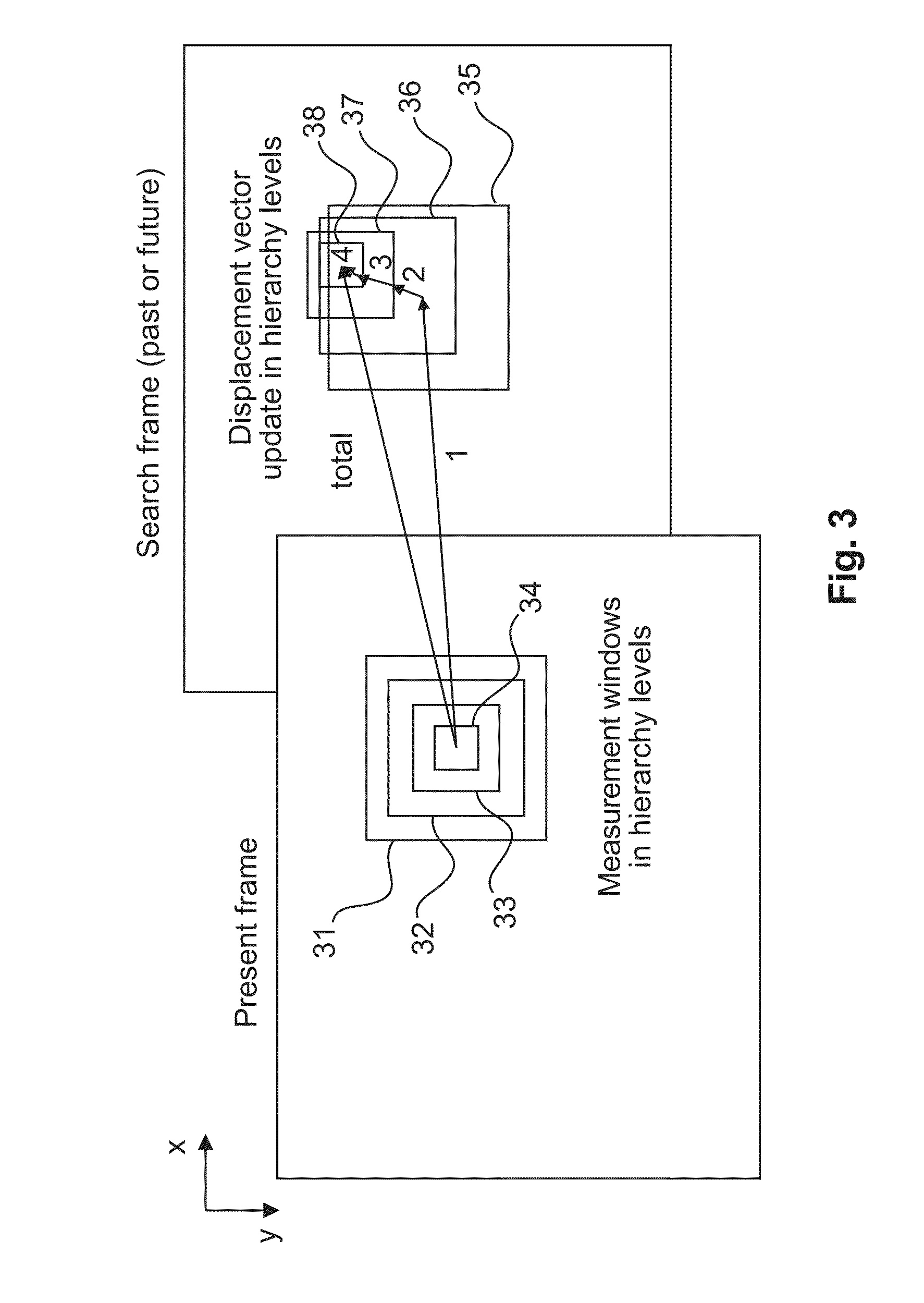

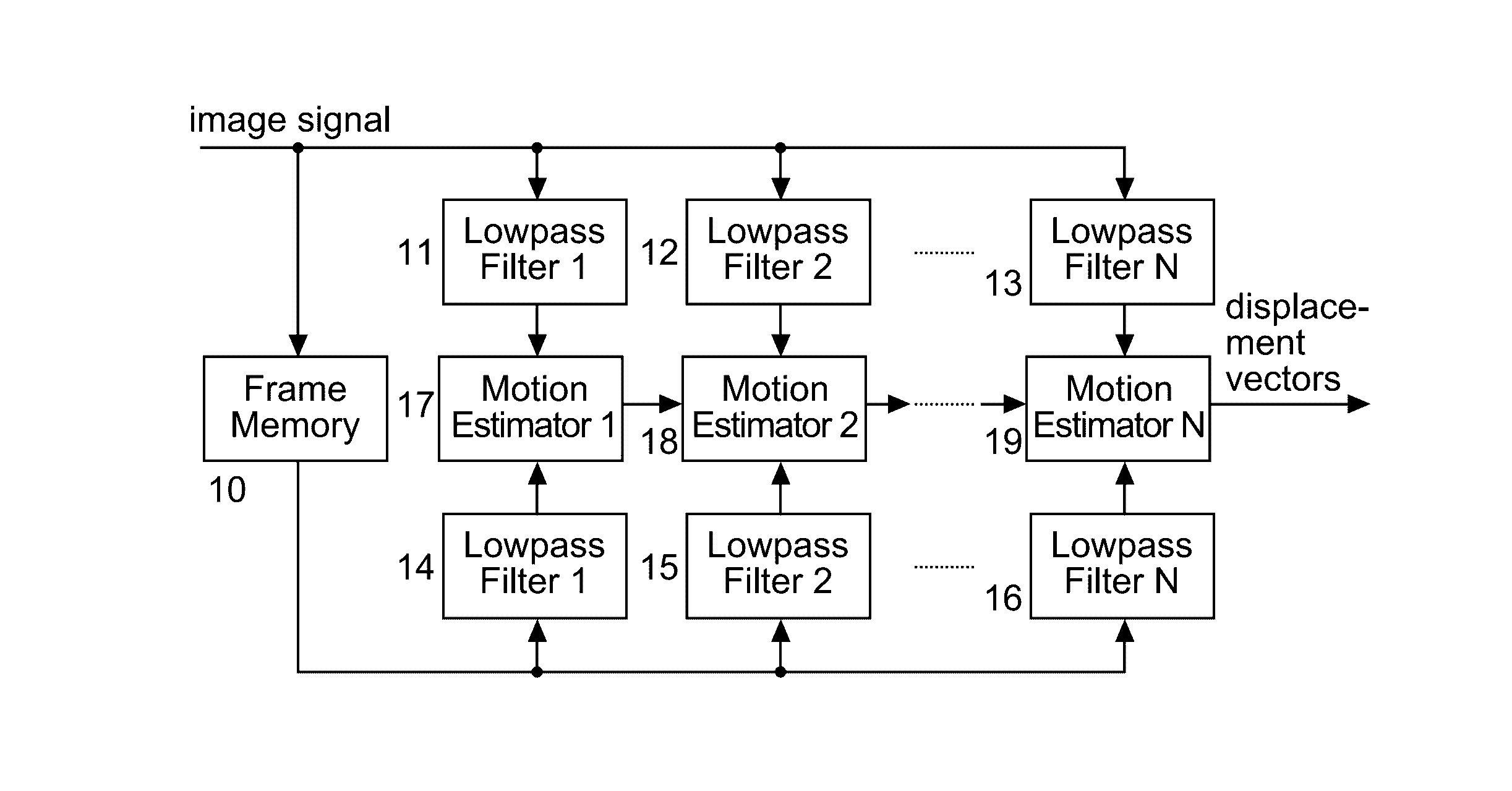

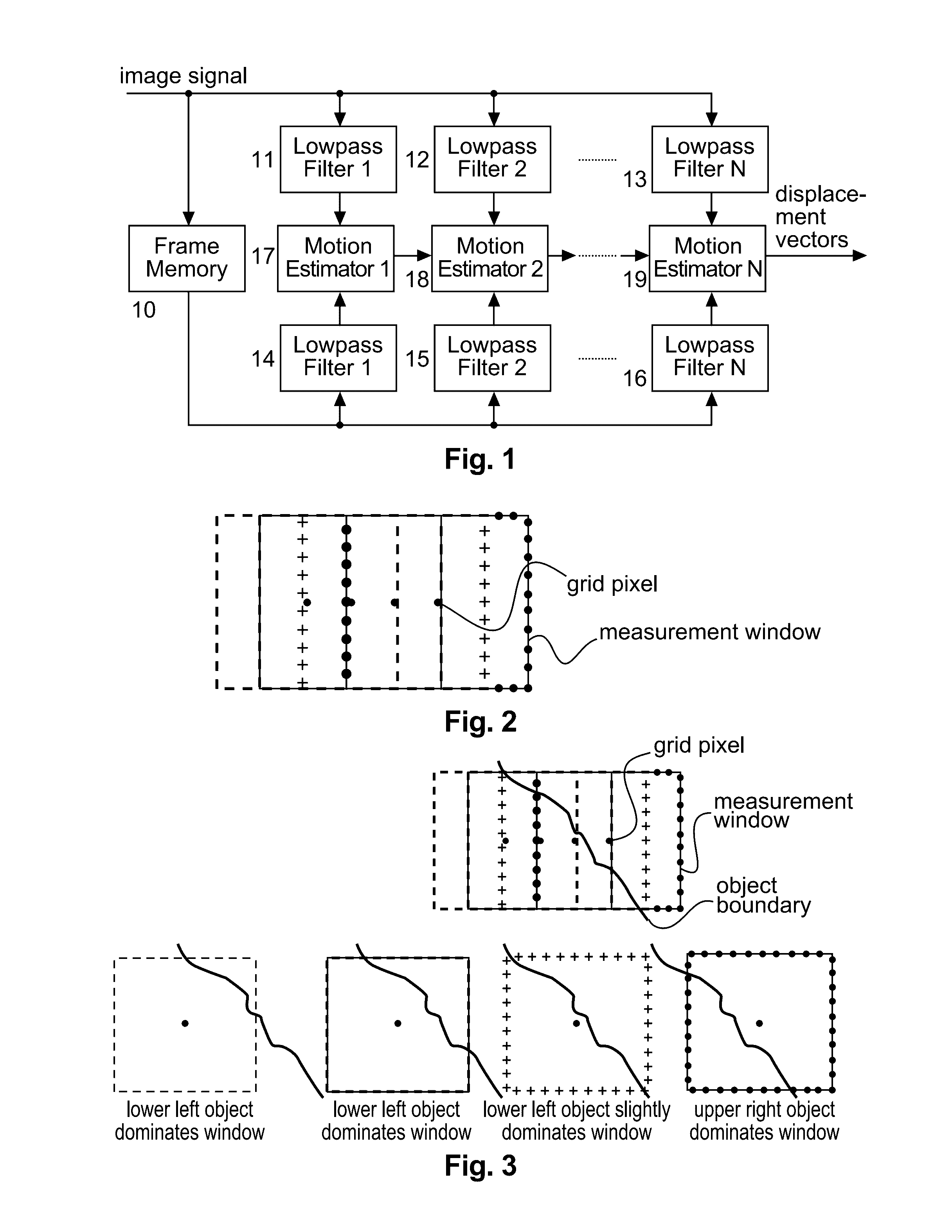

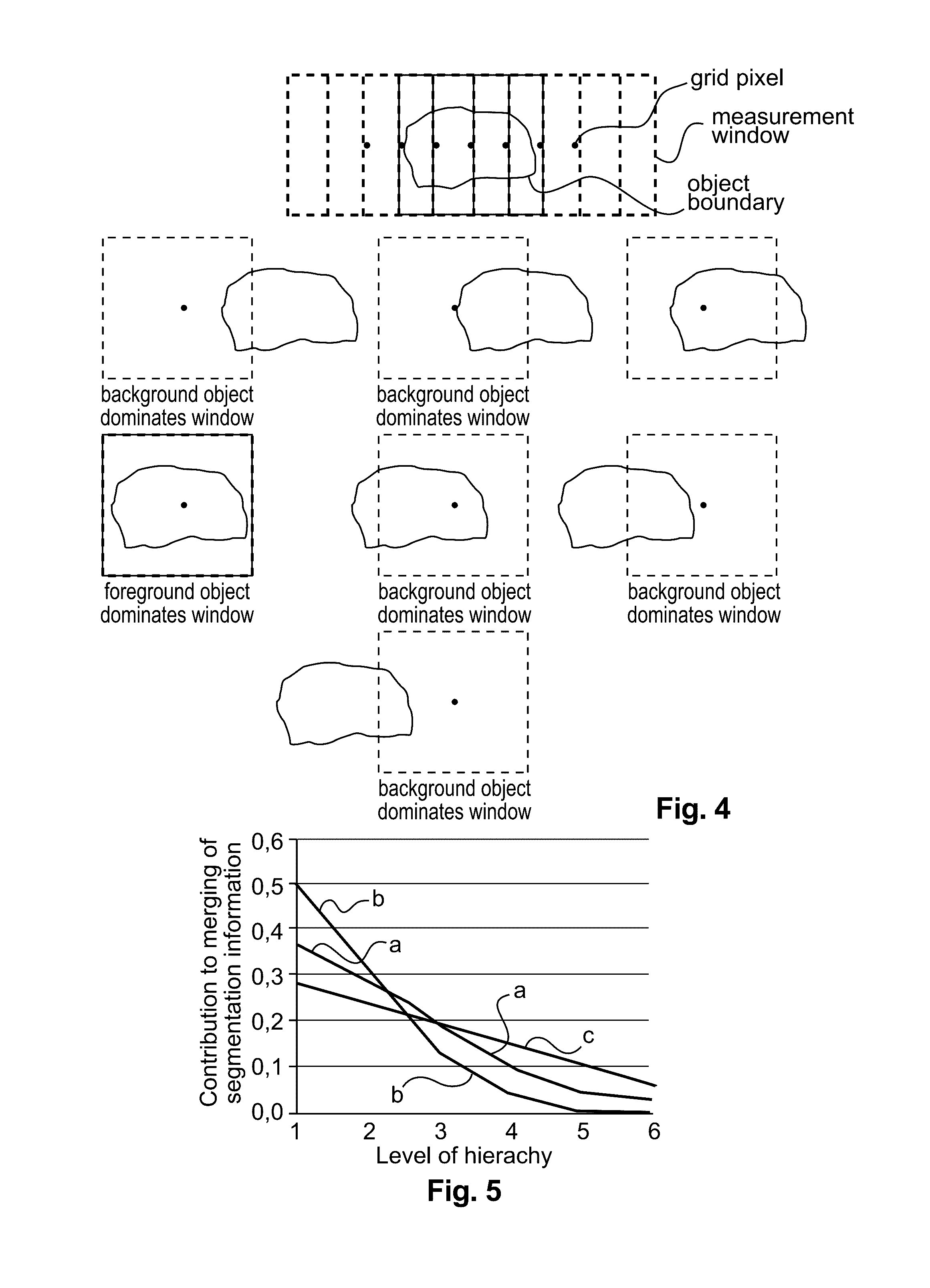

Method and apparatus for hierachical motion estimation in the presence of more than one moving object in a search window

InactiveUS20160225161A1Reliable motion estimationReduce filter strengthImage enhancementTelevision system detailsFrame differencePixel density

In hierarchical motion estimation motion vectors are refined in successive levels of increasing search window pixel density and / or decreasing search window size. Within each hierarchical level, after finding an optimum vector at at least one pixel, based on the optimum vector, the absolute displaced frame difference or displaced frame difference for each pixel of the search window is determined. Within the search window, two or more groups of these pixels are determined, wherein each of these pixel groups is characterized by a different range of absolute displaced frame difference values or displaced frame difference values for the pixels. A segmentation of the search window into different moving object regions is carried out by forming pixel areas according to the groups, which areas represent a segmentation mask for the search window. For at least one of the segmentation areas a corresponding motion vector is estimated.

Owner:THOMSON LICENSING SA

Optimized windows and interpolation factors, and methods for optimizing windows, interpolation factors and linear prediction analysis in the ITU-T G.729 speech coding standard

InactiveUS20070055504A1Reduce window sizeFuture buffering requirementSpeech analysisObjective qualitySpeech code

Alternate window optimization procedures and / or LSP interpolation factor optimization procedures are used to improve the ITU-T G.729 speech coding standard (the “Standard”) by replacing the window used by the Standard with an optimized window and / or replacing the LSP interpolation factor used by the standard with an optimized LSP interpolation factor. Optimized windows created using the alternate window optimization procedure and / or optimized LSP interpolation factors created using the LSP interpolation factor optimization procedure yield improvements in the objective quality of synthesized speech produced by the Standard. In many cases, improvements are obtained using shorter windows, which results in reduced computational cost and / or smaller future buffering requirements, which results in lowered coding delay. The improved Standard, procedures, and optimized windows and LSP interpolation factors can all be implemented as computer readable software code and in optimization devices.

Owner:CHU WAI CHUNG +1

Method and apparatus for hierarchical motion estimation using dfd-based image segmentation

InactiveUS20170041632A1Improve accuracyImprove reliabilityImage enhancementImage analysisFrame differenceMotion vector

In hierarchical motion estimation, in each motion estimation hierarchy level, a pixel block matcher for comparing correspondingly sampled pixel values of a current image and a delayed previous image is used in order to compute a motion vector for every pixel. By evaluating displaced frame differences in the measurement window, a segmentation of the measurement window into different moving object regions is performed. The corresponding segmentation information is stored, and the stored segmentation information is used as an initial segmentation mask for motion estimation in the following finer level of the motion estimation hierarchy. In the following finer level of the motion estimation hierarchy an updated segmentation information is determined. This processing continues until the finest level of said motion estimation hierarchy is reached. The resulting segmentation information values of successive search window positions can be combined.

Owner:THOMSON LICENSING SA

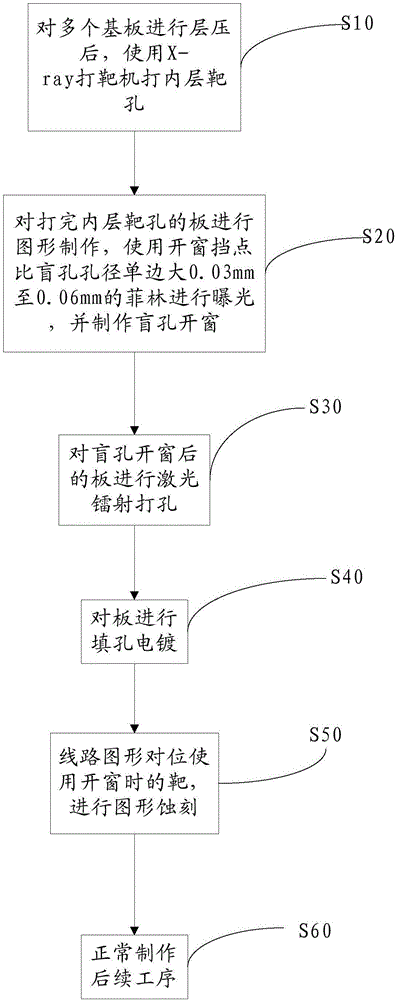

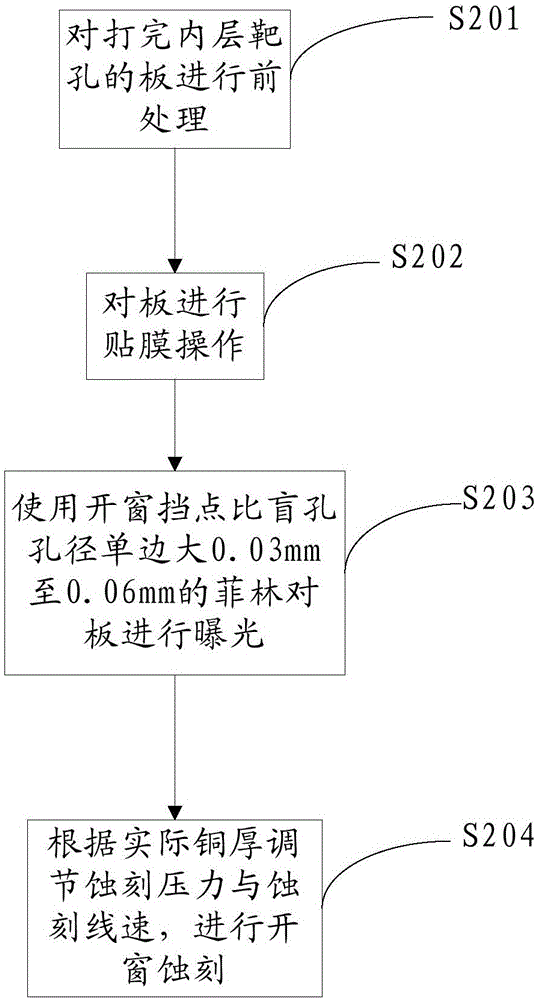

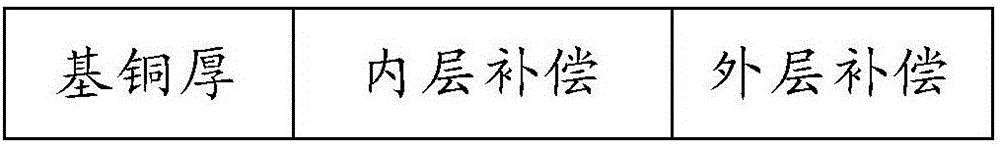

Blind hole window manufacturing method capable of improving unfilled hole filling

The invention relates to a blind hole window manufacturing method capable of improving unfilled hole filling. The blind hole window manufacturing method comprises the following steps: laminating a plurality of base plates, and then punching an inner-layer target hole by adopting an X-ray target shooting machine; manufacturing a graph on the plate subjected to inner-layer target hole punching, carrying out exposure by utilizing a film with a window stopping point which is 0.03mm to 0.06mm larger than a single edge of the hole diameter of a blind hole, and manufacturing a blind hole window; carrying out laser punching on the plates with the blind hole windows; carrying out hole filling electroplating on the plates; carrying out graph etching by utilizing a target for forming the window in a line graph alignment process; and normally carrying out a subsequent manufacturing procedure. According to the blind hole window manufacturing method provided by the invention, the problem that the hole filling is not full is solved through reducing the sizes of the blind hole windows; when through holes and the blind hole exist at the same time, graphs are aligned by utilizing a blind hole alignment hole and the quality of the blind hole is guaranteed preferably, so that the quality problem that the pad in a tangent position of the blind hole and pad is etched can be avoided; and pad etching rejection caused by the fact that hole sealing of a blind hole sticking film is not good when an outer-layer graph is manufactured is greatly reduced, the cost is saved, and the rejection rate is reduced.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

Method of controlling a receiver and a transmitter in a wireless communication system to handle a transmission window size change procedure

InactiveUS20050041585A1Decrease size of transmission windowImproves radio transmission efficiencyError prevention/detection by using return channelFrequency-division multiplex detailsCommunications systemSize change

A method of controlling a receiver and a transmitter to handle a transmission window size change procedure is disclosed. The method includes driving the receiver to deliver a control message having a window size parameter to the transmitter for adjusting a transmission window size of the transmitter, and driving the transmitter to output an acknowledgement message to the receiver and adjust the transmission window size according to the window size parameter when the transmitter receives the control message.

Owner:ASUSTEK COMPUTER INC

Network flow/stream simulation method

InactiveUS7580411B2Reduce window sizeError preventionData switching by path configurationNetwork packetLinked list

Owner:DRAYTEK

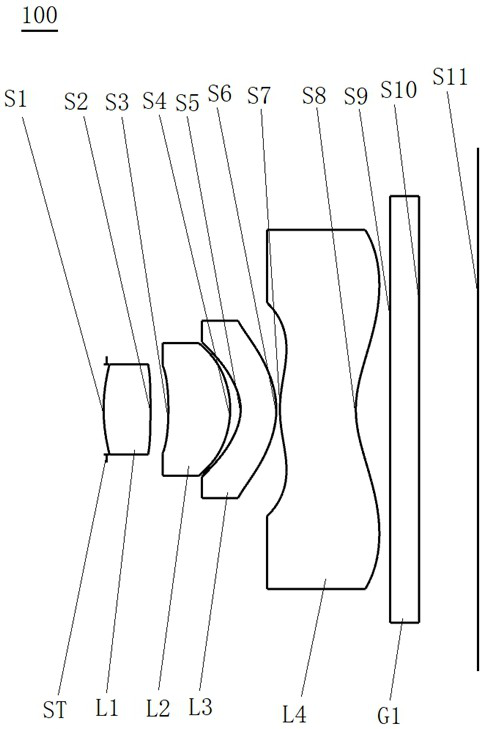

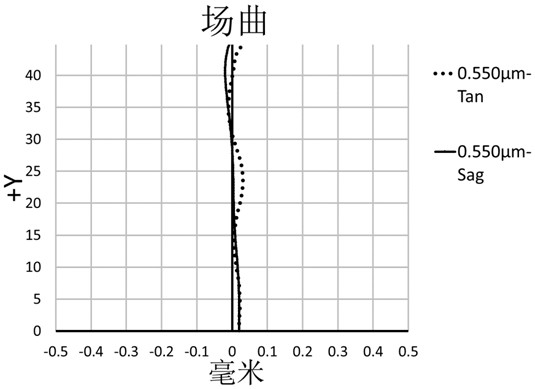

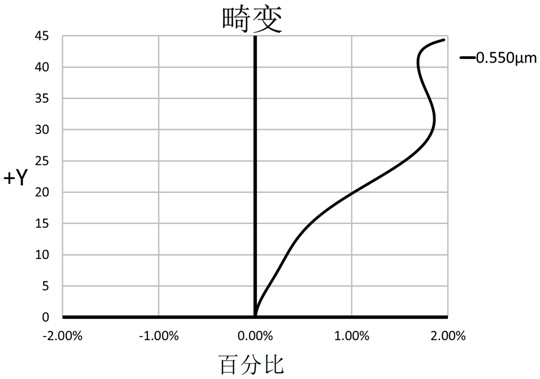

Optical lens and imaging equipment

The invention discloses an optical lens and imaging equipment. The optical lens sequentially comprises, from an object side to an imaging surface along an optical axis, a diaphragm;p a first lens with positive focal power, wherein the object side surface and the image side surface of the first lens are convex surfaces; a second lens with positive focal power, wherein the object side surface of the second lens is a concave surface, and the image side surface of the second lens is a convex surface; a third lens with negative focal power, wherein the object side surface of the third lens is a concave surface, and the image side surface of the third lens is a convex surface; a fourth lens with positive focal power, wherein the object side surface of the fourth lens is a convex surface near the optical axis, the image side surface of the fourth lens is a concave surface near the optical axis, and the object side surface and the image side surface of the fourth lens have inflection points, wherein the first lens, the second lens, the third lens and the fourth lens are all aspherical lenses, the entrance pupil diameter EPD of the optical lens is less than 0.9 mm, and the total optical length TTL of the optical lens is less than 3.8 mm. The optical lens has the advantages of small outer diameter of the head, small size and high pixel.

Owner:合肥联创光学有限公司

Combined minimally invasive cutting biopsy device for bone tumour

Owner:THE AFFILIATED DRUM TOWER HOSPITAL MEDICAL SCHOOL OF NANJING UNIV

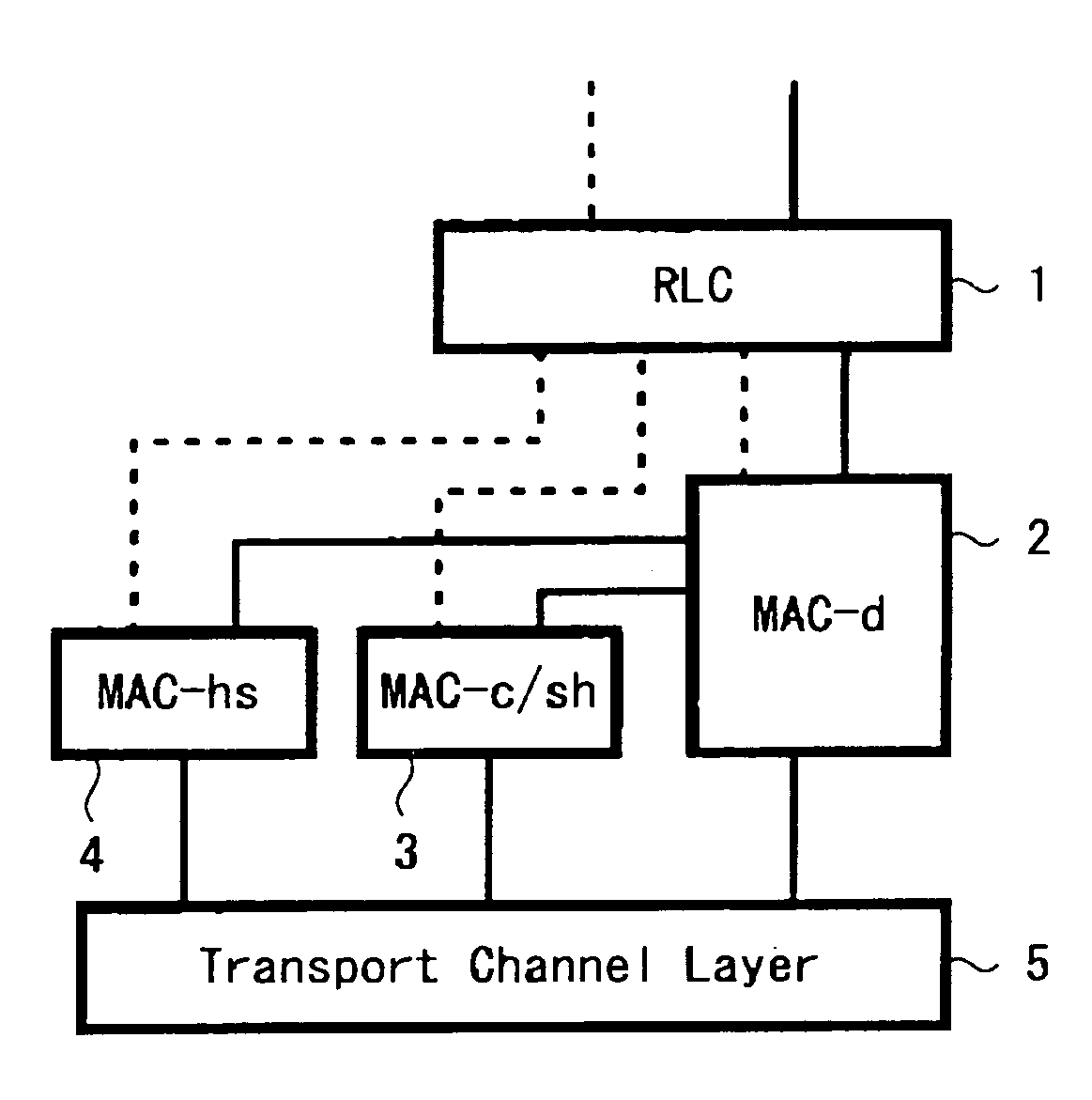

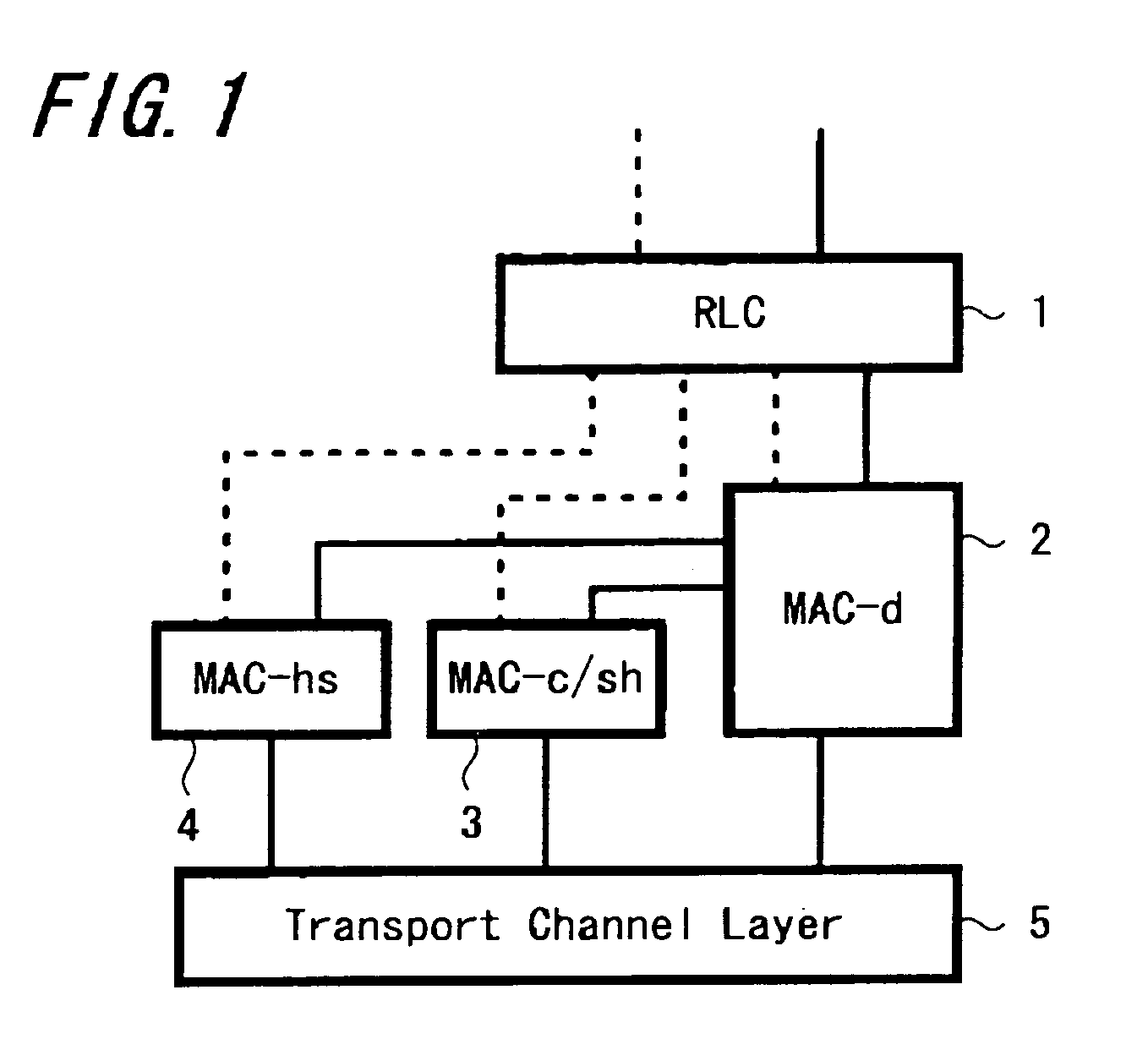

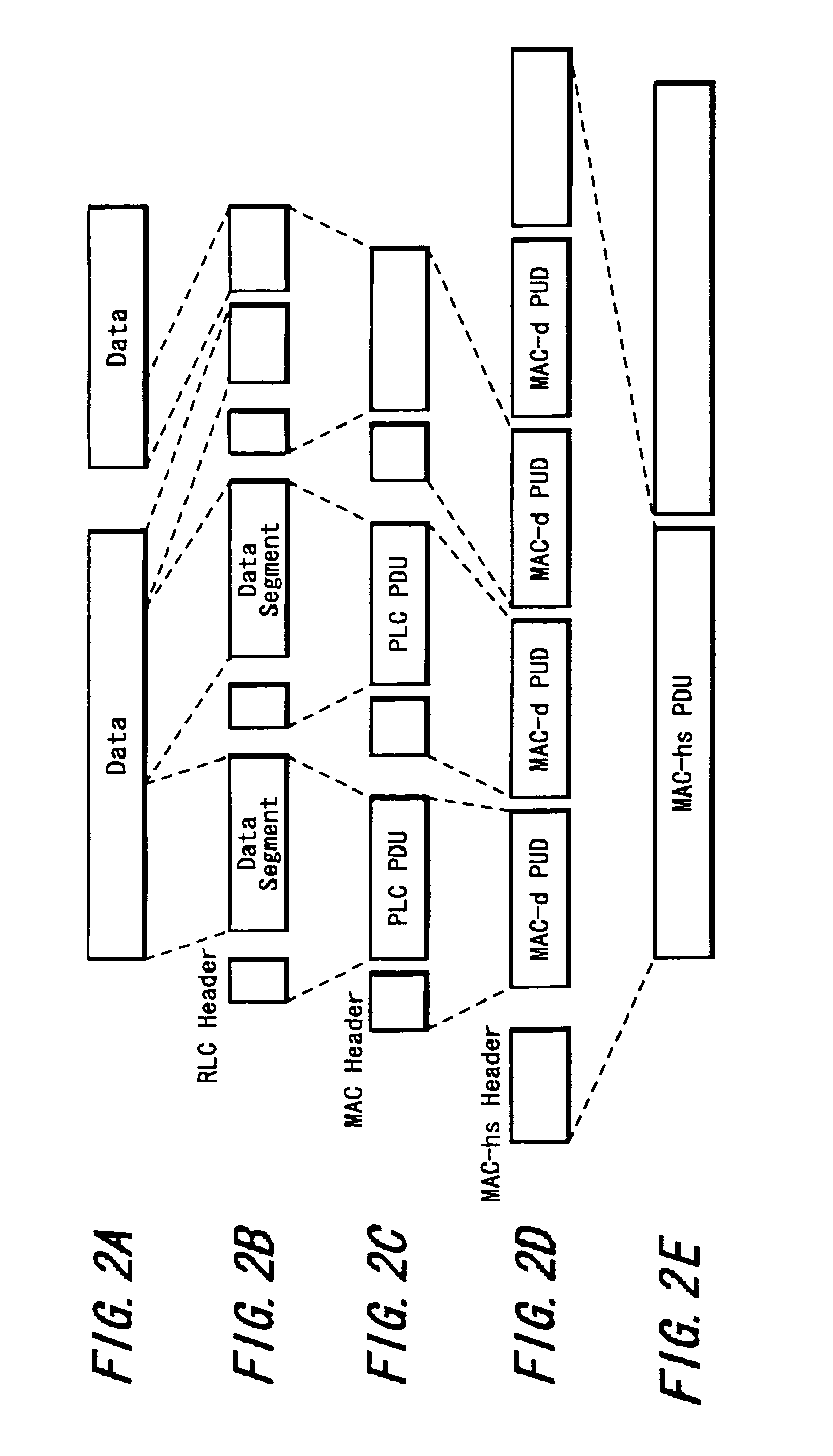

Data transmission method and data transmission apparatus

InactiveUS7619976B2Appropriate amountAvoid discardingError prevention/detection by using return channelFrequency-division multiplex detailsComputer hardwareWireless transmission

When retransmission requests are issued based on the results of error-correction decoding of received data packets to perform data transmission, statistical information indicating whether received data packets have been successfully decoded or have not been decoded is acquired, and based on the rate at which correct decoding has been made or the rate at which correct decoding has not been made, which is obtained from the statistical information, a request is transmitted to the transmission source to change the window size, which is the number of data units handled in a predetermined layer, so that when for example the communication environment is not excellent, processing can be performed at a small window size, and the occurrence of circumstances in which data retransmission and the discarding of received data are repeated can be efficiently prevented. Accordingly, data transmission efficiency in a wireless transmission system performing high-speed data transmission is improved under conditions of a poor radio wave environment.

Owner:SNAPTRACK

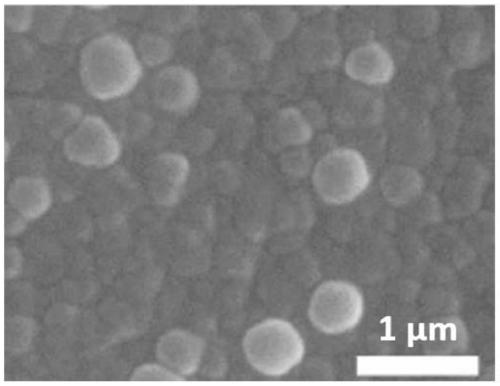

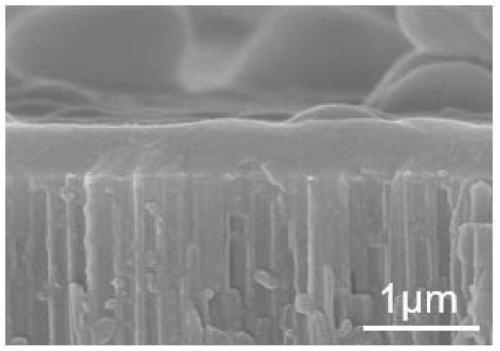

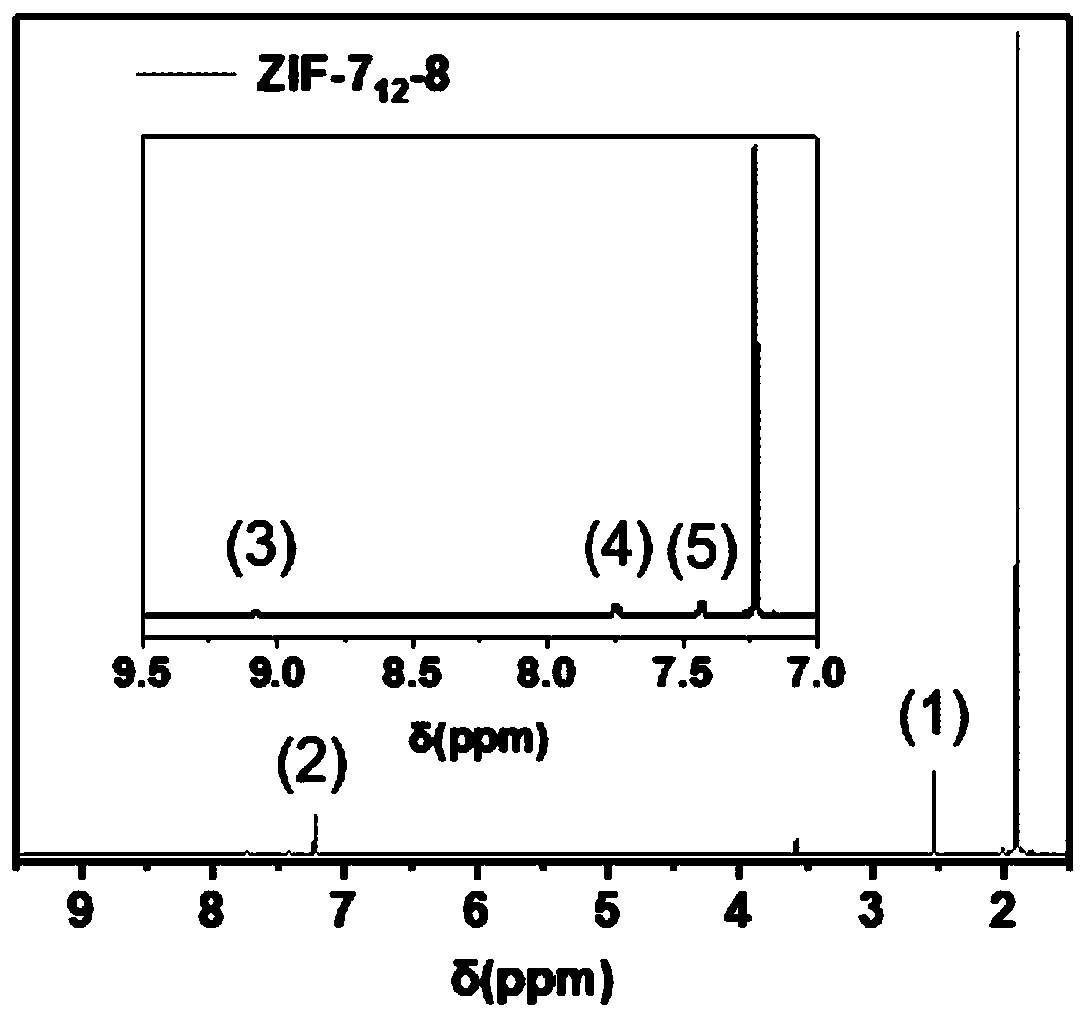

Method for preparing biligand film by utilizing in-situ electric field and biligand film prepared by method

InactiveCN109865435AEliminate post-processingFlawlessSemi-permeable membranesPower flowMixed materials

The invention discloses a method for preparing a biligand film by utilizing an in-situ electric field and the biligand film prepared by the method. The method comprises the following steps: (1) mixingzinc acetate dihydrate and dimethylimidazole, dissolving the mixed material into a solvent to obtain a solution A, and dissolving benzimidazole into a solvent to obtain a solution B; (2) adding the solution A obtained in the step (1) into the solution B, performing mixing, and allowing the mixed material to stand, wherein an appropriate amount of mixed solution is used as a precursor liquid; and(3) immersing a substrate into the precursor liquid obtained in the step (2), applying an electric current for a reaction to obtain the biligand film. The method provided by the invention prepares thebiligand film by the in-situ electric field method, the method is simple and rapid, greatly improves the production efficiency, and has good universality; the biligand film prepared by the in-situ electric field method has no obvious defects on the surface, and has good contact with the substrate without obvious cracks; and the simple high-efficiency in-situ electric field method used in the invention can be completed at normal temperature and pressure, and has no special requirements on the substrate, thereby providing a possibility for mass production.

Owner:SOUTH CHINA UNIV OF TECH

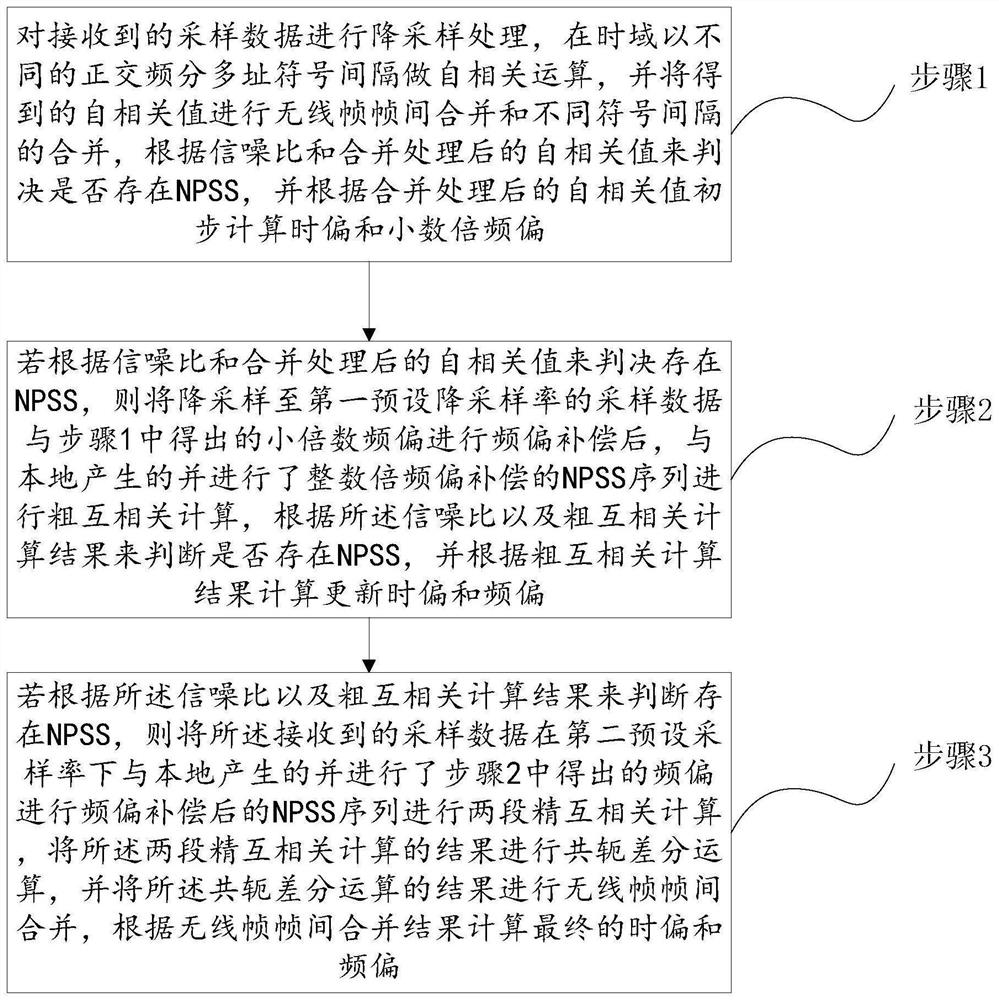

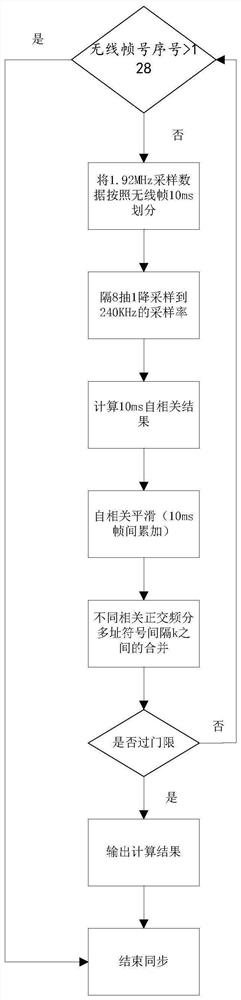

Calculation method in time-frequency synchronization process

ActiveCN112039811AImprove the correct judgment rateReduce window sizeMulti-frequency code systemsHigh level techniquesTime domainAlgorithm

The invention discloses a calculation method in a time-frequency synchronization process. The method comprises the following steps of: performing down-sampling processing on received sampling data, performing autocorrelation operation at different orthogonal frequency division multiple access symbol intervals in a time domain, performing wireless inter-frame combination and combination of different symbol intervals on an obtained autocorrelation value, judging whether an NPSS exists or not according to the signal-to-noise ratio and the autocorrelation value after merging processing, preliminarily calculating time offset and fractional frequency offset according to the autocorrelation value after merging processing, and judging whether coarse cross-correlation calculation and fine cross-correlation calculation are carried out or not according to a judgment result. Through the method, the operand of calculating the time offset and the frequency offset in the synchronization process can be reduced, and meanwhile, the correct judgment rate for judging whether the NPSS exists or not is improved.

Owner:WUHAN MENGXIN TECH CO LTD

Method and related apparatus for reconfiguring size of a receiving window in a communications system

ActiveUS7852844B2Reduce memory sizeReduce window sizeError prevention/detection by using return channelSynchronising transmission/receiving encryption devicesCommunications systemReal-time computing

A method for reconfiguring size of a receiving window in a communications system avoiding duplicate packet delivery to an upper layer to keep ciphering parameters in synchronization when the communications system reconfigures a receiving window of a receiver includes receiving a command for reconfiguring a size of the receiving window, reconfiguring the size of the receiving window according to the command, removing packets with sequence numbers outside the receiving window from buffers of the receiver and delivering the packets to the upper layer, determining whether a sequence number of a next expected packet is below the receiving window, and keeping the sequence number of the next expected packet and the packets in a reordering buffer of the receiver unchanged when the sequence number of the next expected packet is not below the receiving window.

Owner:INNOVATIVE SONIC

Wireless mobile terminal and telecommunication system

InactiveUS8045465B2Reduce data rateEffect data transmission capacityError prevention/detection by using return channelTransmission systemsTelecommunicationsData rate

A wireless mobile terminal determining a size of an advertised window depending on a current data rate of a wireless downlink transmission is provided. The wireless mobile terminal receives from a transmission control protocol (TCP) sender a data packet comprising a header portion and a payload portion; and determines the current data rate of the wireless downlink transmission to the wireless mobile terminal from signaling information contained in the header portion of the data packet; and determines the size of the advertised window depending on the current data rate of the wireless downlink transmission.

Owner:RPX CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com