Biomass-based carbon material with high specific surface area and its activation-free preparation method and application

A high specific surface area, biomass technology, applied in the field of materials, can solve the problems of unfriendly environment, complicated process, complicated post-treatment process, etc., and achieve the effect of avoiding the use of hydrofluoric acid or strong alkali

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A preparation method of a high specific surface area biomass-based carbon material comprises the following steps:

[0036] (1) Dry 200g of rice husk at 100°C, and then use a pulverizer to grind the rice husk to about 200 mesh;

[0037] (2) In the mortar, successively add 1.1g of polytetrafluoroethylene powder and 0.5g of rice husk powder obtained in step (1), and mix well;

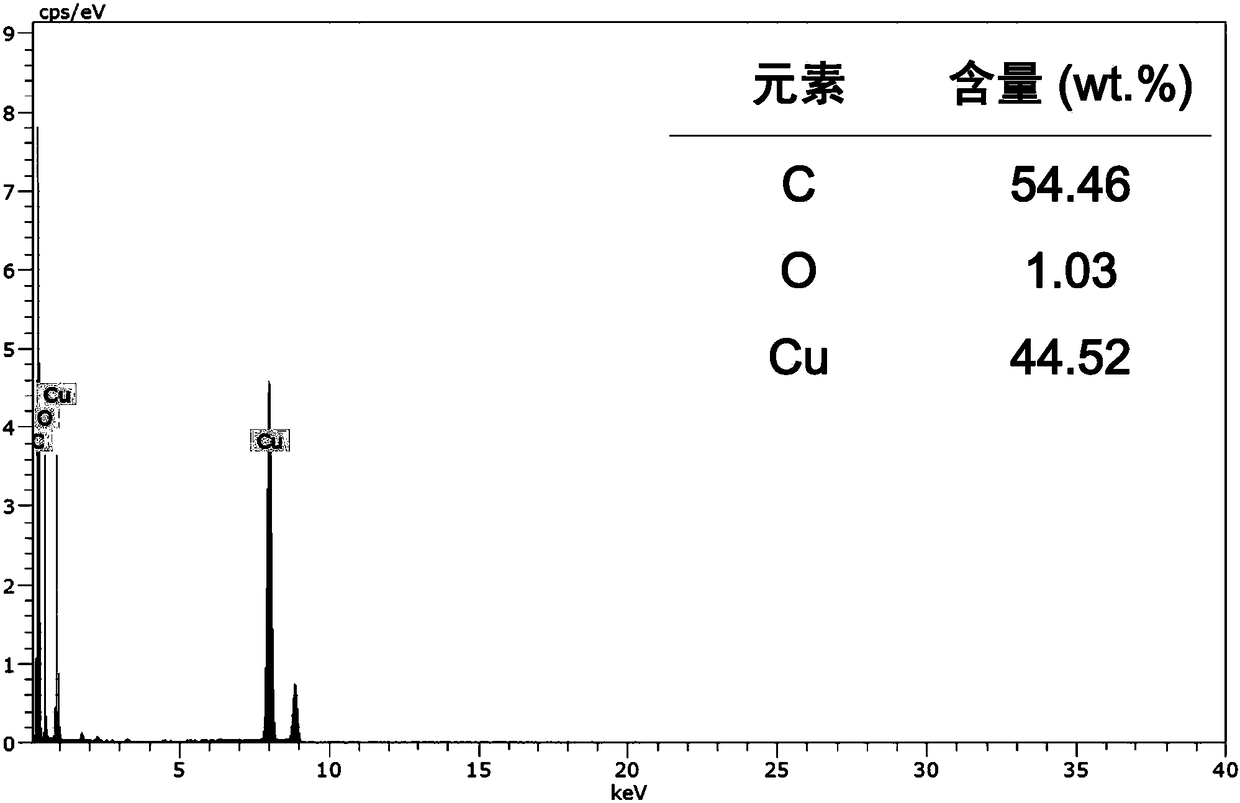

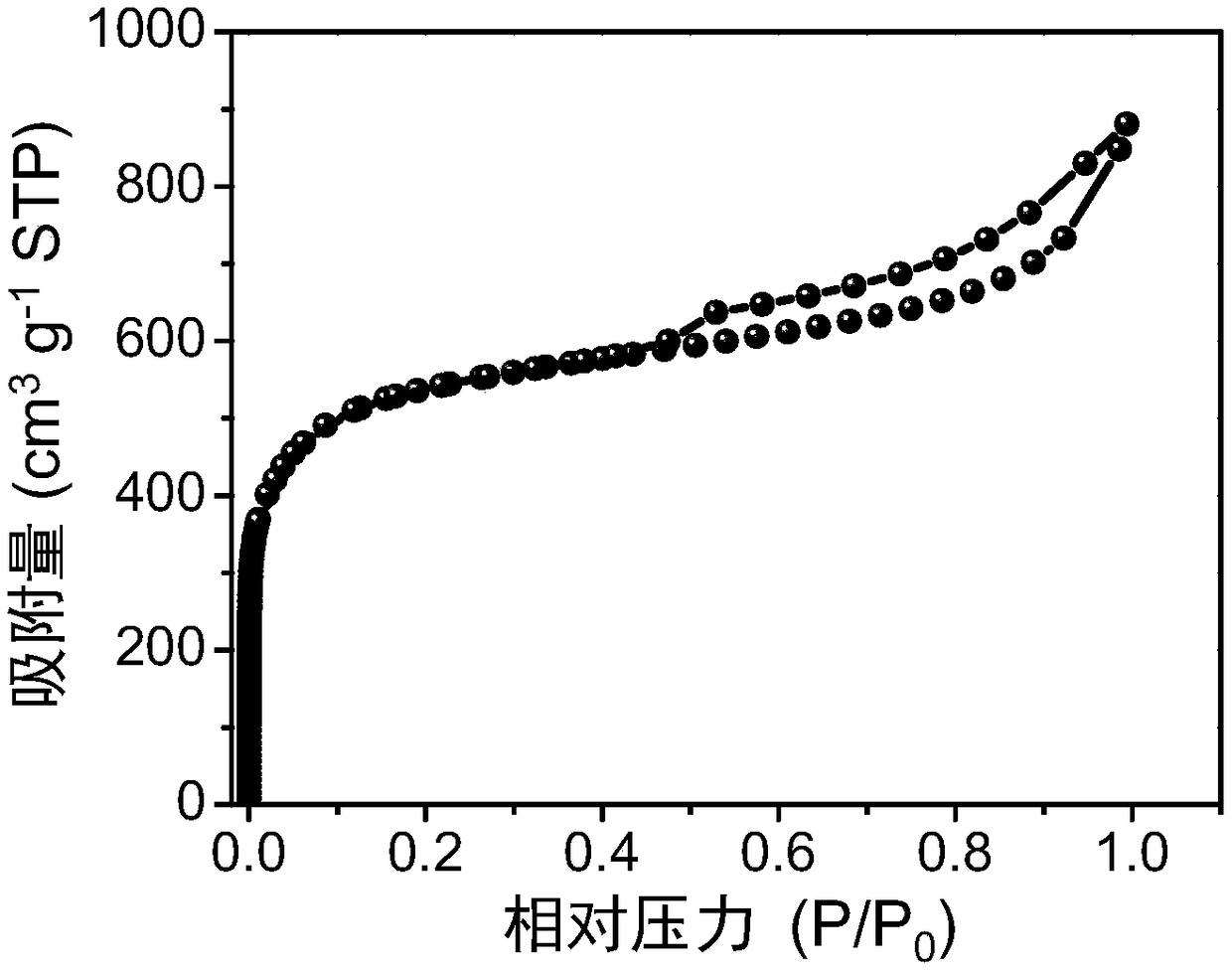

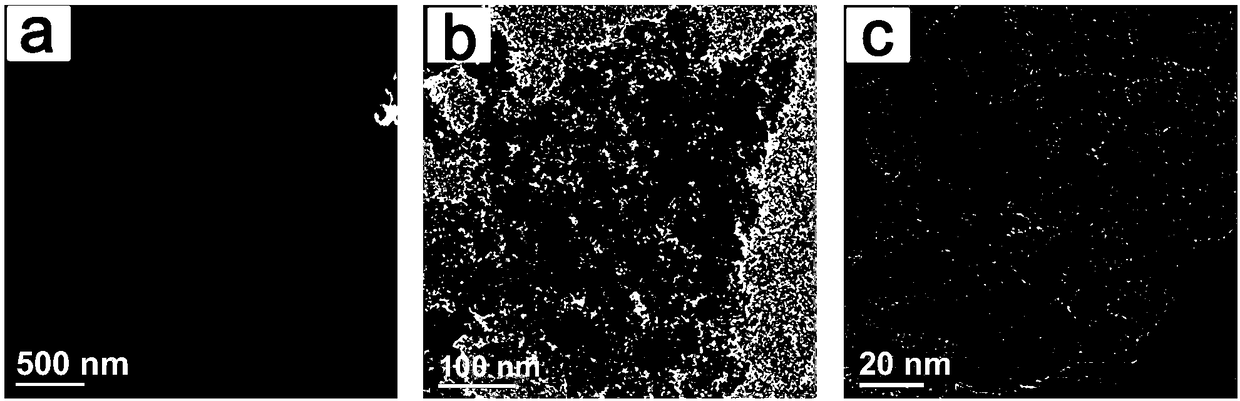

[0038] (3) Heat the rice husk / PTFE mixture obtained in step (2) to 900°C at a heating rate of 5°C / min under a nitrogen atmosphere at a flow rate of 400ml / min, and carbonize at a constant temperature for 4 hours to obtain a high specific surface area Rice husk-based carbon materials. The EDS results and nitrogen adsorption-desorption isotherms of the prepared rice husk-based carbon material with high specific surface area are as follows: figure 1 and figure 2 shown.

[0039]The BET specific surface area of the prepared high specific surface area rice husk-based carbon material is 2051m2 by usi...

Embodiment 2

[0042] A preparation method of a high specific surface area biomass-based carbon material comprises the following steps:

[0043] (1) Dry 200g of rice husk at 100°C, and then use a pulverizer to grind the rice husk to about 200 mesh;

[0044] (2) In the mortar, successively add 1.54g polytetrafluoroethylene powder and 0.7g step (1) obtained rice husk powder, fully mix;

[0045] (3) Heat the rice husk / PTFE mixture obtained in step (2) to 900°C at a rate of 5°C / min under a nitrogen atmosphere at a flow rate of 400ml / min, and carbonize at a constant temperature for 9 hours to obtain a high specific surface area Rice husk-based carbon materials.

[0046] The BET specific surface area of the prepared high specific surface area rice husk-based carbon material is 1427m2 by using the nitrogen adsorption method of the ASAP2020 adsorption instrument produced by Micromeritics Company of the United States. 2 / g, the pore volume is 0.94cm 3 / g.

Embodiment 3

[0048] A preparation method of a high specific surface area biomass-based carbon material comprises the following steps:

[0049] (1) Dry 200g of rice husk at 100°C, and then use a pulverizer to grind the rice husk to about 200 mesh;

[0050] (2) In the mortar, successively add 1.76g polytetrafluoroethylene powder and 0.8g step (1) obtained rice husk powder, fully mix;

[0051] (3) Heat the rice husk / PTFE mixture obtained in step (2) to 900°C at a heating rate of 5°C / min under a nitrogen atmosphere at a flow rate of 400ml / min, and carbonize at a constant temperature for 20 hours to obtain a high specific surface area Rice husk-based carbon materials.

[0052] The BET specific surface area of the prepared high specific surface area rice husk-based carbon material is 1253m3 by using the nitrogen adsorption method of the ASAP2020 adsorption instrument produced by Micromeritics Company of the United States. 2 / g, the pore volume is 0.89cm 3 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com