Electrode pad removal device and hammer

A technology for dismantling devices and electrode pads, which is applied in the direction of hand hammers, resistance welding equipment, multi-purpose hand tools, etc., can solve the problems of shortened overall length and inability to use, etc., to reduce workload, increase operation options, and achieve good efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

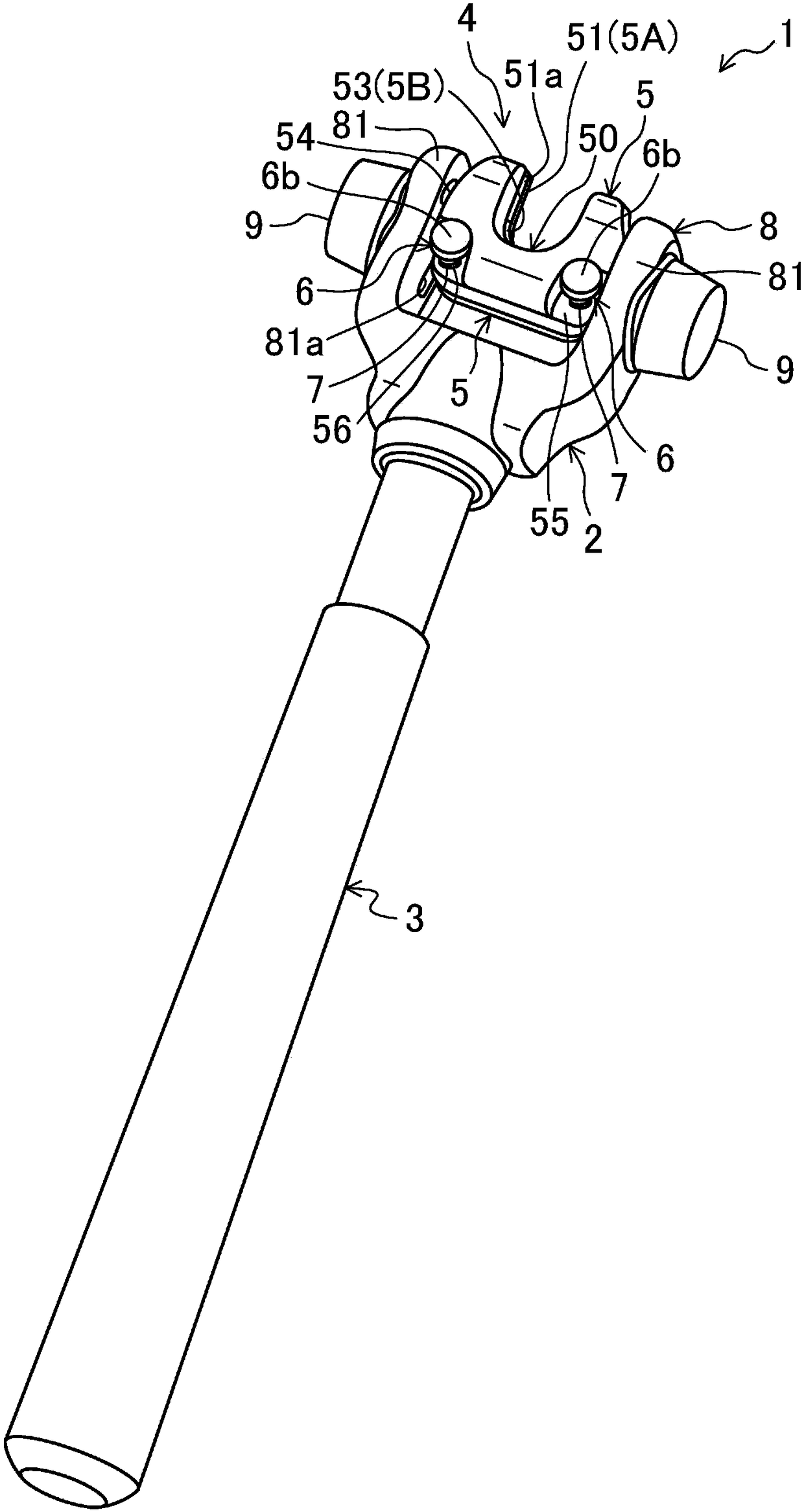

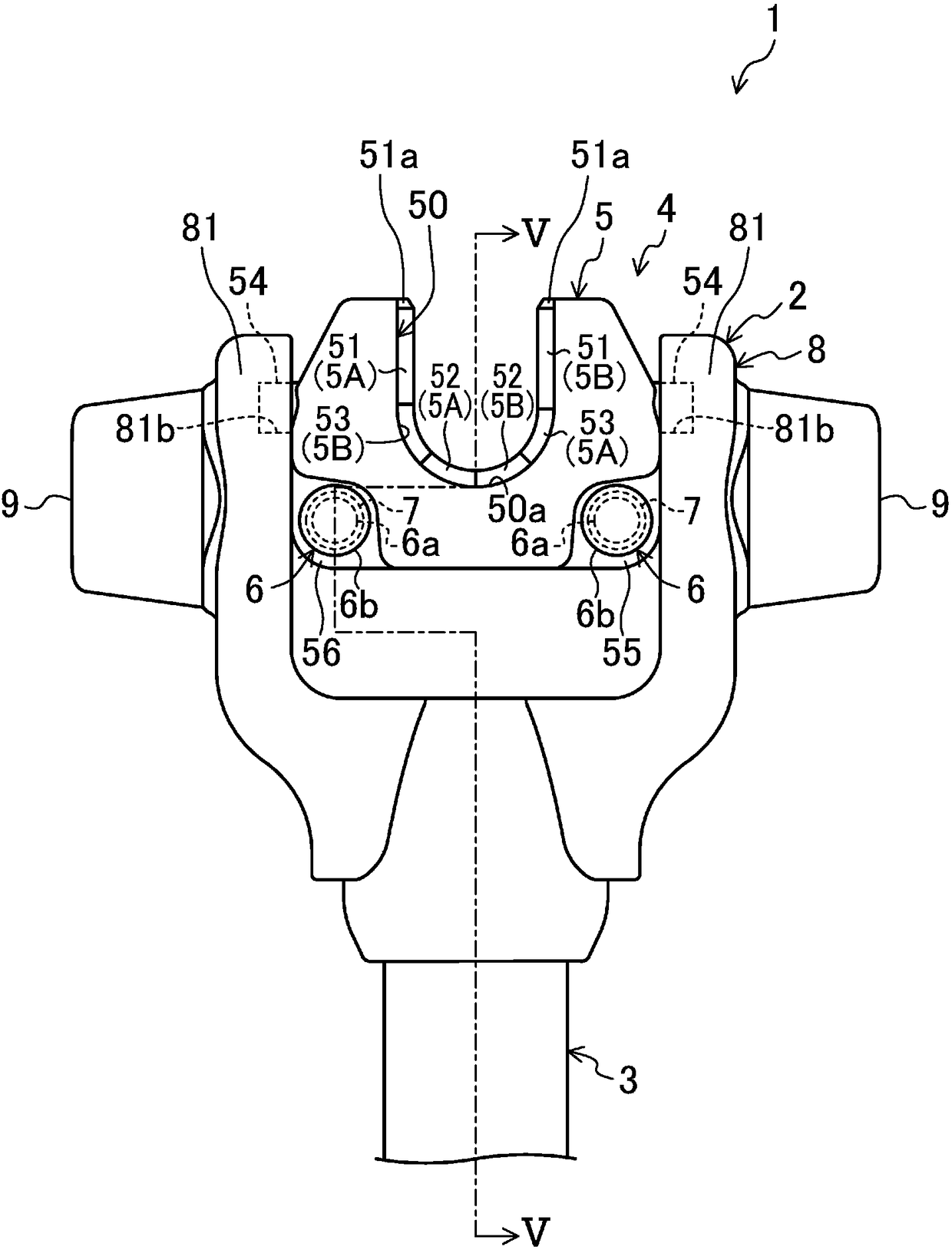

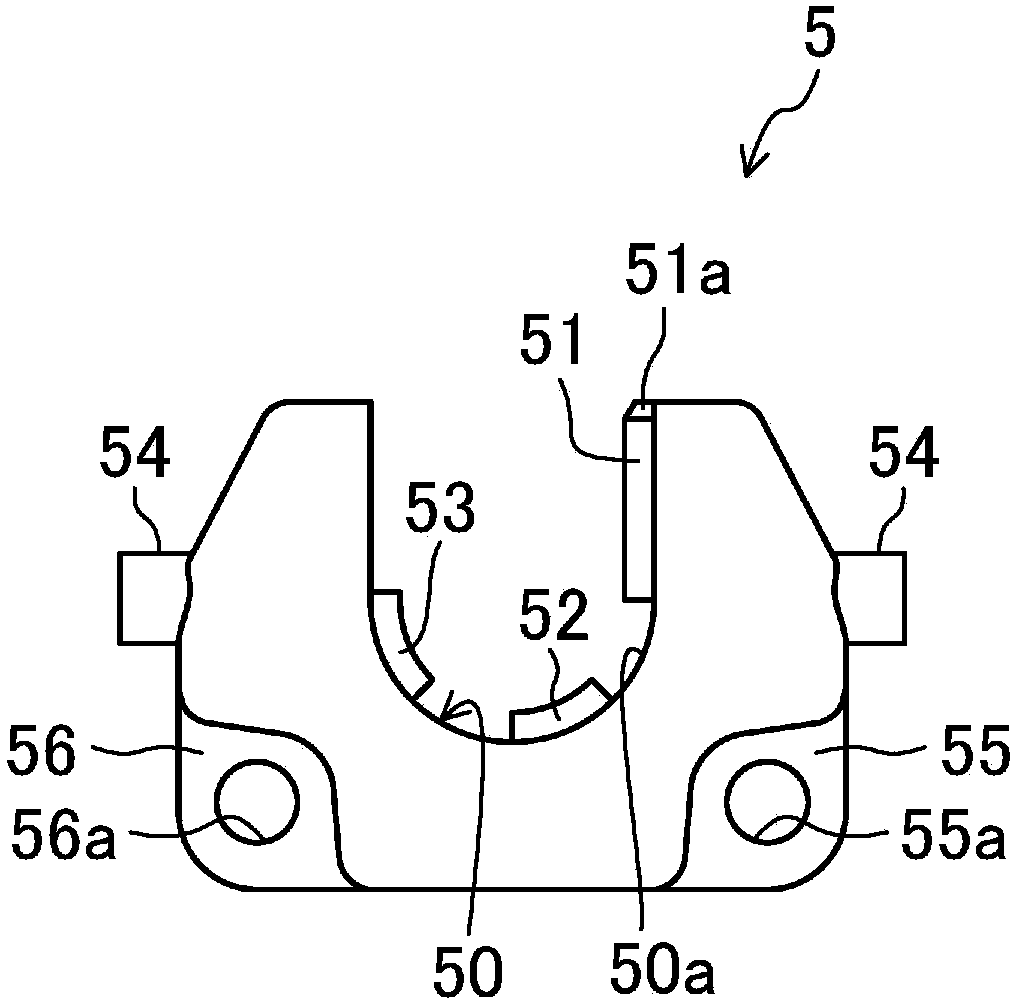

[0045] figure 1 and figure 2 The hammer 1 according to the first embodiment of the present invention is shown. like Figure 5 to Figure 7 As shown, the hammer 1 is used when detaching the electrode pad 12 from the tip of the welding gun 11 for spot welding, or when installing the electrode pad 12 on the tip of the welding gun 11 . The hammer 1 includes a hammer body 2 that is substantially in the shape of a "T" when viewed from above, and an operating rod 3 held by an operator during operation.

[0046] The welding torch 11 is a general welding torch that is held and used by an industrial robot (not shown). A cylindrical large-diameter portion 11 a and a cylindrical small-diameter portion 11 b are formed integrally at the tip of the welding torch 11 so that the central axis 11 c is the same.

[0047] The electrode pad 12 is installed on the small-diameter portion 11b by fitting, so that the central axis 12a of the electrode pad 12 is consistent with the central axis 11c o...

no. 2 approach

[0104] Figure 8 and Figure 9 A hammer 1 according to a second embodiment of the present invention is shown. The second embodiment differs from the first embodiment only in the following two points, and is the same as the first embodiment in other respects. That is, the structure of the second support portion 81b of the arm member 8 is different from the first embodiment, and the point that the hammer 1 is used with the electrode pad 12 of the welding torch 11 facing upward is different from the first embodiment. Therefore, only the differences from the first embodiment will be described in detail below.

[0105] In the second embodiment, the second support portion 81b of each protruding support portion 81 is in the shape of a groove that gradually approaches the side of the one detachable member 5 as it approaches the other end side of the arm member 8, and the second support portion 81b of each protruding support portion 81 The first support portion 81 a and the second s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com