Flexible, open-cell thermoset foams and blowing agents and methods for making same

A thermosetting, foaming agent technology, used in other household appliances, household appliances, household components, etc., to solve problems such as foam splitting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

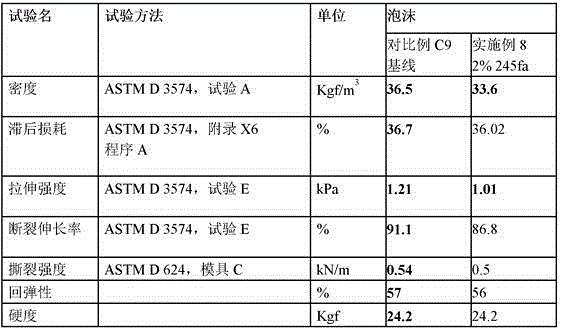

Examples

Embodiment 1

[0109] Open cell flexible polyurethane foam was formed using the same procedure and materials shown above for the control, except that four samples were made and for each sample, the blowing agent was modified to include an amount of hair booster such that the total blowing agent had the following concentration Foaming agent HFCO-1233zd(E), while the total weight of water in the formulation remains constant:

[0110] Foaming agent weight% Mole % water 50.72 88.14 HFCO-1233ZD(E) 49.28 11.86

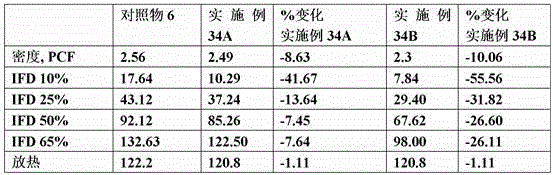

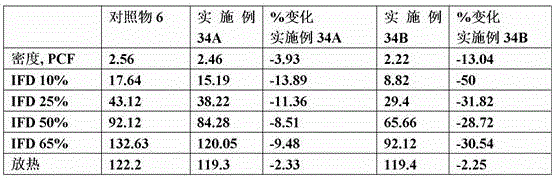

[0111] The foam thus produced was tested and found to have the following average physical properties and comparisons to controls:

[0112] Control Example 1 %Variety Density, PCF 2.23 1.95 -12.4 Compression set (at 45-50°C) 13.969 12.21 -12.6 IFD 25% 125 101 -19.2 IFD 65% 330 250 -24.24 Tensile strength, psi 15.37 13.75 -10.54 Elongation 88.8 101.9 14.75

Embodiment 2

[0114] Open-cell flexible polyurethane foam was formed using the same procedure and materials shown above for the control, except that five samples were made and for each sample, the blowing agent was modified to include HFC-245fa as co-blowing agent in an amount such that HFC -245fa is present in the same molar amount as the co-blowing agent in Example 1 as follows:

[0115] Foaming agent weight% Mole % water 49.96 88.14 HFC-245fa 50.04 11.86

[0116] The foam thus produced was tested and found to have the following average physical properties and comparisons to controls: Control Example 2 %Variety Density, PCF 2.23 1.99 -10.7 Compression set (at 45-50°C) 13.969 14.55 4.13

Embodiment 3

[0118] Open-cell flexible polyurethane foam was formed using the same procedure and materials shown above for the control, except that three samples were made and for each sample, the blowing agent was modified to include HFC-365mfc / HFC227ea as co-blowing agent (at 93 / 7 relative weight ratio) and in an amount such that the co-foaming agent exists in the same molar amount as the co-foaming agent in Example 1 as follows:

[0119] Foaming agent weight% Mole % water 47.21 88.14 HFC-365mfc / 227ea 52.79 11.86

[0120] The foam thus produced was tested and found to have the following average physical properties and comparisons to controls:

[0121] Control Example 3 %Variety Density, PCF 2.23 1.95 -12.6

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| resilience | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com