Fuel feed system to a fuel injector, and fuel injector

A technology of fuel supply device and fuel injector, which is applied in the direction of fuel injection device, charging system, sealing of engine, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

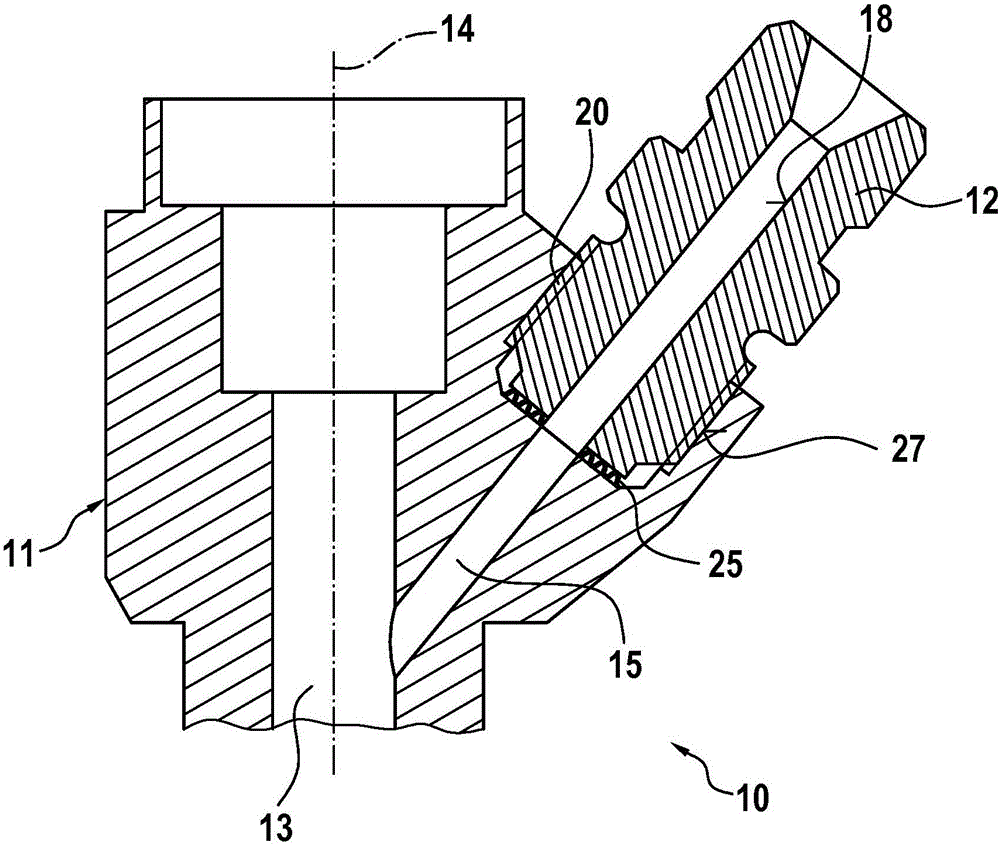

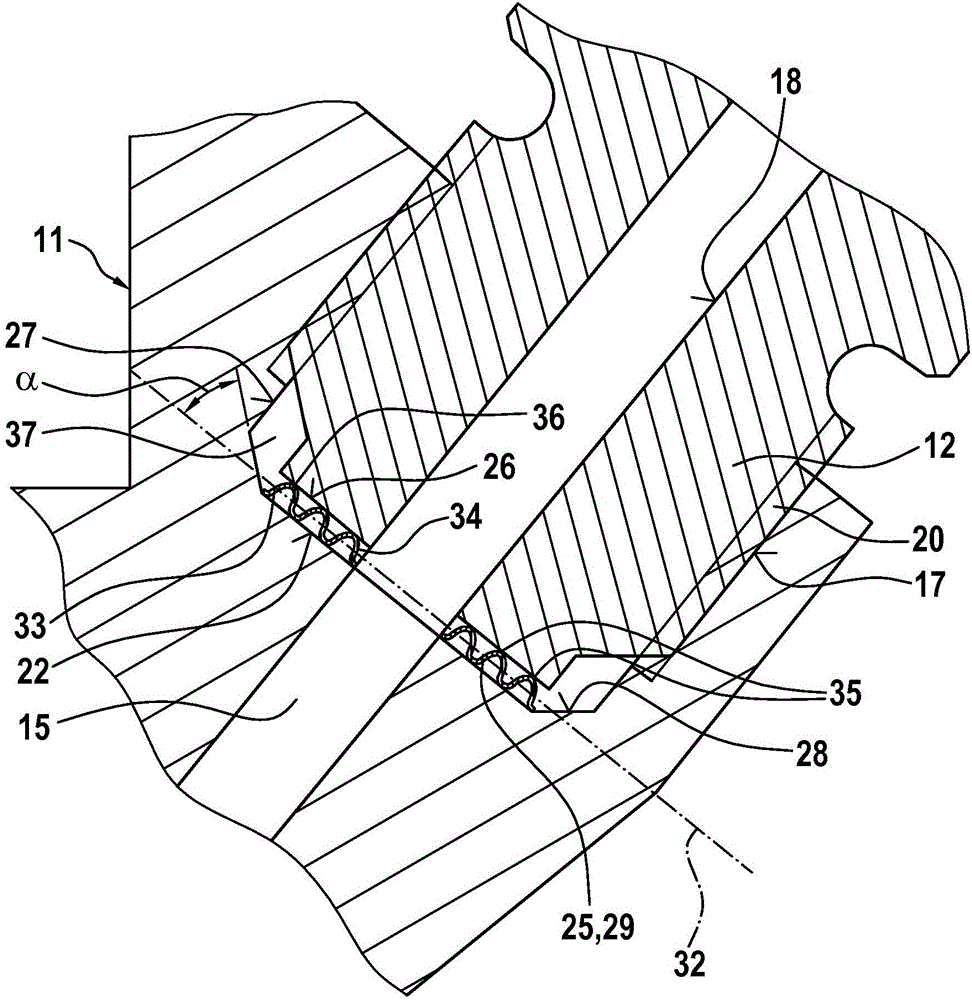

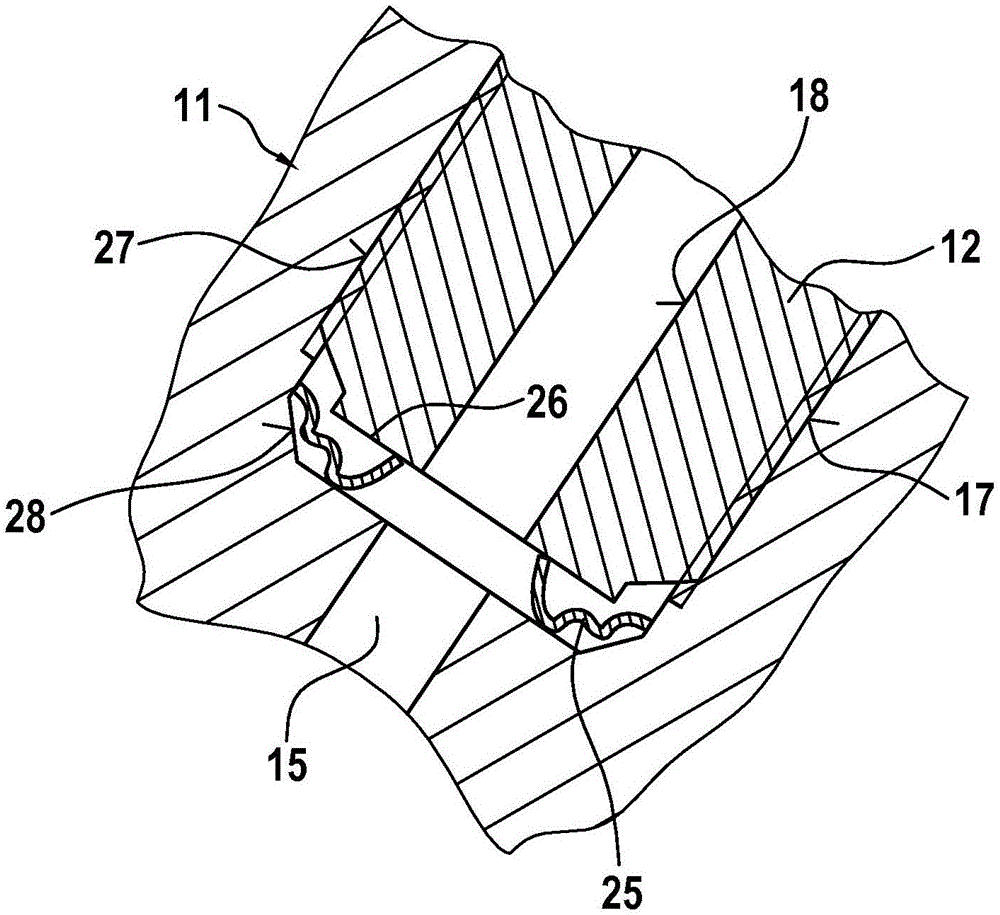

[0019] exist Figures 1 to 3 The connection region according to the invention between the injector housing 11 and the pressure connection 12 of the fuel injector 10 is depicted in . The fuel injector 10 is in particular a so-called common rail injector, which is designed to supply fuel to a combustion chamber of an internal combustion engine (not shown) at system pressures above 2000 bar. For this purpose, the injector housing 11 made of steel has a partly shown high-pressure chamber 13 in which a not-shown nozzle needle arrangement is movable back and forth. By controlling the reciprocating movement of the nozzle needle, the fuel is discharged in the desired manner through at least one injection opening formed in the injector housing 11 into the combustion chamber. The high-pressure chamber 13 is supplied with high-pressure (system pressure) fuel via a supply channel 15 arranged obliquely with respect to the longitudinal axis 14 of the injector housing 11 . For this purpose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com