Method for producing bonded body

A manufacturing method and technology of bonding body, which are applied in the direction of semiconductor/solid-state device manufacturing, semiconductor device, electric solid-state device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

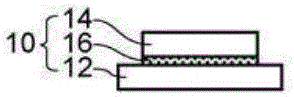

[0040] As shown in FIG. 1 , the method of manufacturing a bonded body according to Embodiment 1 is a method of manufacturing a structure in which a substrate 12 (a substrate on which a conductive circuit pattern is formed) and an electronic component 14 (semiconductor element) are bonded via a metal particle paste 16 . A method of manufacturing a bonded body 11 (semiconductor device) (a method of manufacturing a semiconductor device).

[0041] Next, the substrate 12, the electronic component 14, and the metal particle paste 16 will be described in detail.

[0042] The "substrate" in the present invention refers to a component on which electronic components are mounted.

[0043]Electronic components 14 are mounted on the substrate 12 . The substrate 12 in Embodiment 1 is, for example, a circuit substrate in which a conductive circuit pattern is formed on a body made of a non-conductive material. As the constituent material of the substrate 12, a material (for example, a heat-...

Embodiment approach 2

[0065]The method of manufacturing the joined body in Embodiment 2 basically includes the same steps as the method of manufacturing the joined body in Embodiment 1, but it differs from the method of manufacturing the joined body in Embodiment 1 in that it does not utilize two The sheet heating plate directly pressurizes and heats the assembly to join the substrate and the electronic component, but indirectly presses and heats the assembly using a pressing unit to join the substrate and the electronic component. That is, the manufacturing method of the bonded body in Embodiment 2, as shown in FIG. 5 , between the assembly forming step and the assembly arranging step, further includes: a pressurizing unit forming step, so as to utilize the two functions of conducting pressure and heat. The sheet conduction members (first conduction member 210, second conduction member 220) sandwich the assembly to form a press unit 200 (see FIG. 5(a)), which is characterized in that: In the proce...

Embodiment approach 3

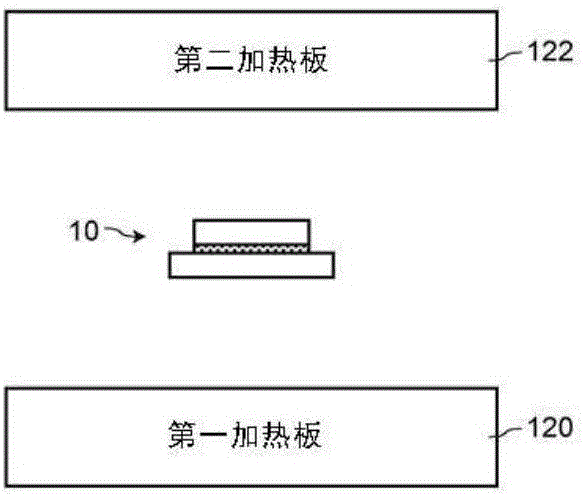

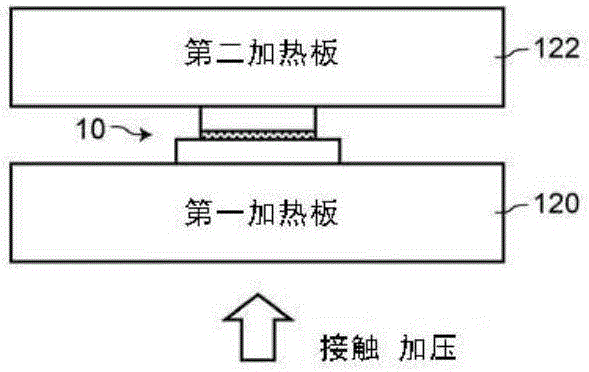

[0098] The method of manufacturing a joined body according to Embodiment 3 basically includes the same steps as the method of manufacturing a joined body in Embodiment 1, but it differs from the method of manufacturing a joined body in Embodiment 1 in that the first heating plate The temperature and the content of the assembly configuration process. That is, in the method for manufacturing a bonded body according to the third embodiment, the temperature of the first heating plate 120 among the two heating plates is set in the range of 50° C. to 150° C. (for example, 100° C.), and the two heating plates are The temperature of the second heating plate 122 among the heating plates is set in the range of 250° C. to 350° C. (for example, 300° C.), and, in the assembly disposing process, the assembly 10 is arranged on the same side as the first heating plate 120 . contact position (refer to Figure 11).

[0099] In this way, the method of manufacturing a bonded body according to the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com