Quadrangular cell case for vehicle cell and method for manufacturing same

A prismatic battery, vehicle battery technology, applied in small-sized batteries/battery packs, large-sized batteries/battery packs, batteries, etc., can solve the problems of unstable sealing welding and unstable weld bead shape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the drawings. In addition, in this specification and drawing, the same code|symbol is attached|subjected to the component which has substantially the same functional structure, and repeated description is abbreviate|omitted.

[0034] The basic structure of the square battery case:

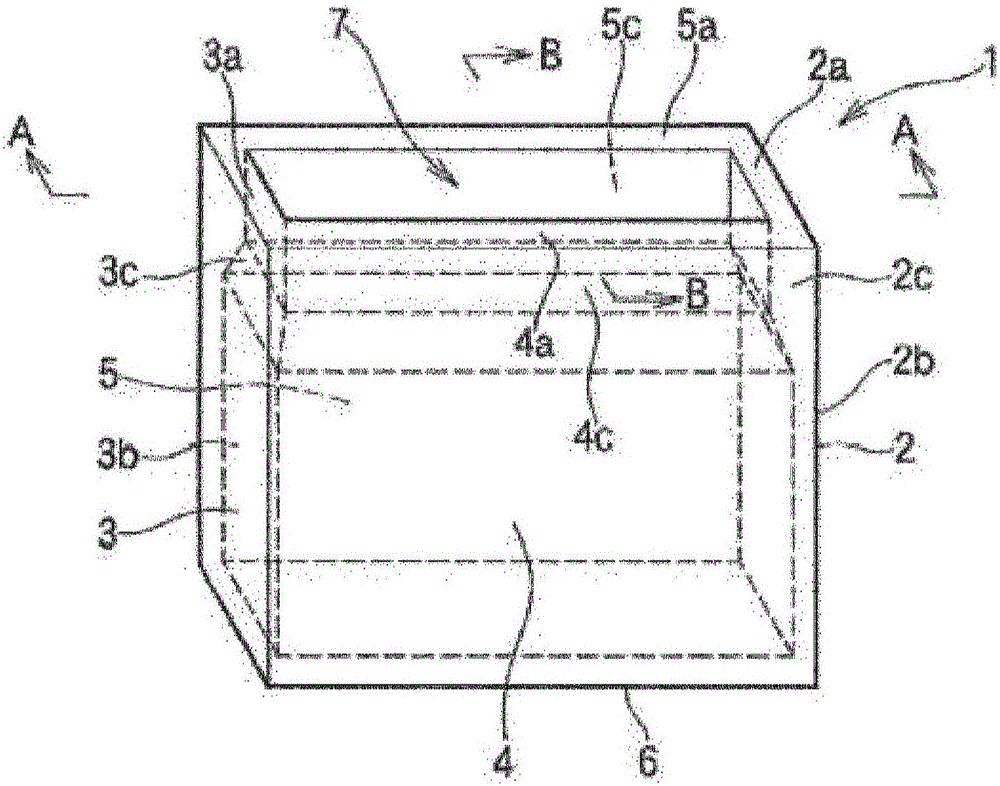

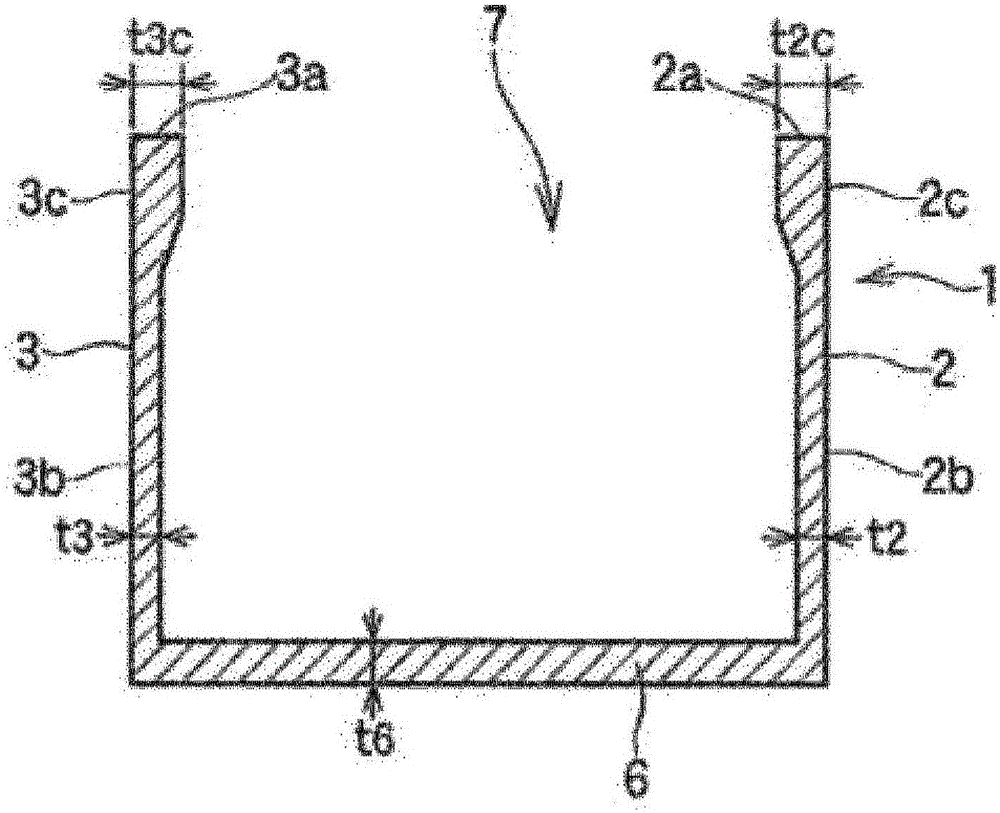

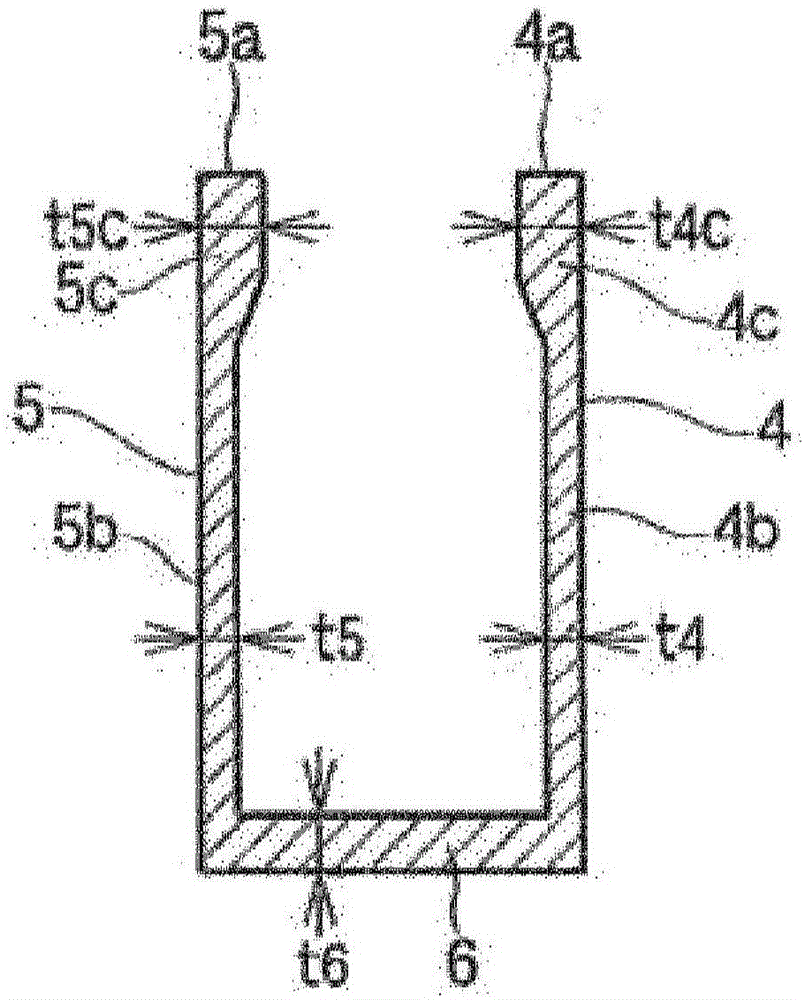

[0035] Figure 1~3 One form of the prismatic battery case of the present invention is shown. The term “prismatic battery case” in the present invention refers to a battery case made of aluminum alloy that has a bottom, a side wall, and an opening, and has a rectangular cross-sectional shape.

[0036] exist Figure 1~3 In, as a premise, the rectangular battery case 1 is used as an on-vehicle battery. That is, a plurality of battery cases 1 are arranged side by side and assembled into a module for use. Therefore, in terms of space efficiency, a flat and thin aluminum alloy battery cas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com