A kind of preparation method of nano silver wire

A nano-silver wire and nano-fiber technology, used in nanotechnology, filament/wire forming, textiles and papermaking, etc., can solve the problem of flexible optoelectronic materials with poor resistance uniformity and bending, long equipment process, and nano-silver wire. Poor uniformity and other problems, to achieve the effect of being conducive to stable implementation, good spinnability and good shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1. Preparation of spinning solution

[0035] Dissolve analytically pure silver nitrate in pure water, stir and mix, and prepare a silver nitrate solution with a concentration of 30% by mass;

[0036] Take 100ml of the above silver nitrate solution, add 5g of polyvinylpyrrolidone with a weight average molecular weight of 80,000 to it, stir, after the polyvinylpyrrolidone is dissolved, add butyl titanate with a volume ratio of 1:1 to the silver nitrate solution 4ml of the mixed solution with acetylacetone, continue to stir until the ingredients are fully dissolved and mixed, and then stand still until the bubbles disappear completely to prepare a spinning solution.

[0037] 2. Preparation of nanofibers

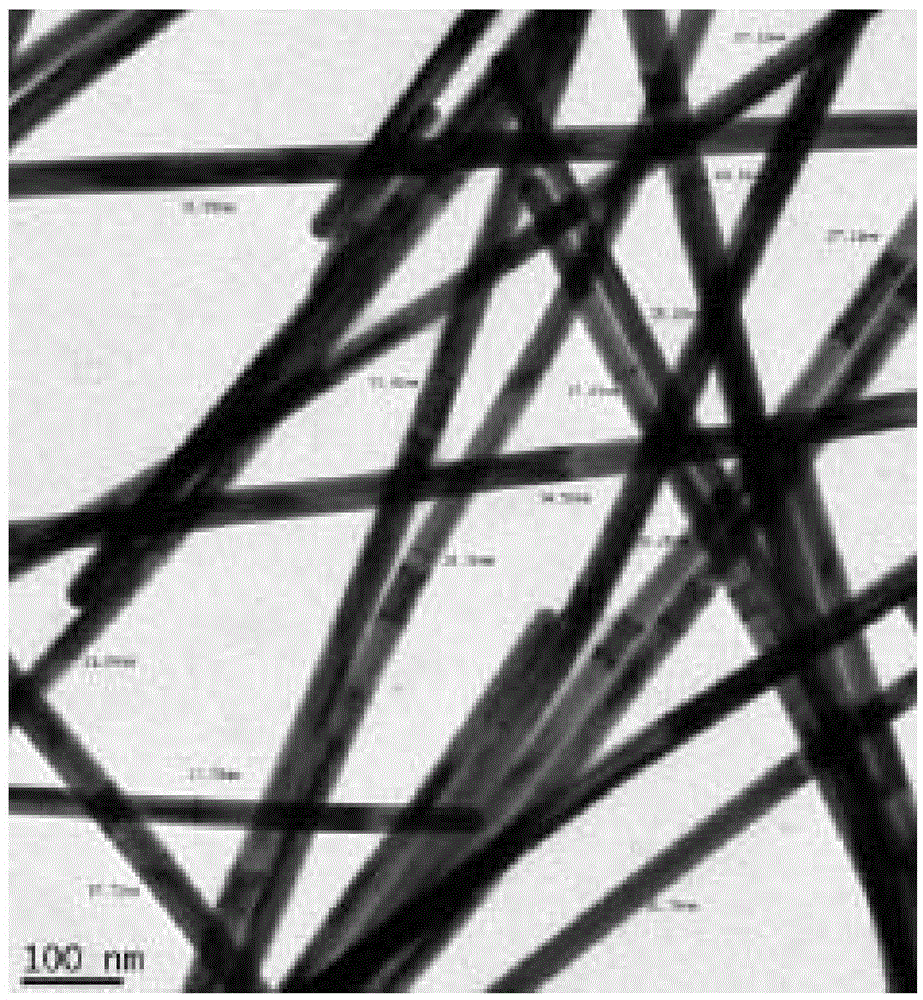

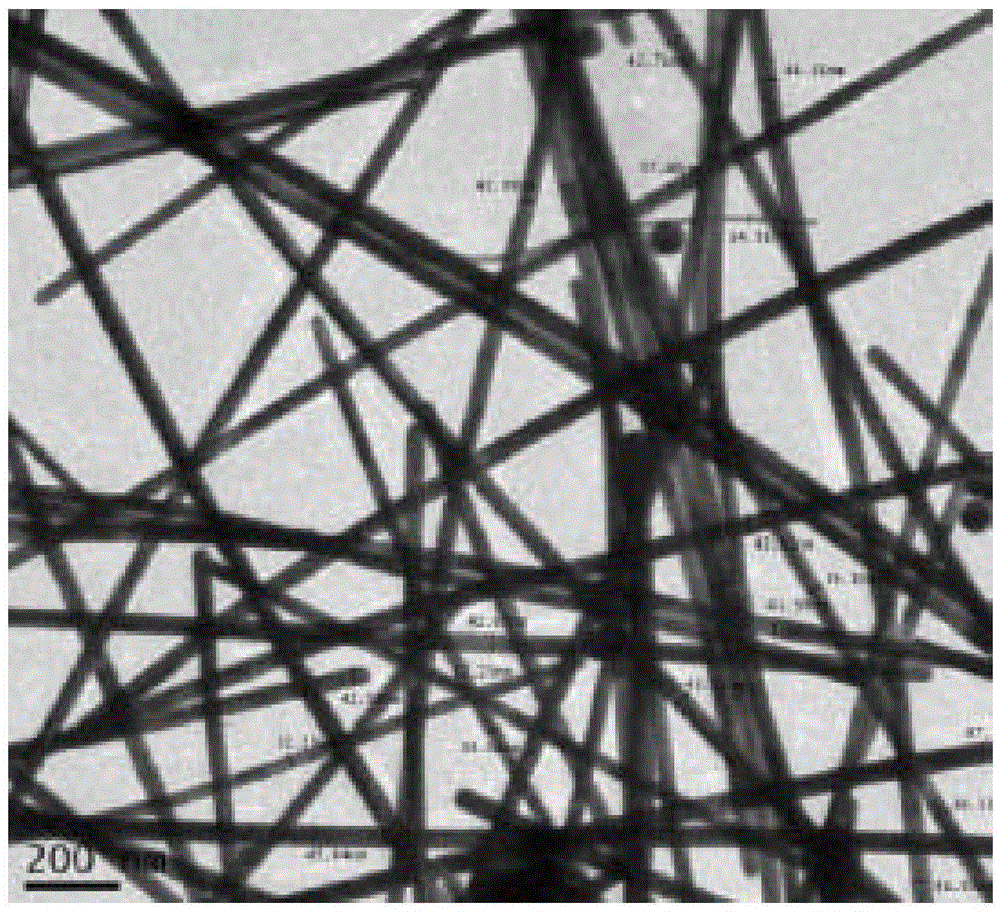

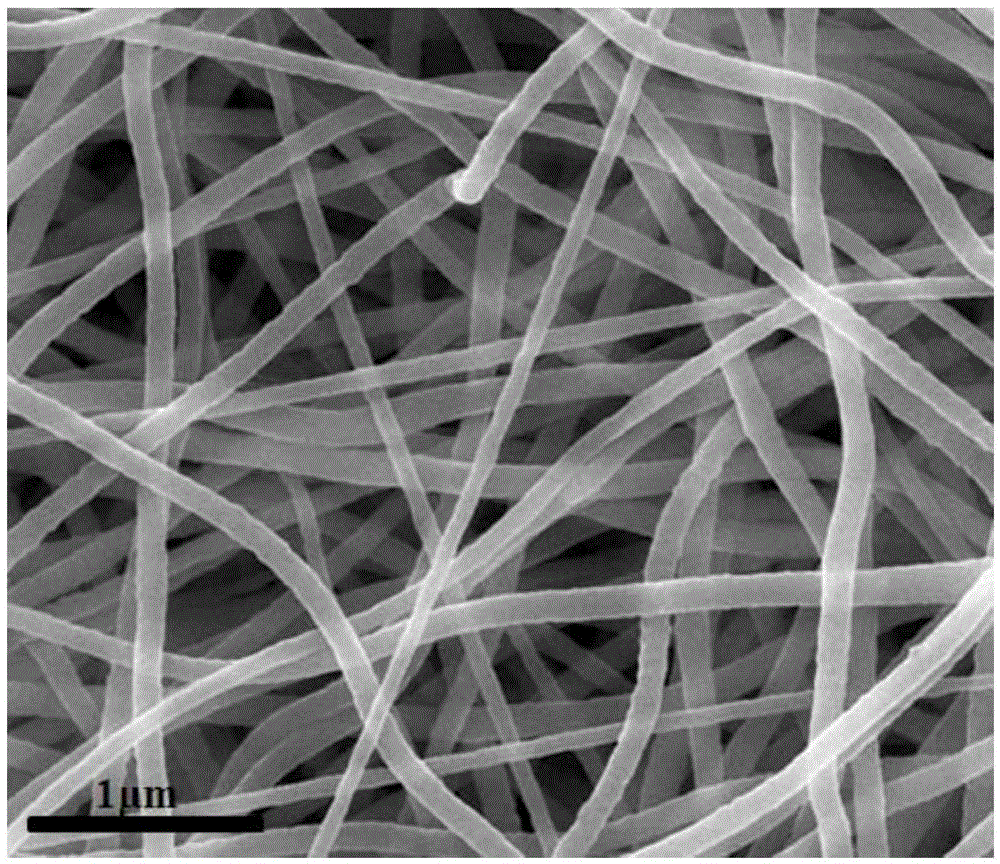

[0038] Add the above-mentioned spinning solution to the feeding device of the electrospinning equipment, set the spinning voltage to 15kV, the feeding rate of the spinning solution (that is, the spinning rate) to 20ul / min, and the receiving distance to 8cm for electrostatic spinn...

Embodiment 2

[0043] 1. Preparation of spinning solution

[0044] Dissolve analytically pure silver nitrate in pure water, stir and mix, and prepare a silver nitrate solution with a concentration of 30% by mass;

[0045] Take 100ml of the above silver nitrate solution, add 10g of polyvinylpyrrolidone with a weight average molecular weight of 100,000 to it, stir, and after the polyvinylpyrrolidone is dissolved, add butyl titanate with a volume ratio of 1:2 to the silver nitrate solution Mix 6 ml of the mixed solution with acetylacetone, continue to stir until the ingredients are fully dissolved and mixed, and then stand still until the bubbles disappear completely to prepare a spinning solution.

[0046] 2. Preparation of nanofibers

[0047] Add the above-mentioned spinning solution to the feeding device of the electrospinning equipment, set the spinning voltage to 17kV, the feeding rate of the spinning solution to be 30ul / min, and the receiving distance to be 13cm, and perform electrospinning to ob...

Embodiment 3

[0051] 1. Preparation of spinning solution

[0052] Dissolve analytically pure silver nitrate in pure water, stir and mix, and prepare a silver nitrate solution with a concentration of 35% by mass;

[0053] Take 100ml of the silver nitrate solution, add 3g of polyvinylpyrrolidone with a weight average molecular weight of 500,000 to it, stir, and after the polyvinylpyrrolidone is dissolved, add butyl titanate with a volume ratio of 1:1 to the silver nitrate solution Mix 6 ml of the mixed solution with acetylacetone, continue to stir until the ingredients are fully dissolved and mixed, and then stand still until the bubbles disappear completely to prepare a spinning solution.

[0054] 2. Preparation of nanofibers

[0055] Add the above-mentioned spinning solution to the feeding device of the electrospinning equipment, set the spinning voltage to 10kV, the feeding rate of the spinning solution to 60ul / min, and the receiving distance to be 5cm. Electrospinning is performed to obtain nanof...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com