AC motor drive system

A technology of AC motor and drive system, which is applied in the direction of AC motor control, DC motor deceleration device, motor generator control, etc. It can solve the problems of DC bus voltage drop and DC bus voltage rise, and achieve reliable power regeneration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

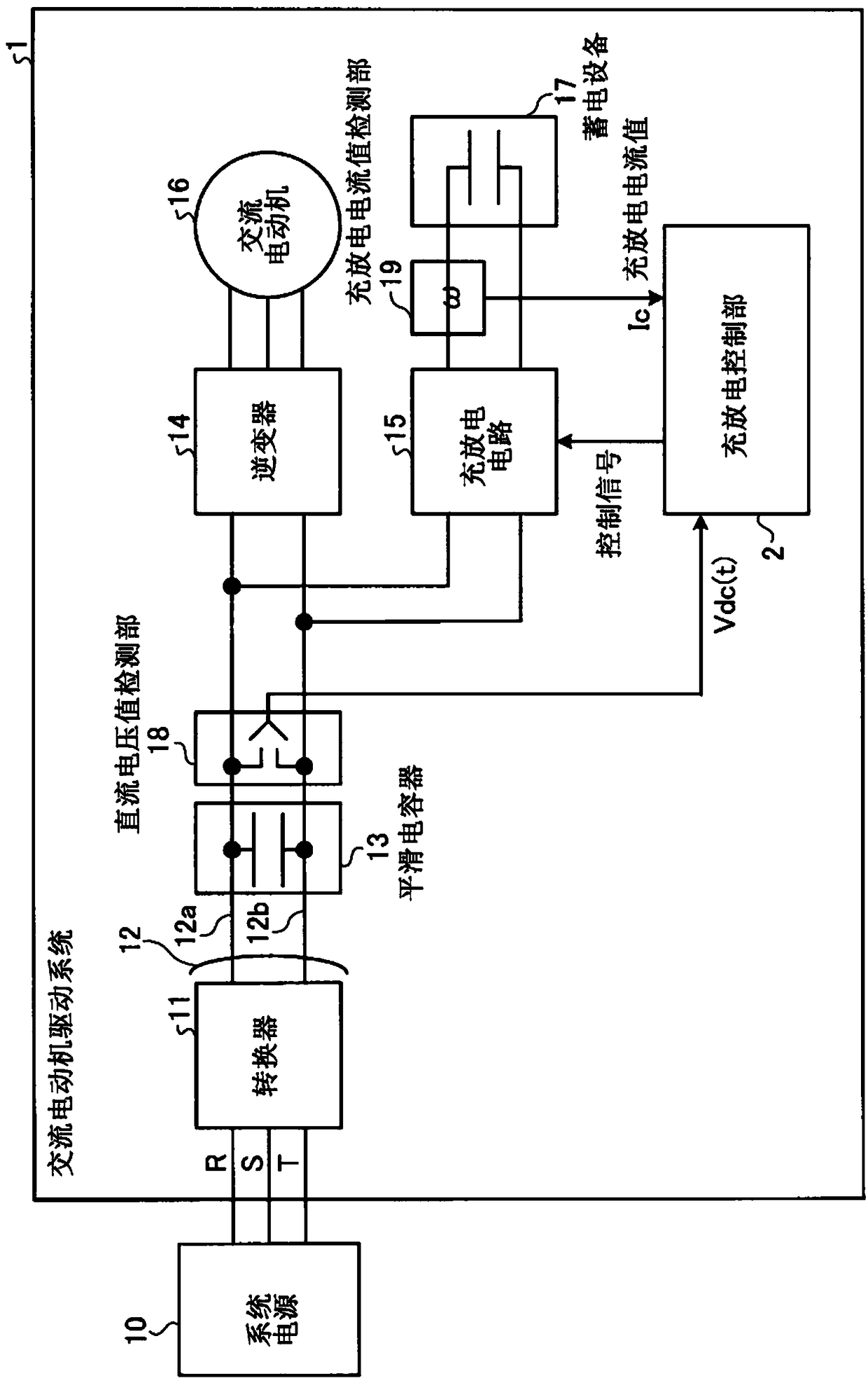

[0031] figure 1 It is a block diagram showing the overall configuration of Embodiment 1 of the AC motor drive system according to the present invention. figure 1 The illustrated AC motor drive system 1 includes a charge and discharge control unit 2, a converter 11, a DC bus 12, a smoothing capacitor 13, an inverter 14, a charge and discharge circuit 15, an AC motor 16, an electrical storage device 17, and a DC voltage value detection unit. part 18 and charge and discharge current value detection part 19. Towards figure 1The illustrated AC motor drive system 1 is supplied with AC power from a system power source 10 such as a power plant or a substation facility in a factory via wiring lines R, S, and T. Converter 11 converts AC power from system power supply 10 into DC power. The converted DC power is output from the converter 11 to the DC bus 12 . Furthermore, the DC bus 12 has a high potential side DC bus 12a and a low potential side DC bus 12b. The smoothing capacitor 1...

Embodiment approach 2

[0087] Figure 14 It is a block diagram showing the overall configuration of Embodiment 2 of the AC motor drive system according to the present invention. Figure 14 The illustrated AC motor drive system 1a includes a charge and discharge control unit 2a, a converter 11a, a DC bus 12, a smoothing capacitor 13, an inverter 14, a charge and discharge circuit 15, an AC motor 16, an electrical storage device 17, a DC voltage value detection part 18 and charge and discharge current value detection part 19. Converter 11a outputs regeneration period flag Fd to charge / discharge control unit 2a. The regeneration period flag Fd is a signal indicating that it is valid only while the converter 11 a is regenerating electric power from the DC bus 12 to the system power supply 10 . The regeneration period flag Fd is not valid when there is no load or when the converter 11a is supplying electric power from the system power supply 10 to the DC bus 12 . Figure 14 The AC motor drive system 1...

Embodiment approach 3

[0095] Figure 16 It is a block diagram showing the overall configuration of Embodiment 3 of the AC motor drive system according to the present invention. Figure 16 The shown AC motor drive system 1b includes a charge and discharge control unit 2b, an AC voltage value detection unit 8, a converter 11, a DC bus 12, a smoothing capacitor 13, an inverter 14, a charge and discharge circuit 15, an AC motor 16, a power storage Device 17 , DC voltage value detection unit 18 and charge and discharge current value detection unit 19 . Figure 16 The AC motor drive system 1b of the present embodiment shown and figure 1 The AC motor drive system 1 of Embodiment 1 shown differs in the presence of the AC voltage value detection unit 8 and the charge / discharge control unit 2 b which inputs the AC voltage value Vac which is the output of the AC voltage value detection unit 8 . The AC voltage value detection unit 8 is connected to the system power supply 10 side of the converter 11, detects...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com