Method and system for reducing particulate emissions

A particulate filter and engine system technology, applied in the direction of electronic control of exhaust treatment devices, diagnostic devices of exhaust treatment devices, exhaust devices, etc., can solve the problem that the temperature of particulate filters cannot reach a high enough temperature and reduce fuel consumption. Economy, increase filter temperature and other issues, achieve the effect of maintaining fuel economy, improving reliability, and maintaining PM emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

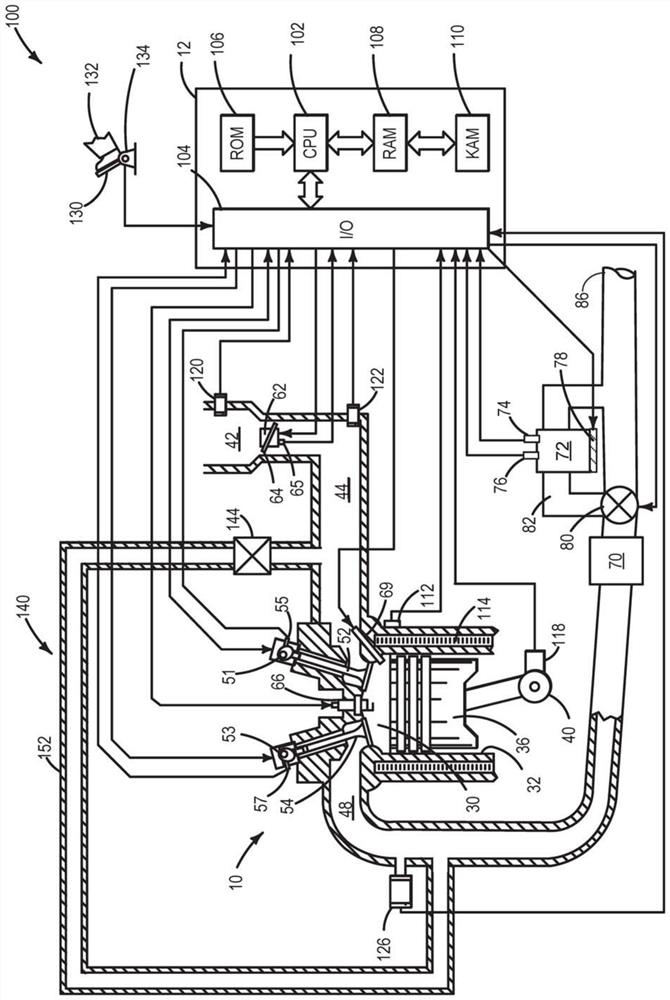

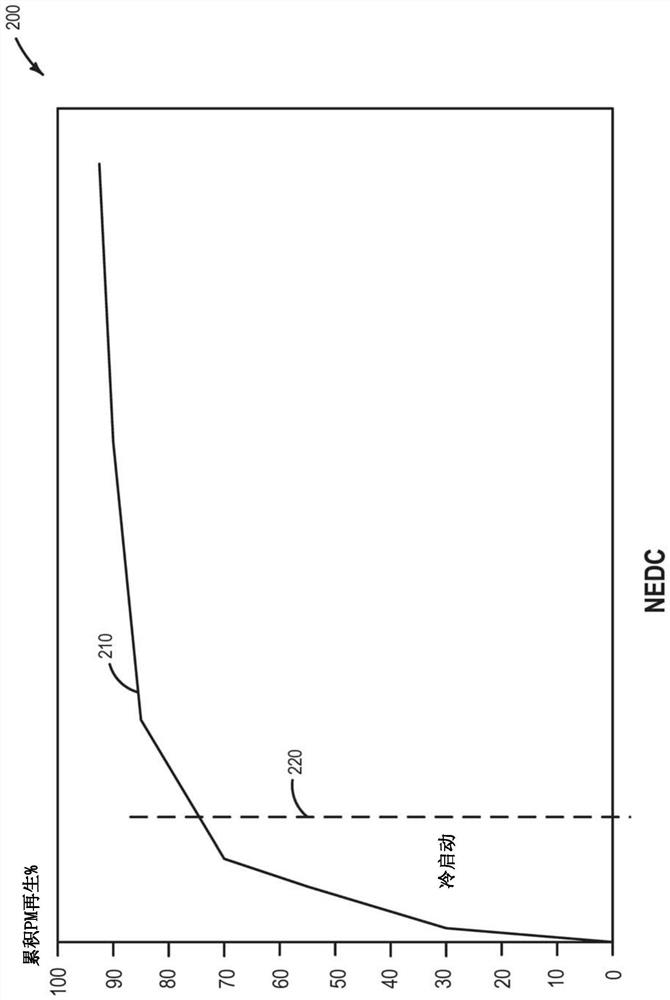

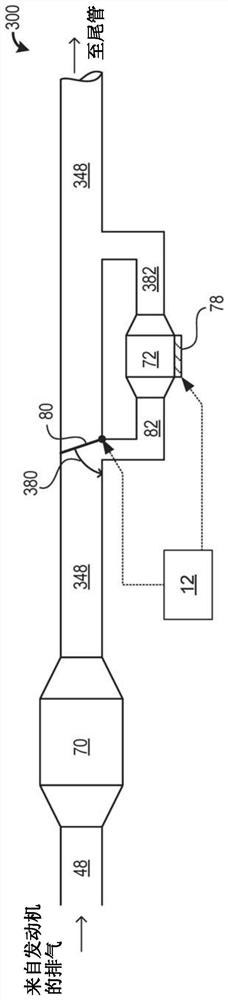

[0014] The following description relates to systems and methods for reducing particulate emissions from an engine system including an exhaust reversing valve and an exhaust particulate filter. figure 1 A vehicle engine system including an exhaust particulate filter is shown in , which may be configured to operate on a fuel such as diesel or gasoline. The exhaust particulate filter may include a diesel particulate filter (DPF), a gasoline particulate filter (GPF), and the like to filter particulate matter (PM) in engine exhaust. Exhaust particulate filters trap PM during vehicle driving such as figure 2 shown in the graph in. Such as Figure 3 to Figure 4 As shown in , exhaust gas may be directed via an exhaust reversing valve in the main exhaust passage to an exhaust particulate filter disposed in the bypass exhaust passage. Figure 5 A method for operating an engine system including an exhaust reversing valve for directing exhaust gas to an exhaust particulate filter is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com