Method for operating a brushed commutator motor of a regulating drive and regulating drive

A driving device and motor technology, applied in the direction of DC motor speed/torque control, motor control, power steering mechanism, etc., can solve the problems of adverse auditory impression load and load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] specific implementation plan

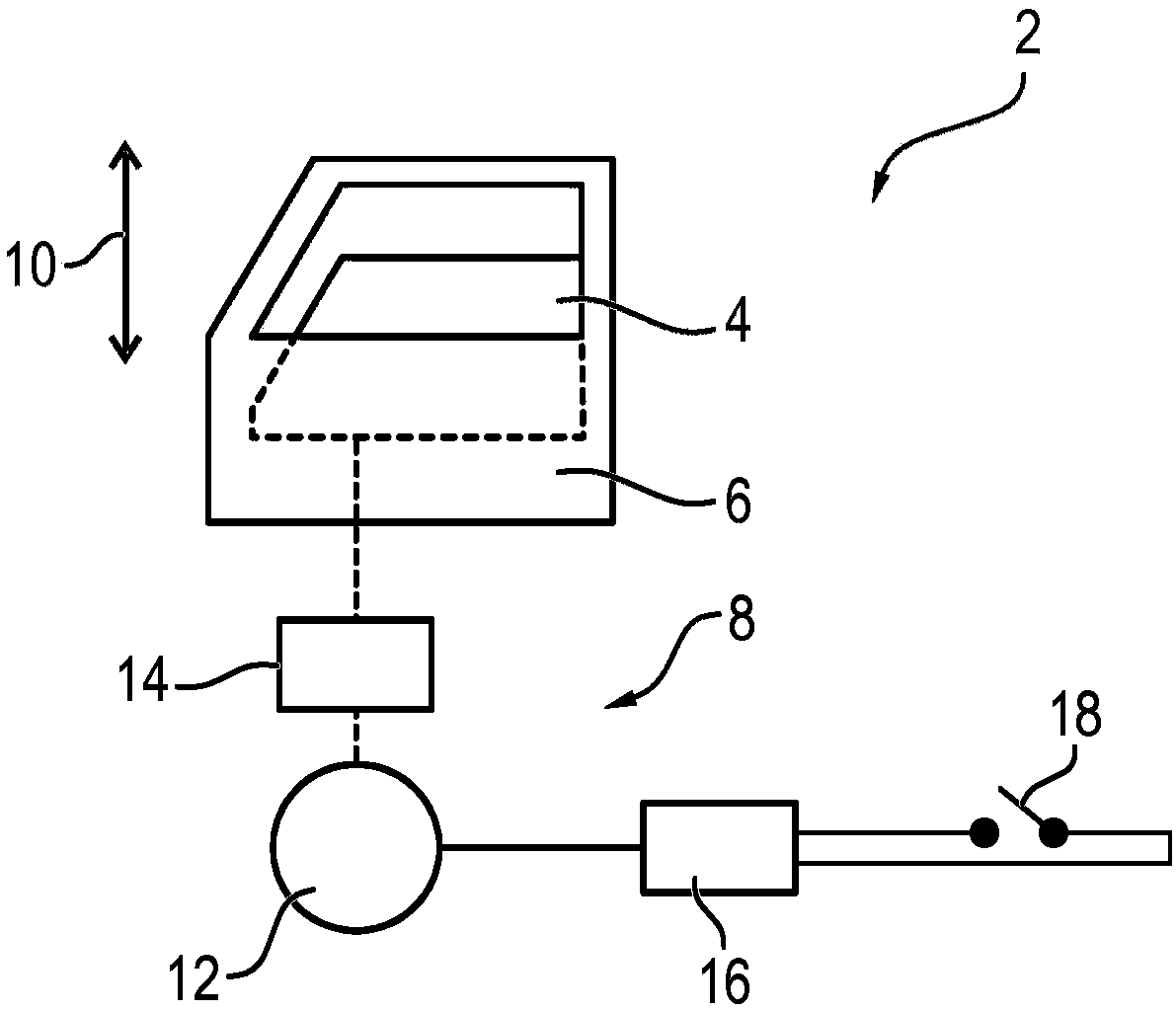

[0033] figure 1 An electric window regulator 2 is shown schematically with a window pane 4 , wherein the window regulator 2 is integrated in a door 6 of a motor vehicle. The window pane 4 is advanced along an adjustment path 10 by means of an adjustment drive 8 . The adjusting drive 8 includes an electric motor 12 , to which a worm gear 14 is assigned on the shaft side, by means of which the rotational movement of the electric motor 12 is converted into a translation of the window pane 4 . As soon as the motor vehicle occupant initiates the adjustment movement of the window pane 4 along the adjustment path 10 using the operating button 18 , the electric motor 12 is powered by the motor electronics 16 . Also integrated in the motor electronics 16 (also referred to as control electronics) is an anti-pinch protection which prevents the windshield 4 from pinching objects lying within the adjustment path 10 .

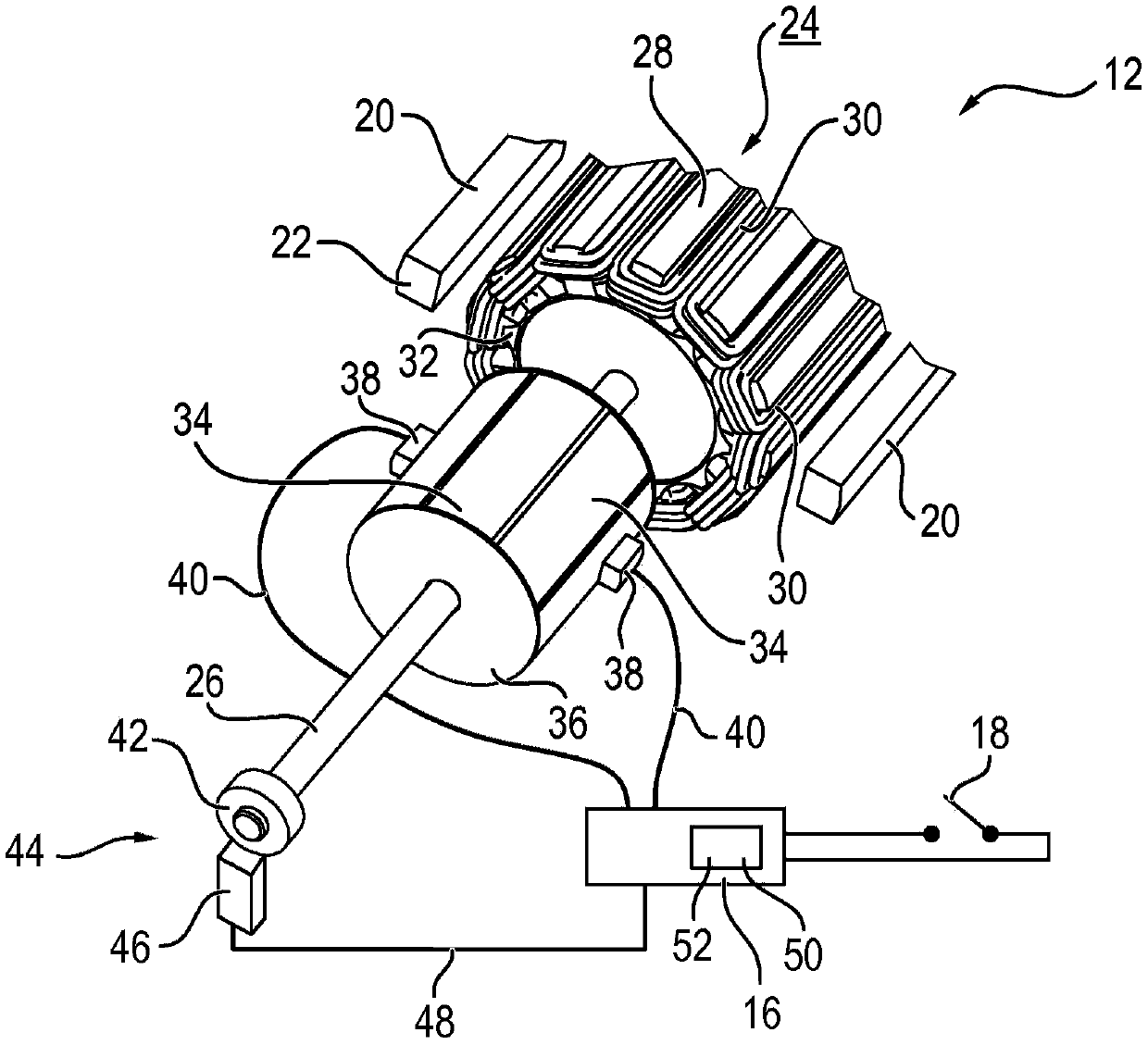

[0034] figure 2 An electric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com