Method for preparing freeze-drying excipients of any shape by utilizing multiple molds and product made thereby

A freeze-dried excipient and arbitrary-shaped technology, which is applied in the field of freeze-dried excipients, can solve the problems of single preparation structure, inaccurate drug dosage, and difficulty in preparing freeze-dried excipients.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

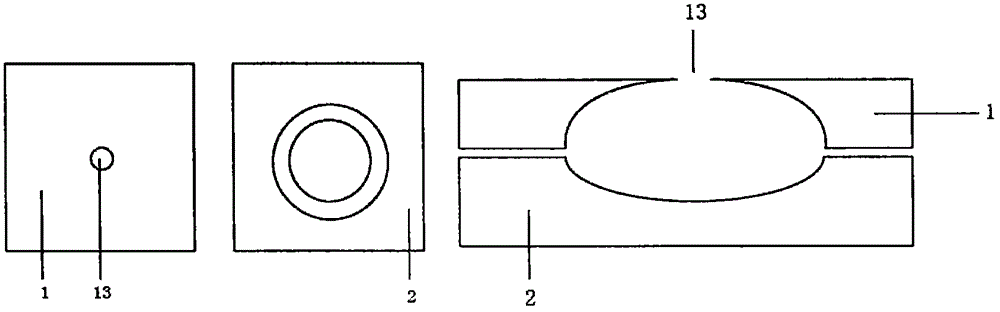

[0086] (a) Take a mold assembly consisting of 2 parts that can produce tablets without sharp edges, and pre-cool it to -40°C;

[0087] (b) adding bilberry extract: pullulan = 5:1, adding water to prepare a solution, centrifuging and degassing, to obtain a stock solution of freeze-dried excipient preparation;

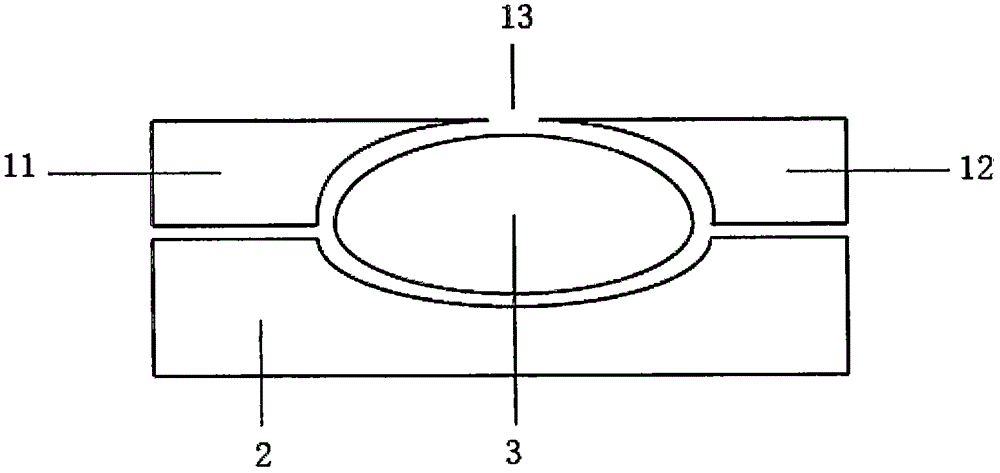

[0088] (c) using a pipette pump to slowly inject the stock solution of the freeze-dried excipient preparation from the mold filling hole 13 into the mold for filling;

[0089] (d) After the stock solution of the freeze-dried excipient preparation is frozen and solidified, open the mold to take it out and place it on a tray;

[0090] (e) Freeze-drying the stock solution of the frozen lyophilized excipient in the tray, removing the solvent, and obtaining the lyophilized excipient;

[0091] (f) carry out internal packing, namely obtain cranberry solid instant drink.

Embodiment 2

[0093] (a) Take a rose-shaped mold assembly consisting of two parts that can produce tablets without sharp edges, and pre-cool it to -10°C;

[0094] (b) Stir rose extract: trehalose = 1:10 to form a solution, and vacuum degassing to obtain the stock solution of the freeze-dried excipient;

[0095] (c) Slowly inject the stock solution of the freeze-dried excipient preparation from the filling hole 13 of the mold into the mold for filling by using a filling pump;

[0096] (d) freezing the stock solution of the lyophilized excipient preparation in the mold until the stock solution is completely frozen into a solid;

[0097] (e) Open the mold, take out the freeze-dried excipient stock solution that has been completely frozen, and place it in the tray;

[0098] (f) freeze-drying, removing the solvent to obtain a freeze-dried excipient;

[0099] (g) Carry out inner packing, dissolve with water when using, form the skin care product of ready-to-use type.

Embodiment 3

[0101] (a) Take a mold combination composed of 3 parts, capable of producing tablets without sharp edges, and in the shape of a double-layer tablet, and pre-cool it to -0°C;

[0102] (b) Homogenizing fresh velvet antler: ginseng extract=2:1 to obtain component 1; homogenizing fresh velvet antler: ginseng extract=1:2 to obtain component 2;

[0103] (c) Prepare solutions 1 and 2 by adding water respectively, stir to form solutions, and vacuum degas to obtain lyophilized excipient stock solutions 1 and 2;

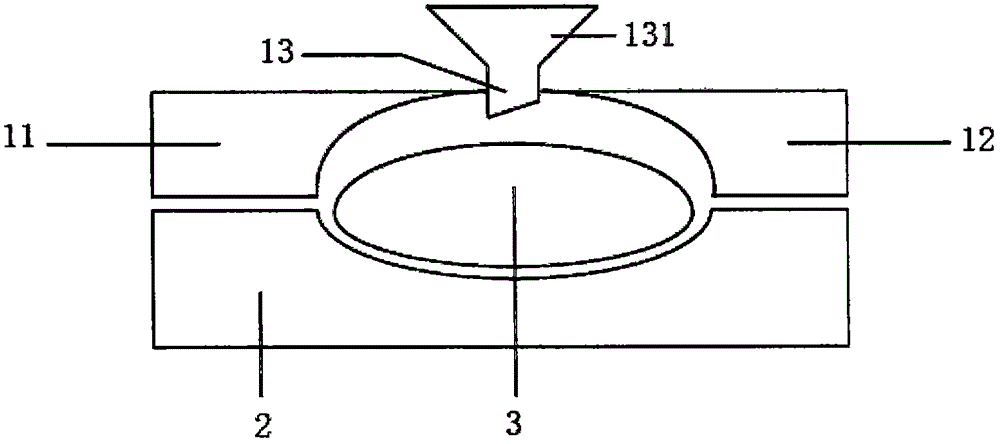

[0104] (d) Use a pipette to slowly inject the stock solution of the freeze-dried excipient preparation from the mold filling connection port 131 into the mold for filling; completely freeze;

[0105] (e) Take out the septum, and use a pipette to slowly inject the stock solution 2 of the freeze-dried excipient preparation from the mold filling connection port 131 into the mold for filling and freezing until the stock solution is completely frozen into a solid;

[0106] (f) Open ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com