Chip automatic separation equipment

An automatic separation and patch technology, applied in labeling machines, packaging, labels, etc., can solve the problems of high production cost, inconvenient operation, complex structure, etc., achieve complete separation of patches, improve work efficiency, and have a high degree of automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

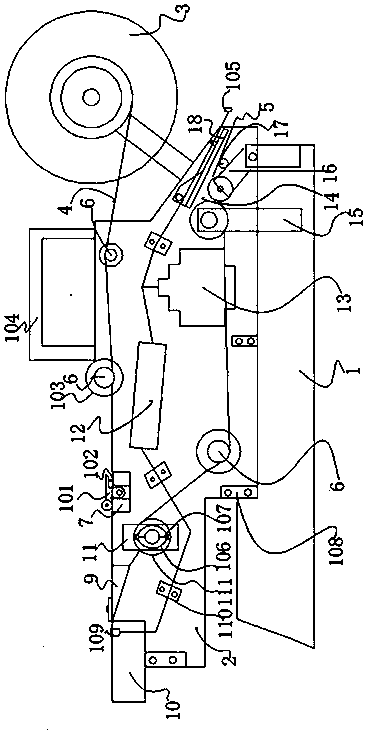

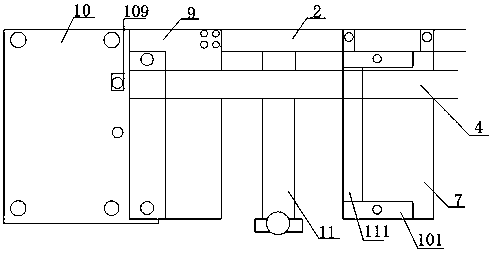

[0021] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0022] Such as figure 1 As shown, a kind of patch automatic separation equipment provided by the present invention includes a base 1, a fixed plate 2 standing on one side of the base 1, a paper reel 3 extending on one side of the fixed plate, and one end above the fixed plate 1 is provided with two Each line position guide roller 6 is separated by a certain distance,

[0023] The other end above the fixing plate 2 is provided with a fixing clip 7, a label stripping plate 8 and a patch placement plate 9 in sequence. A movable line position piece 11 is arranged directly below; the movable line position piece 11 is connected with the transmission guide roller 111 by the L-shaped support (not shown in the figure) through the long screw 107, and the L-shaped support has a polishing hole 106, and the transmission guide roller The raised portion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com