Laser machining device

A laser processing and laser beam technology, which is applied in metal processing, laser welding equipment, metal processing equipment, etc., can solve the problems of rising manufacturing costs, glass coating or insulating coating interface structure and thickness deviation, and suppression of glass coating defects, etc. problems, to achieve the effect of suppressing defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Hereinafter, one embodiment of the present invention will be described in detail with reference to the drawings. In addition, in this specification and drawings, the same code|symbol is attached|subjected to the component which has substantially the same functional structure, and repeated description is abbreviate|omitted.

[0048]

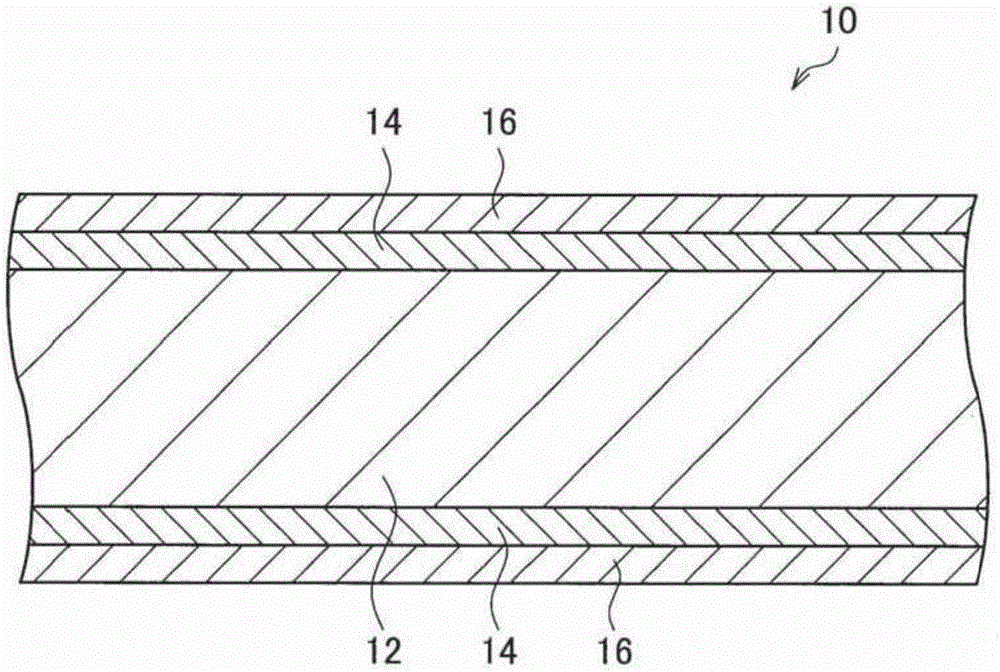

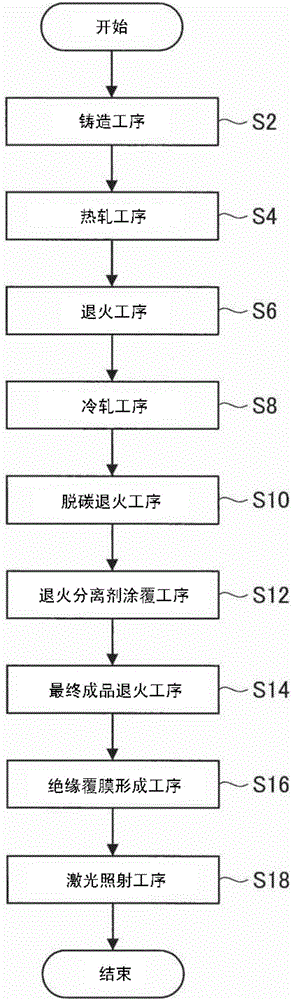

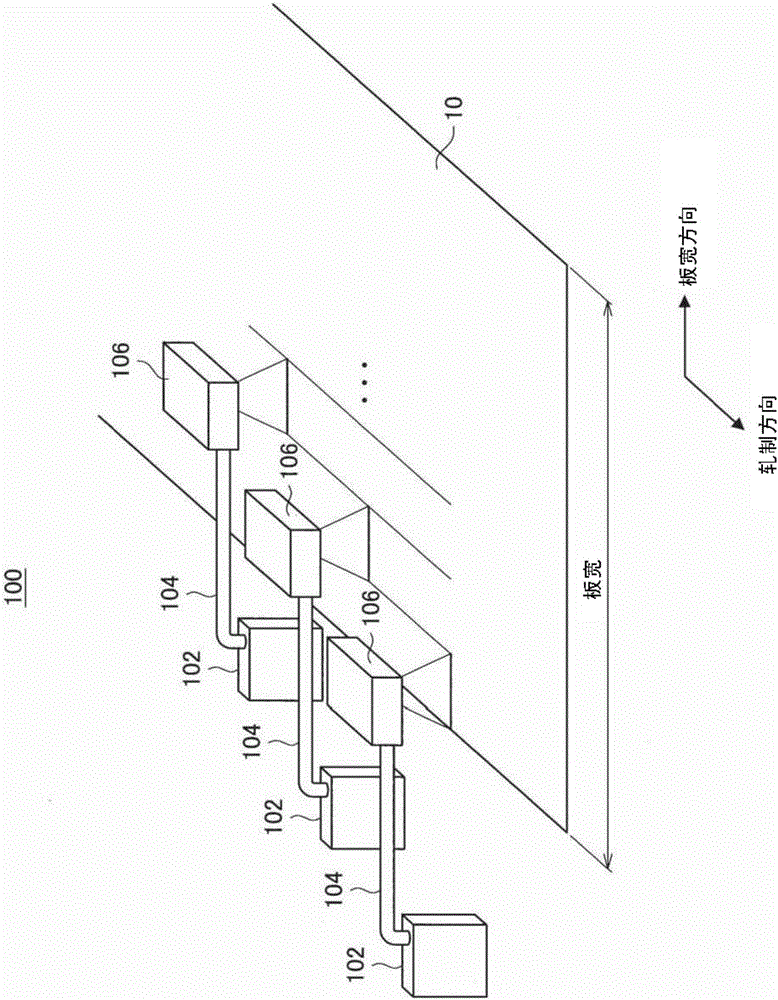

[0049] The grain-oriented electrical steel sheet is an electrical steel sheet in which the axes of easy magnetization (the direction of the body-centered cubic crystal) of the steel sheet are substantially aligned in the rolling direction in the manufacturing process. In the grain-oriented electrical steel sheet as described above, a plurality of magnetic domains whose rolling direction and magnetization direction coincide are arranged in a state separated by magnetic domain walls. Since such grain-oriented electrical steel sheet is easily magnetized in the rolling direction, it is suitable as a core material of a transformer in which th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| degree of polarization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com