Manufacturing method for unidirectional electromagnetic steel sheet

An electromagnetic steel sheet and manufacturing method technology, applied in the direction of the magnetism of inorganic materials, can solve the problems of deviation in the length direction and width direction of the glass film or insulating film, and achieve the effect of suppressing defects and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

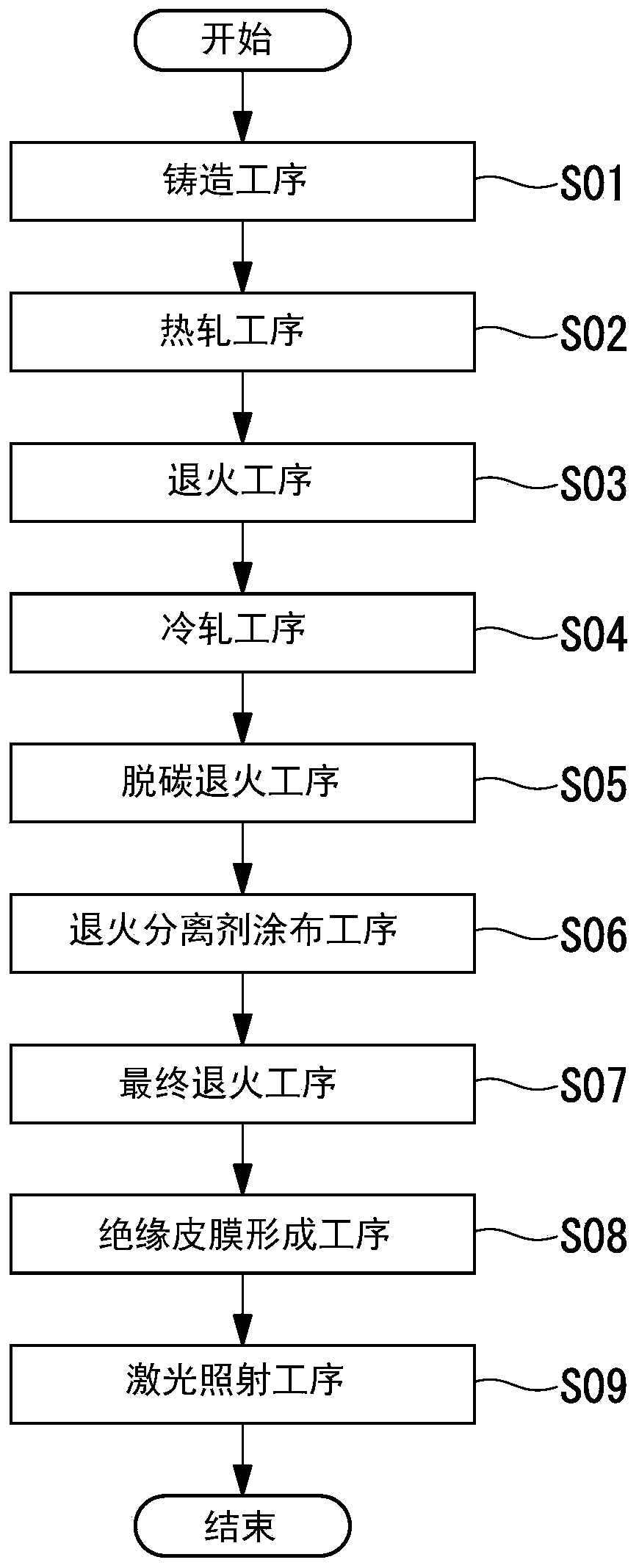

[0057] Next, a confirmation experiment carried out to confirm the effects of the present invention will be described.

[0058] First, prepare a slab having the following composition: 3.0% by mass of Si, 0.05% by mass of C, 0.1% by mass of Mn, 0.02% by mass of acid-soluble Al, 0.01% by mass of N, and 0.01% by mass of S , P is 0.02% by mass, and the remainder contains Fe and unavoidable impurities.

[0059] This slab was hot-rolled at 1280° C. to produce a hot-rolled material with a thickness of 2.3 mm.

[0060] Next, the hot-rolled material was heat-treated under the condition of 1000° C.×1 minute. Pickling treatment was performed after the heat treatment, and cold rolling was performed to produce a cold-rolled material with a thickness of 0.23 mm.

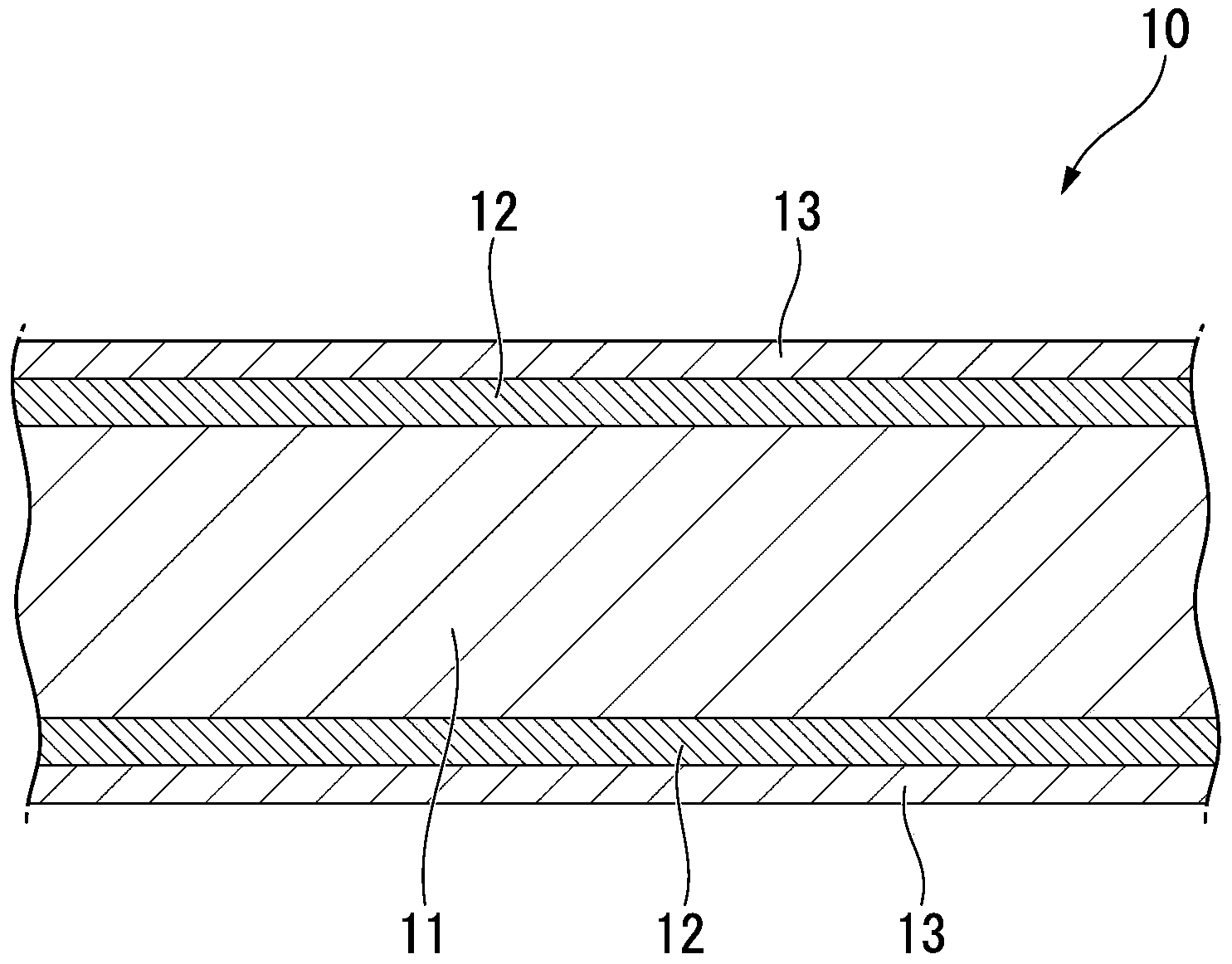

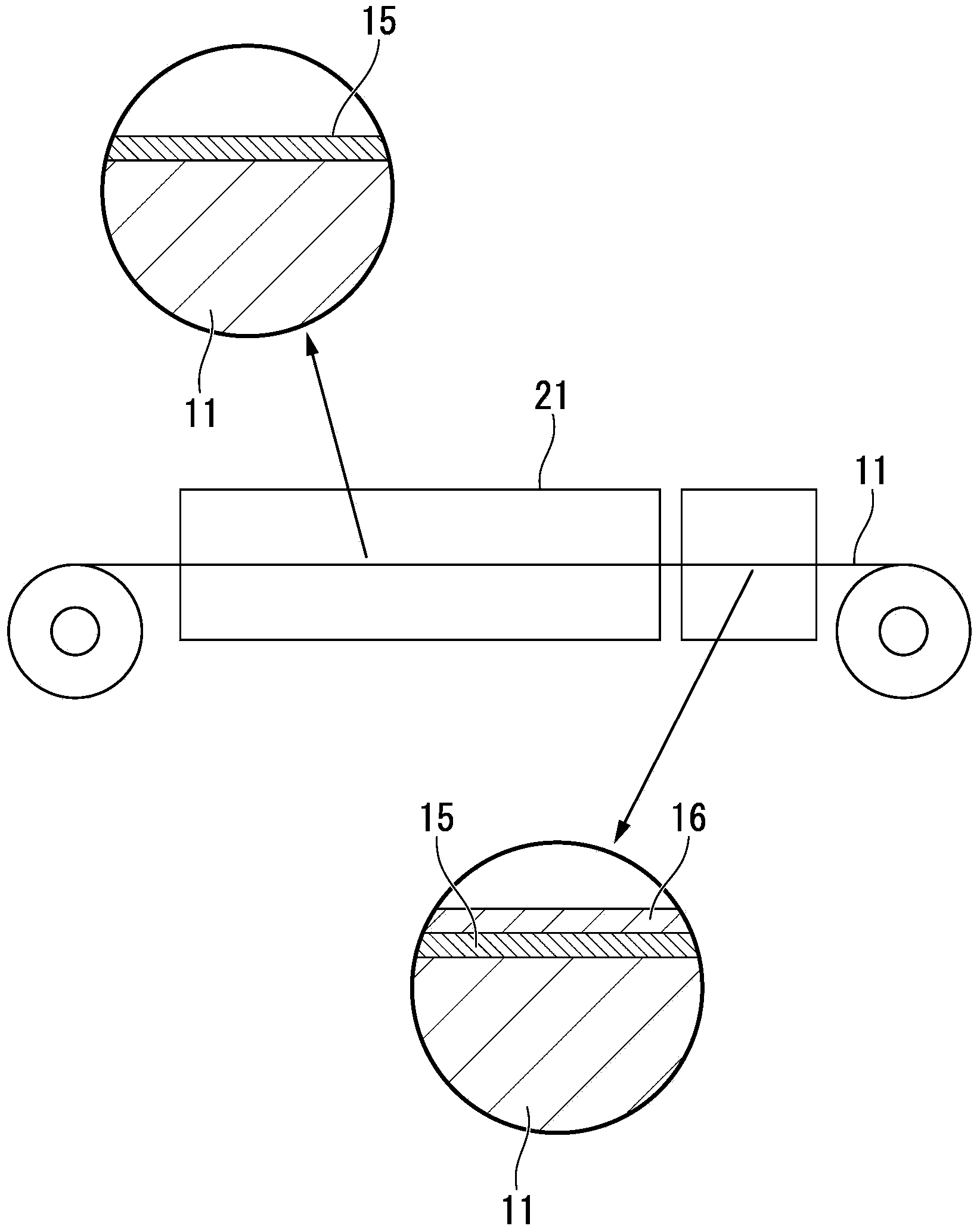

[0061] This cold-rolled material was subjected to decarburization annealing under the conditions of 800° C.×2 minutes. Next, an annealing separation material mainly composed of magnesium oxide was coated on both surfaces of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com