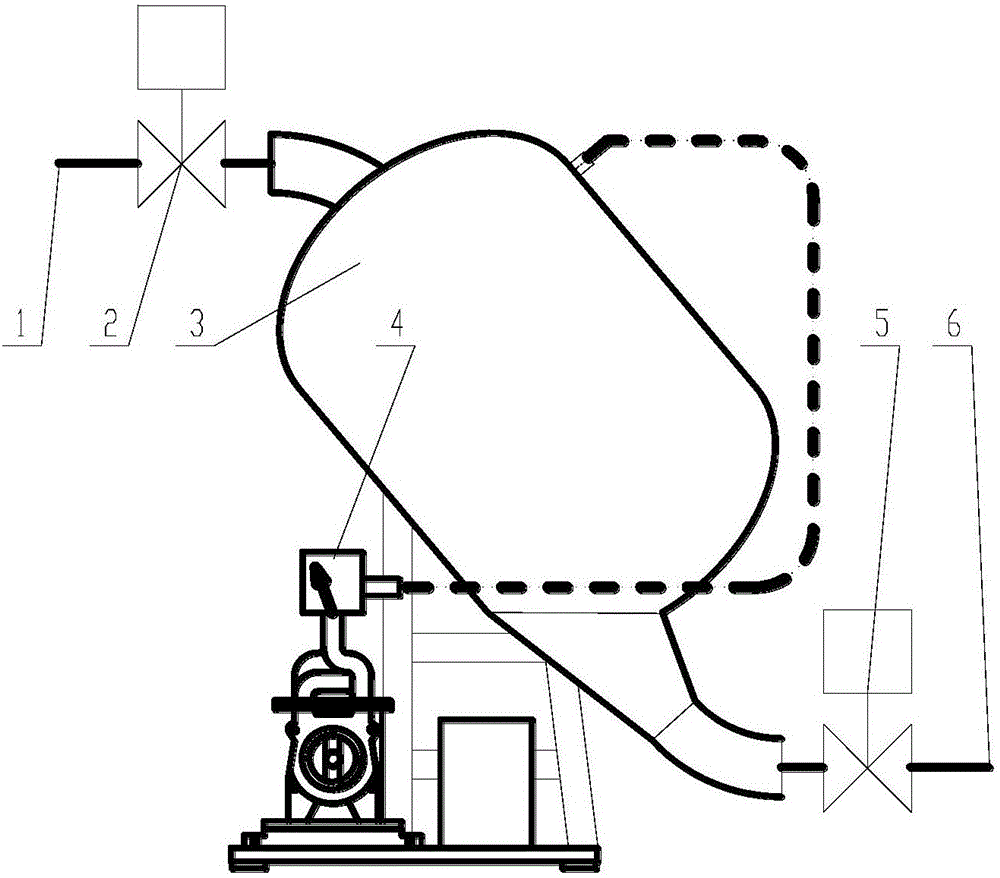

Vacuum fish pump floating on water

A vacuum suction and fish pump technology, applied in fishing, application, animal husbandry, etc., can solve the problems of rising damage rate of live fish, affecting the circulation of live fish, uncoordinated valve control, etc. Effects of fish quality and suction power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

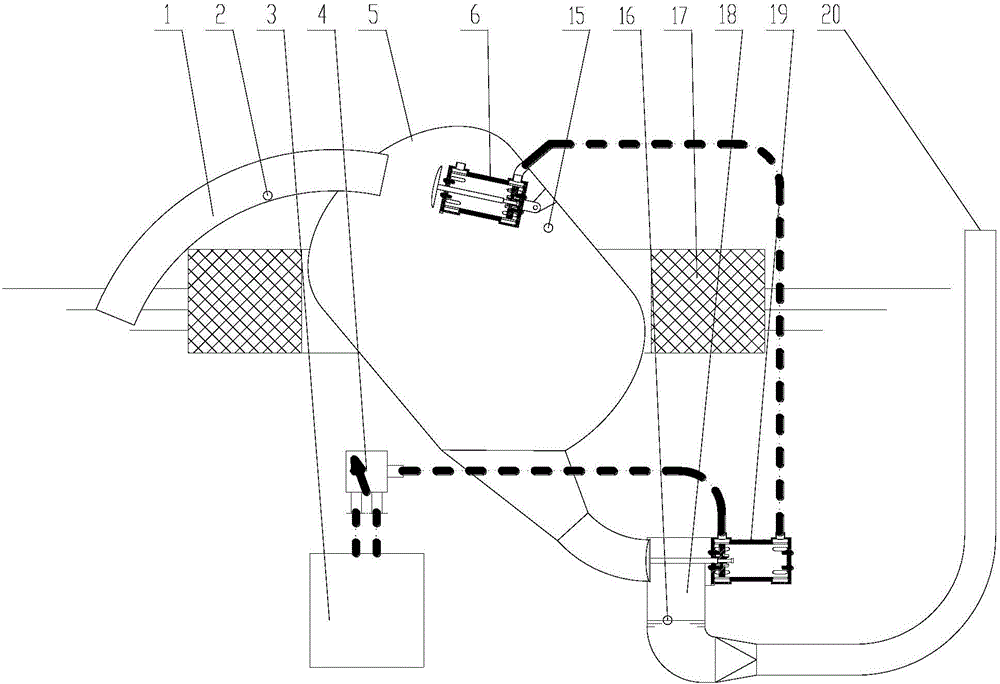

[0040] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

[0041] Such as figure 2 As shown, a vacuum suction fish pump floating on the water surface includes the following components:

[0042] float 17;

[0043] The fish tank 5 arranged on the floating body 17;

[0044] A fish suction pipe 1 communicated with the inlet of the fish tank 5;

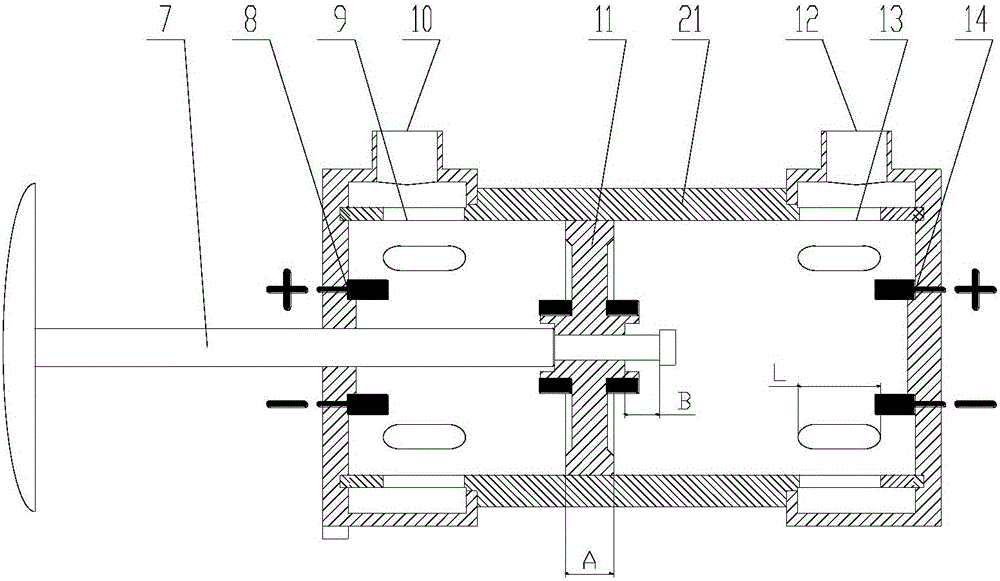

[0045] The first electromagnetic pilot pneumatic valve 6 arranged in the fish tank 5 near the entrance of the fish suction pipe 1 and the second electromagnetic pilot pneumatic valve 19 arranged outside the fish tank 5, the rear air port 12 of the first electromagnetic pilot pneumatic valve 6 It communicates with the rear air port 12 of the second electromagnetic pilot pneumatic valve 19;

[0046] The fish row transition chamber 18 is set on the valve plug connecting rod 7 of the second electromagnetic guiding pneumatic valve 19, and the inlet of the fish row tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com