Automatic Steam Corn Tablet Machine

A fully automatic technology for corn flakes, applied in feed, food science, applications, etc., can solve the problems of increased production costs, waste of corn flakes, and inability to observe the steaming degree of corn, and achieve the effect of improving labor intensity and facilitating operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

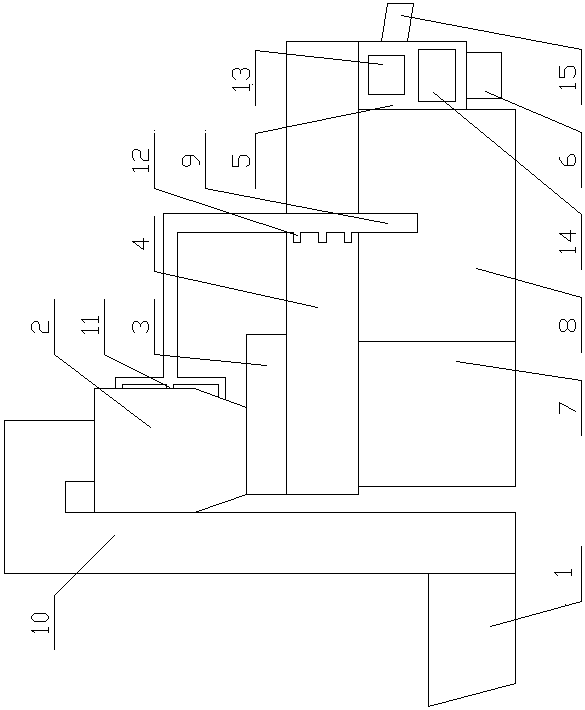

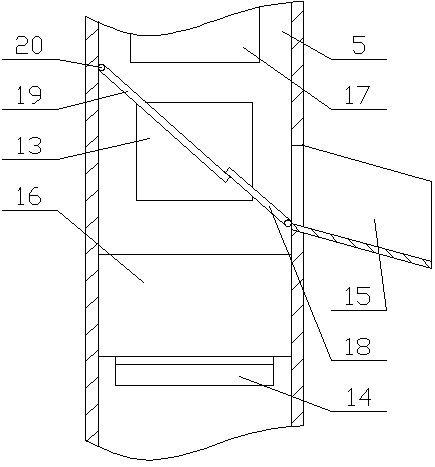

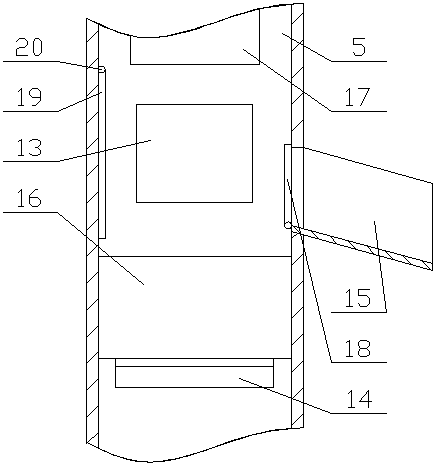

[0044] combine Figure 1~Figure 7 As shown, the present invention comprises feeder 1, and described feeder 1 is communicated with the inlet of digester 2, and the outlet of digester 2 is communicated with the inlet of conditioner 4 through feeder 3, and the outlet of described conditioner 4 is communicated with The inlet of the tablet press 5 is connected, the bottom of the tablet press is provided with a discharge tank 6, the steam of the cooking tank 2 is provided by a steam generator 8, and the steam generator 8 is connected with the control device 7; The steam outlet pipe 9 of the steam generating device 8 communicates with the inside of the cooking tank 2 and the inside of the conditioner 4 respectively.

[0045] The steam outlet pipe 9 communicates with the cooking tank 2 through the steam branch pipe A11, and the steam outlet pipe 9 communicates with the conditioner 4 through the steam branch pipe B12. The steam branch pipe A11 and the steam branch pipe B12 are respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com