A kind of preparation method of synthetic gas methanation to produce natural gas catalyst

A catalyst and natural gas technology, which is applied in the field of preparation of supported molybdenum-based catalysts for synthesis gas methanation to natural gas. Facilitate industrial scale-up, reduce concentration difference, and reduce the effect of metal consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

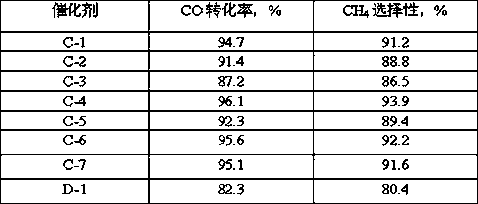

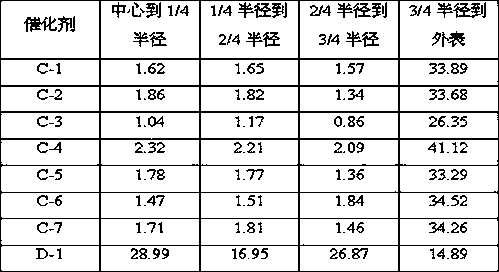

Examples

Embodiment 1

[0028] Weigh 2.97g of nickel nitrate and 2.89g of ferric nitrate and dissolve them in 10mL of deionized water to obtain solution A; use equal volume impregnation method to load on 12.9g of alumina carrier (pore volume is 0.73mL / g, specific surface area is 253m 2 / g, strip shape, equivalent diameter 1.5mm), impregnated at room temperature for 2h, aged for 4h, dried at 80°C for 12h, and calcined at 700°C for 4h to prepare catalyst precursor B. The supported Ni was 3% by weight of the final catalyst %, the supported Fe is 2% of the final catalyst based on the weight of the element; the catalyst precursor B is activated in a mixed atmosphere containing hydrogen, the volume content of hydrogen in the mixed gas is 80%, and the reducing conditions are 450 ° C, 0.2 MPa (absolute pressure), the reduction time was 4h; 1.86g of cerium nitrate was dissolved in 15mL of deionized water to obtain solution C, and it was mixed uniformly with 40% furfural aqueous solution with a mass fraction of...

Embodiment 2

[0030] Weigh 2.97g of nickel nitrate and 2.89g of ferric nitrate and dissolve them in 10mL of deionized water to obtain solution A; use equal volume impregnation method to load on 12.9g of silica carrier (pore volume is 0.97mL / g, specific surface area is 372m 2 / g, spherical shape, equivalent diameter 0.5mm), impregnated at room temperature for 2h, aged for 4h, dried at 80°C for 12h, and calcined at 700°C for 4h to prepare catalyst precursor B. The supported Ni was 3% of the final catalyst based on the weight of the element , the supported Fe is 2% of the final catalyst based on the weight of the element; the catalyst precursor B is activated in a mixed atmosphere containing hydrogen, the volume content of hydrogen in the mixed gas is 80%, and the reducing conditions are 450 ° C, 0.2 MPa (absolute pressure ), the reduction time was 4h; 1.86g of cerium nitrate was dissolved in 15mL of deionized water to obtain solution C, and it was mixed uniformly with 40% furfural aqueous solu...

Embodiment 3

[0032] Weigh 0.99g of nickel nitrate and 1.44g of ferric nitrate and dissolve them in 14mL of deionized water to obtain solution A; use equal volume impregnation method to load on 15g of alumina carrier (pore volume is 0.73mL / g, specific surface area is 253m 2 / g, strip shape, equivalent diameter 1.5mm), impregnated at room temperature for 2h, aged for 4h, dried at 80°C for 12h, and calcined at 700°C for 4h to prepare the catalyst precursor B. %, the supported Fe is 1% of the final catalyst based on the weight of the element; the catalyst precursor B is activated in a mixed atmosphere containing hydrogen, the volume content of hydrogen in the mixed gas is 80%, and the reducing conditions are 450 ° C, 0.2 MPa (absolute pressure), the reduction time was 4h; 0.62g of cerium nitrate was dissolved in 15mL of deionized water to obtain solution C, and it was mixed uniformly with 40% furfural aqueous solution with a mass fraction of 4 times its mass, and then mixed with the reduced and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com