Automobile plastic lateral baffle

A side baffle and plastic technology, which is applied in the field of auto parts, can solve the problems of easily broken connecting threads and low assembly efficiency, and achieve high assembly efficiency, improve assembly efficiency, and ensure connection fixity and durability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

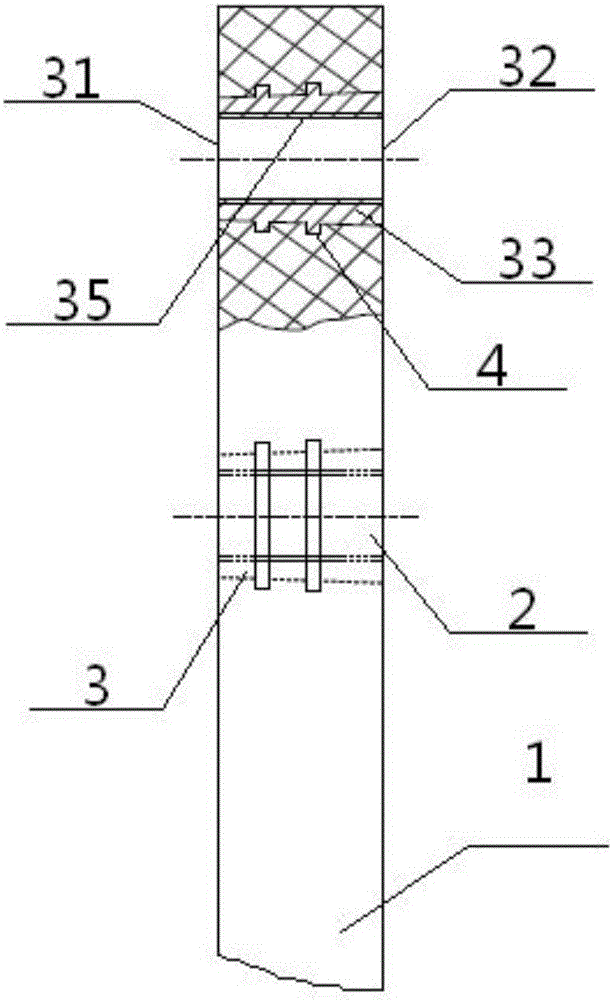

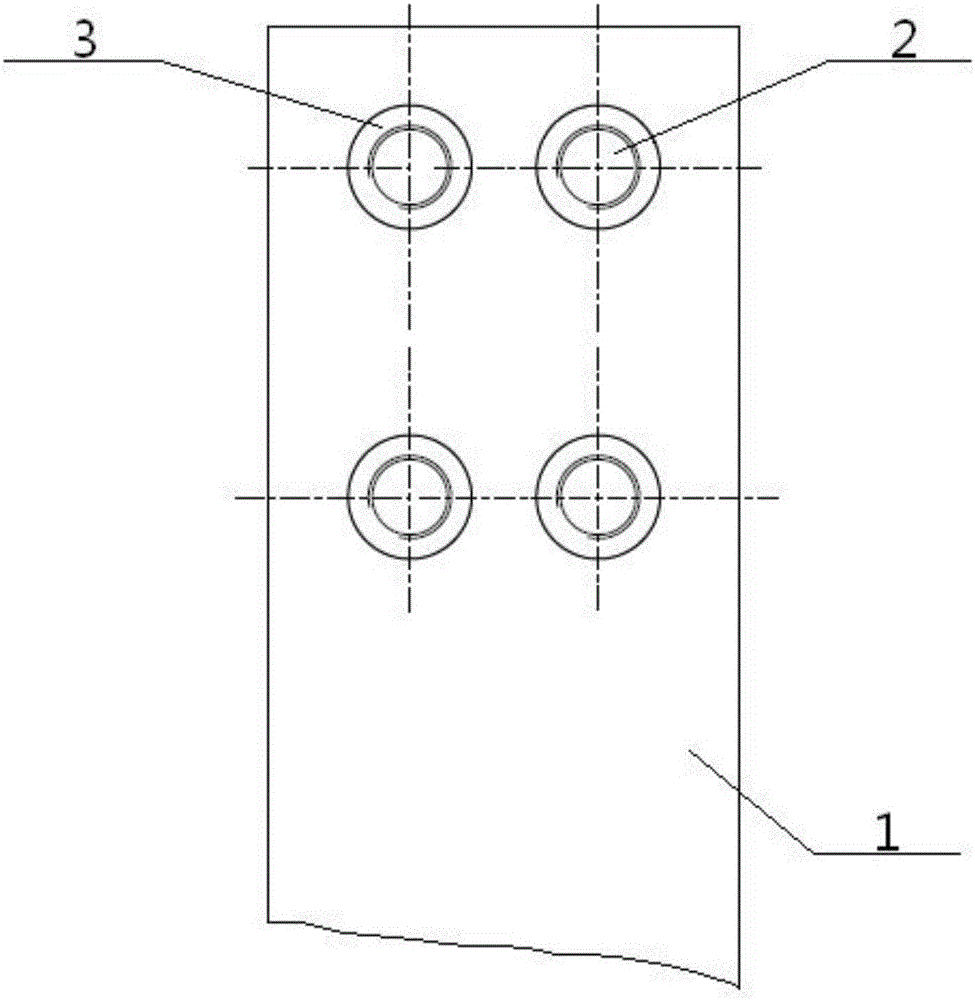

[0055] see Figure 1 to Figure 6 , a plastic side panel for automobiles, comprising a plastic body 1 and a plurality of metal threaded inserts 3 inlaid thereon, the metal threaded inserts 3 are hollow structures, the outer walls of the metal threaded inserts 3 are in contact with the interior of the plastic body 1 For fixed connection, threads are provided on the inner cavity wall 35 of the metal threaded insert 3 to form the threaded hole 2 .

Embodiment 2

[0057] Basic content is the same as embodiment 1, the difference is:

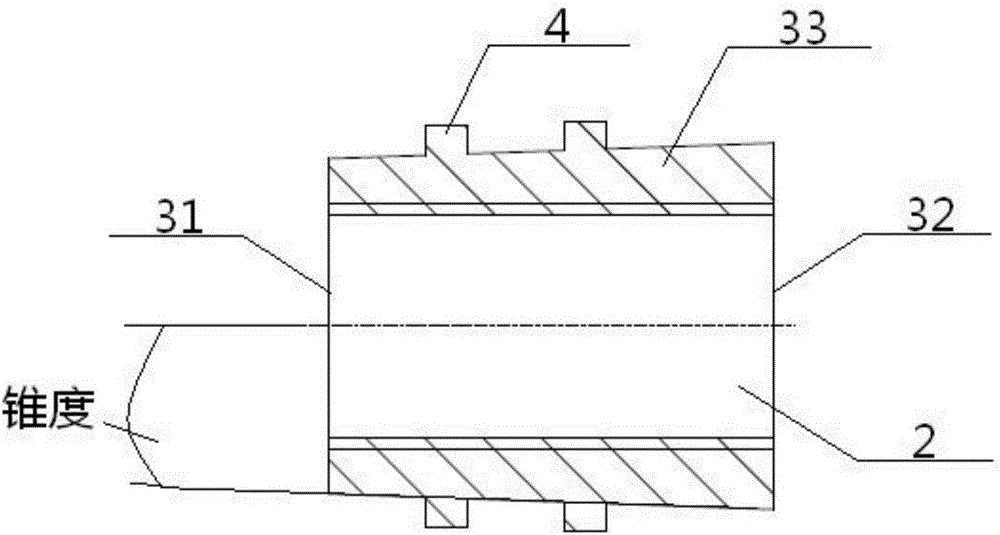

[0058] The metal threaded insert 3 is a cone-shaped conical structure, including a narrow table 31, a wide table 32 and a truncated cone 33 between them. The narrow table 31 is flush with the inner surface of the plastic body 1, and the width The table surface 32 is flush with the outer surface of the plastic body 1 , and the frustum portion 33 is a hollow structure, and the inner wall thereof is provided with threads to form the threaded hole 2 . The diameter of the narrow mesa 31 is smaller than that of the wide mesa 32, and the taper of the truncated portion 33 is 2-5 degrees.

Embodiment 3

[0060] Basic content is the same as embodiment 2, the difference is:

[0061] At least two annular protrusions 4 are provided on the outer wall of the frustum portion 33 to be fixedly connected with the interior of the plastic body 1 . The structure of the annular protrusion 4 is one of the following two types:

[0062] The first type: the shape of the annular protrusion 4 is an annular pie shape, the bottom of the annular protrusion 4 is connected with the outer wall of the frustum part 33, and the top and side of the annular protrusion 4 are connected with the plastic The interior of the body 1 is fixedly connected, and the surface where the annular protrusion 4 is located is perpendicular to the central axis of the frustum portion 33;

[0063] The second type: the annular protrusion 4 is a hollow conical sleeve 5 , the conical sleeve 5 is arranged coaxially with the truncated portion 33 , and a plurality of slurry holes 51 are opened on the conical sleeve 5 . The ratio of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com