A heat pump air conditioner unit, its control method and electric passenger car

A heat pump air conditioner and control method technology, which is applied to vehicle components, air handling equipment, heating/cooling equipment, etc., can solve problems such as indoor temperature reduction, and achieve the effect of improving system reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

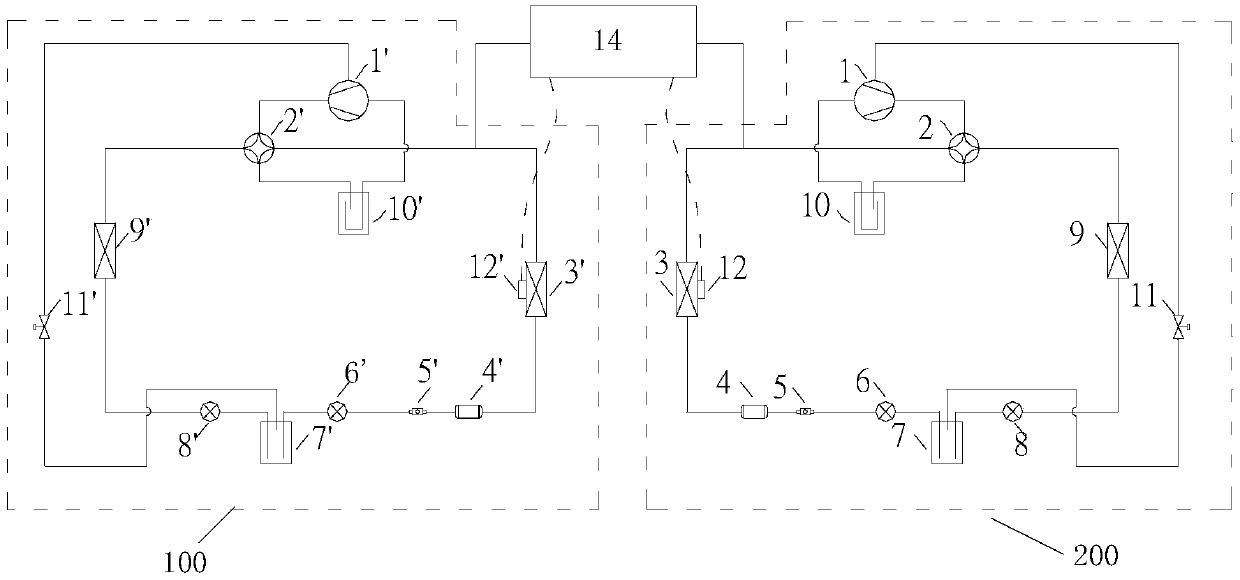

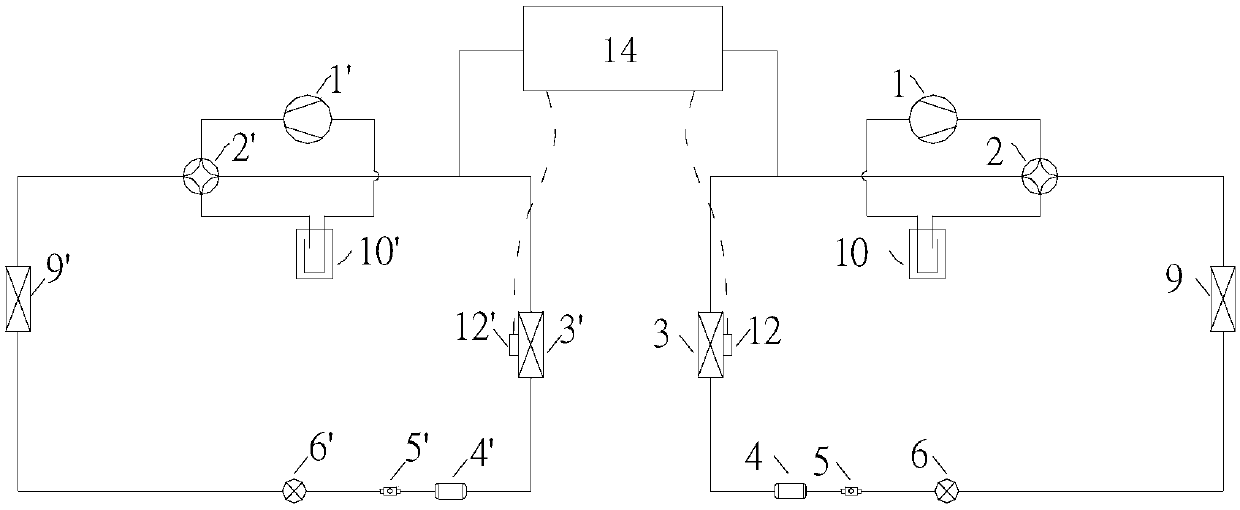

[0093] Among them, key parameters such as the operating parameters of the system, the opening and closing of air supply and ventilation solenoid valves, the adjustment of the throttle valve, the reading of the temperature sensor parameters, and whether defrosting or not are all controlled by the centralized control unit. The present invention proposes a pure electric passenger car air-conditioning system that can defrost in partitions. By setting up two sets of independent heat pump air-conditioning systems and using a centralized control unit, it is used for cooling and heating in the car, and when it is in a low-temperature environment, Sequentially defrost the left and right systems to ensure that at least one subsystem in the whole system is in normal heating mode. At this time, the hot air on one side can be sent to the other side through the connected air duct to meet the heat requirements in the car. comfort needs.

[0094] Option One:

[0095] figure 1 Shown is a sch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com