A sample collection device for automatically accessing and storing sample barrels

An automatic access and sample collection technology, applied in storage devices, transportation and packaging, conveyors, etc., can solve problems such as affecting sample test results and production and operation, low production efficiency of collection devices, and affecting enterprise production and operation, etc., to avoid problems. Long exchange, shorter residence time, guaranteed authenticity and representative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

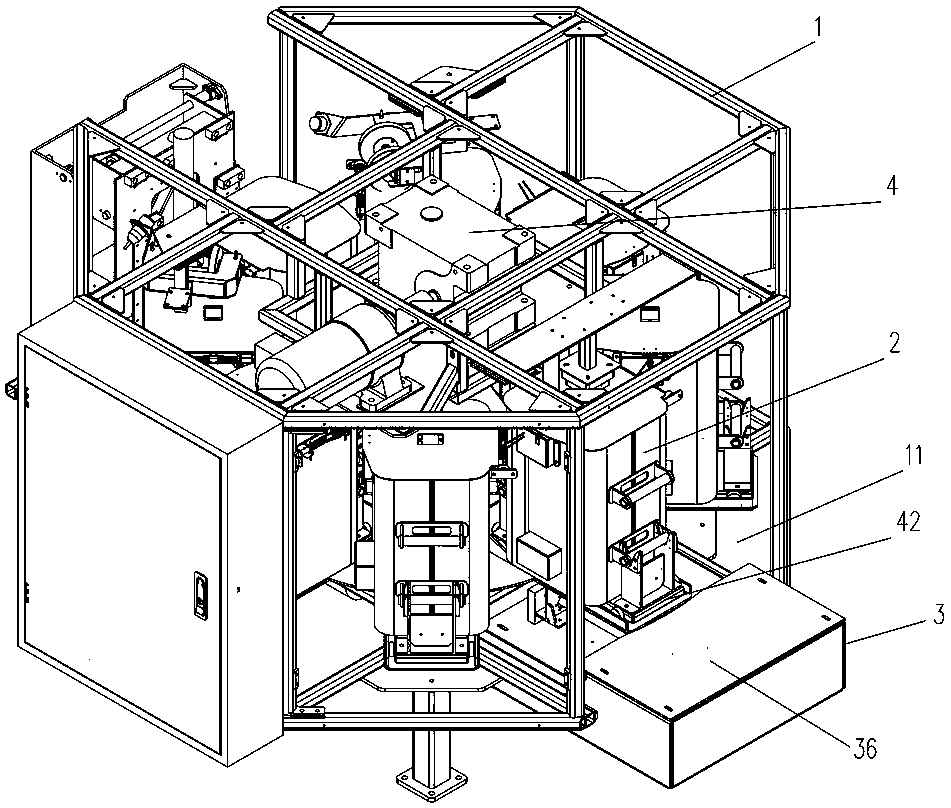

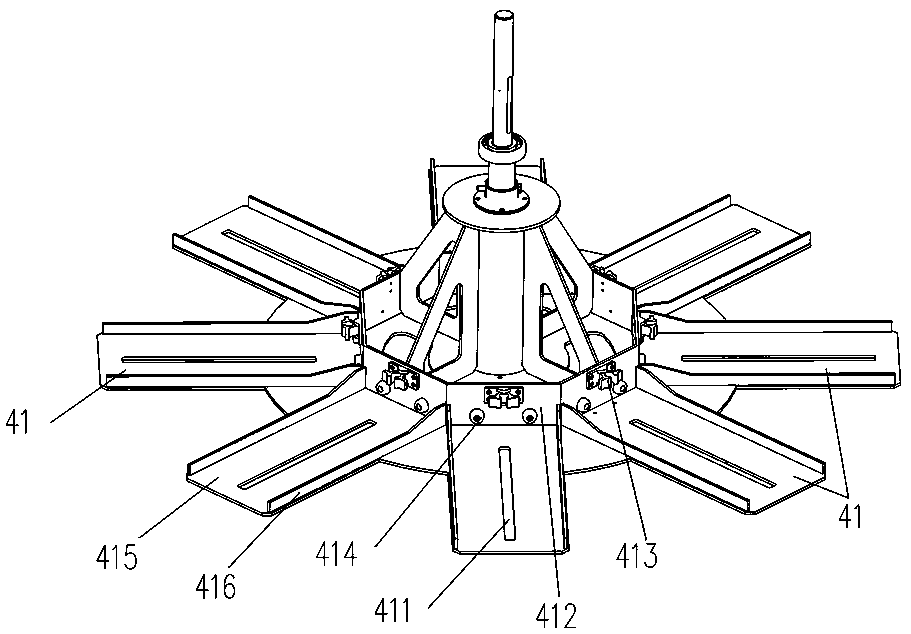

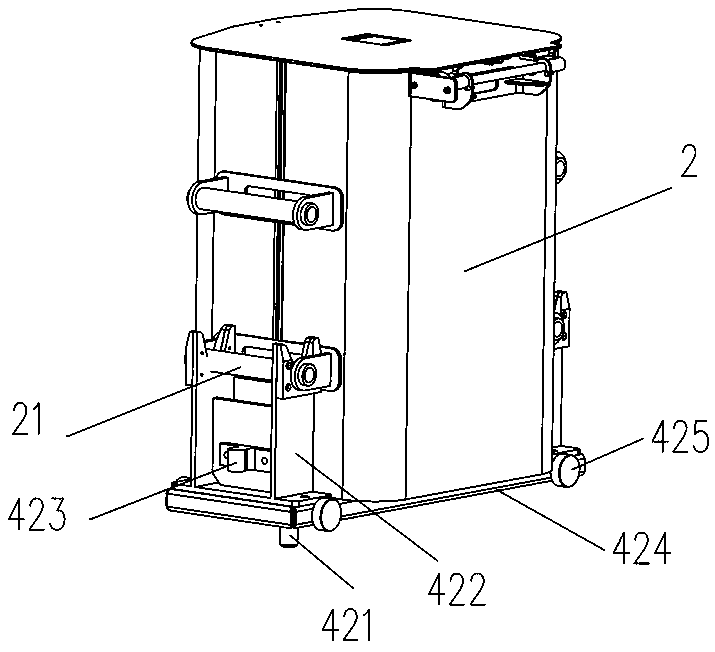

[0037] Such as Figure 1 to Figure 4 As shown, the present invention provides a sample collection device for automatically accessing and storing sample buckets. The barrel 2 and the side of the frame 1 are provided with an inlet 11 for the sample barrel 2 to enter and exit the collection cavity. The turntable mechanism 4 includes a plurality of turntable bases 41 arranged in turn in a disc, and each turntable base 41 is provided with a The sliding bearing seat 42 carrying the sample storage barrel 2, each sliding bearing seat 42 can slide back and forth on the turntable base 41, and the entrance 11 is also provided with a sliding drive mechanism 3 matched with the sliding bearing seat 42, when the turntable base 41 When rotating to the entrance 11, the sliding drive mechanism 3 drives the sliding bearing seat 42 to slide out of the entra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com