A process for producing liquid fuel by fractional conversion of sludge

A technology of liquid fuel and process method, which is applied in the direction of chemical instruments and methods, sludge treatment, immiscible solvent sludge treatment, etc., can solve the problems of affecting economic benefits and yield reduction, and achieve zero discharge and pollution The effect of mud resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

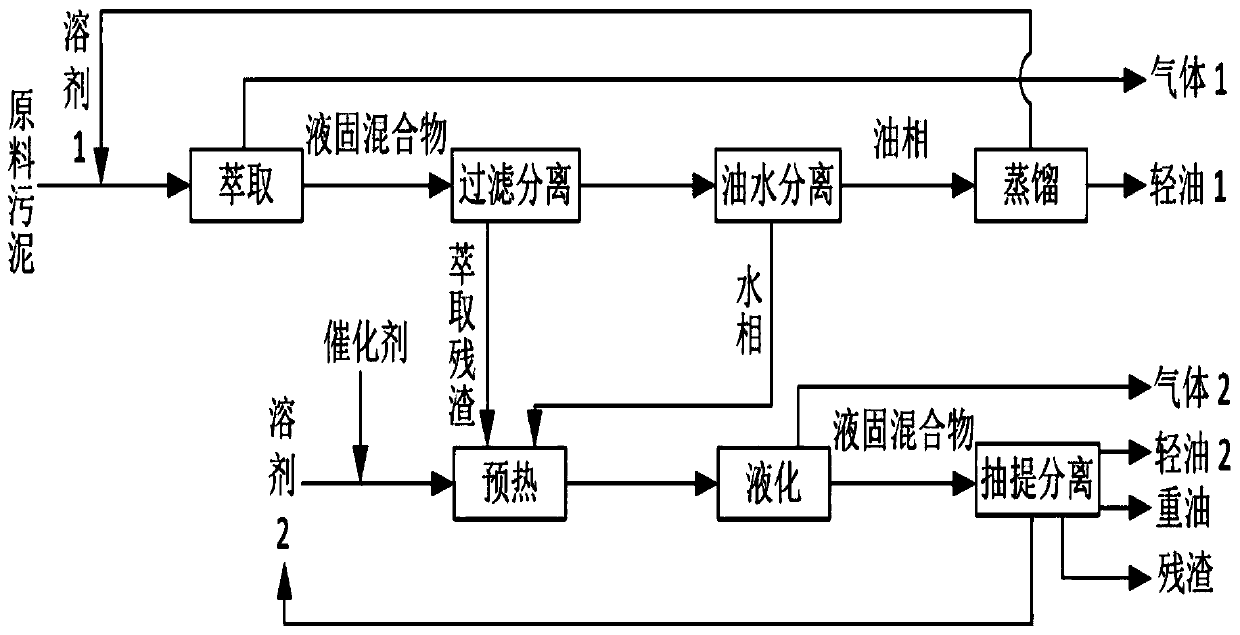

Method used

Image

Examples

Embodiment 1

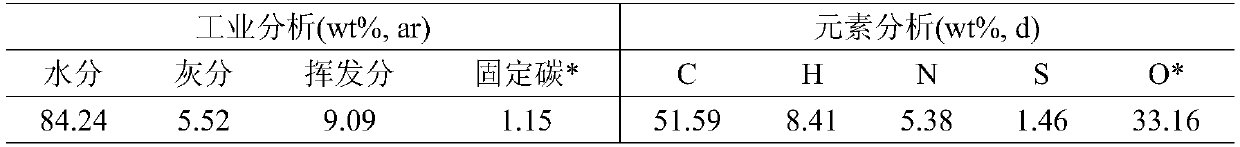

[0037] Embodiment 1: Accurately weigh 100g of raw material sludge and 300g of n-hexane, mix uniformly to form a slurry, add it to a tank reactor, and after nitrogen replacement, the temperature of the reactor is raised to 300°C (reaction pressure 11.3MPa), Extract under these conditions for 30 minutes; after the extraction is completed, gas 1 and the extracted liquid-solid mixture are obtained, and the liquid-solid mixture is filtered to obtain the oil-water liquid mixture and the extraction residue; the oil-water mixture is phase-separated to obtain the oil phase and the water phase, and the oil The distilled phase was distilled to obtain light oil 1 and n-hexane; the aqueous phase and the extraction residue were transferred to a tank reactor, and 1gNa 2 CO 3 and 100g tetrahydrofuran, filled with 4MPa of CO gas, then the reactor was raised to 300°C (reaction pressure 15.1MPa), and the liquefaction reaction was carried out for 30min; after the liquefaction reaction was complet...

Embodiment 2~6

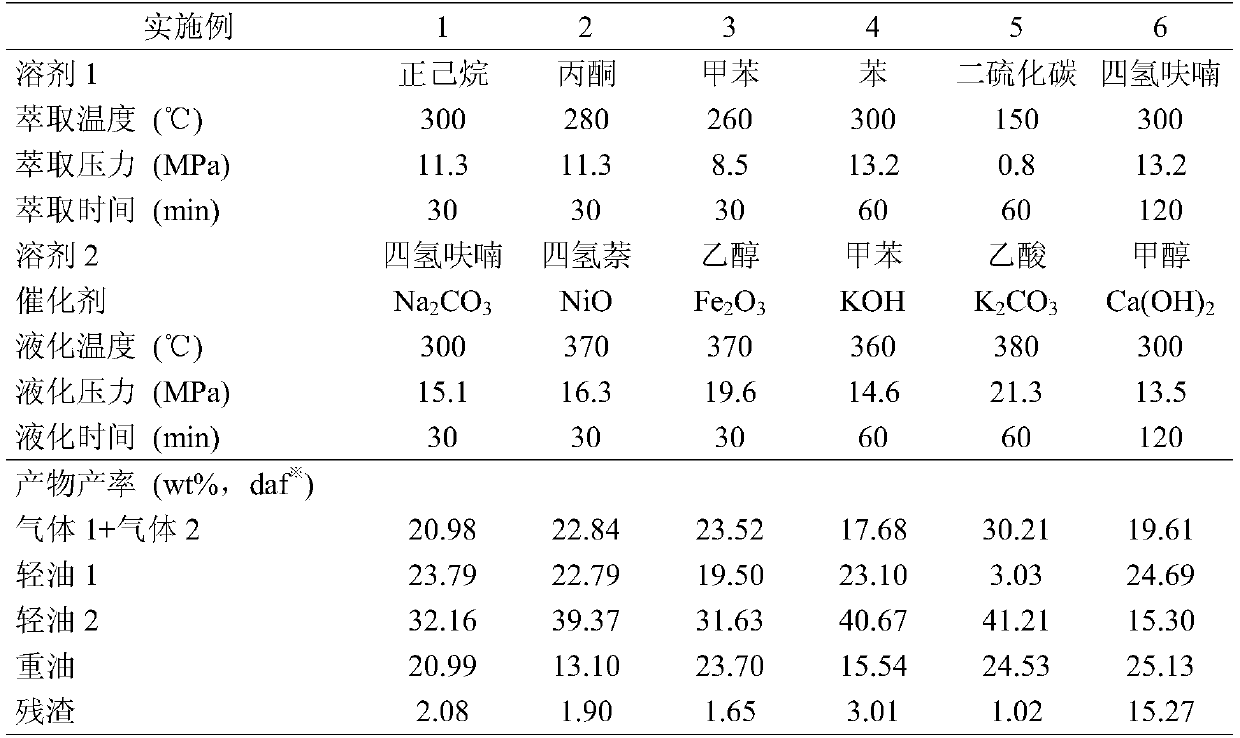

[0042] Embodiments 2-6: Similar operations were performed as in Embodiment 1, except that the reaction conditions, solvent 1, solvent 2 and catalyst were also different, and other steps were the same.

[0043] The reaction conditions and results of Examples 1-6 are shown in Table 2.

[0044] The reaction conditions and the result of table 2 embodiment 1~6

[0045]

[0046] ※ The yields of the above products are all based on the quality of anhydrous and ash-free sludge

[0047] It can be seen from the examples that the present invention recycles most of the organic matter in the sludge, obtains high value-added liquid fuel, and realizes the sludge harmlessness, reduction, energy utilization and resource utilization.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com