A kind of composite improver for gleization soil and its application

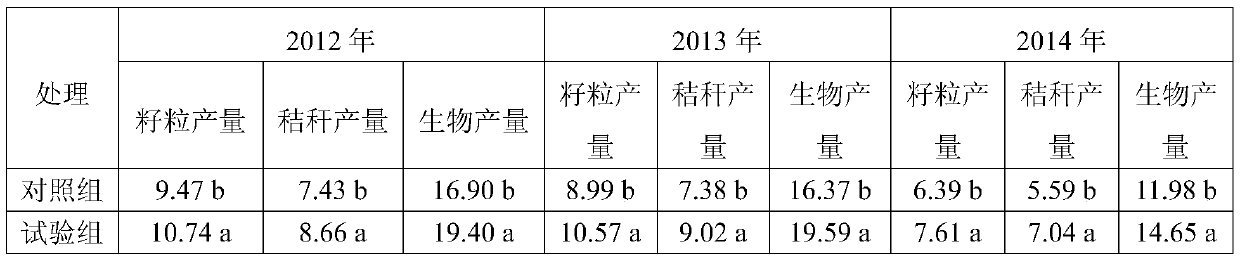

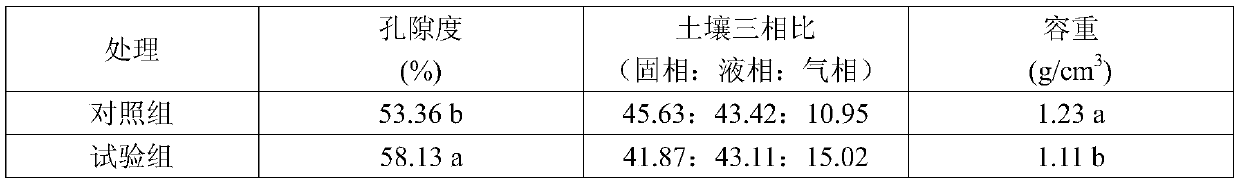

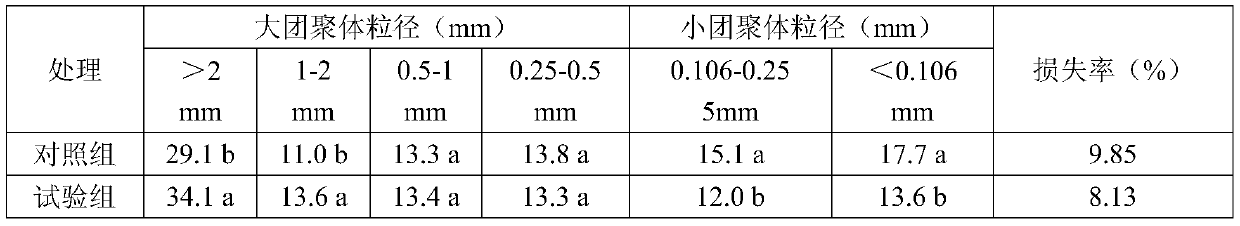

A technology of improver and gleization, which is applied in the field of compound improver for gleization soil, can solve the problems of poor improvement effects such as soil aggregate structure, soil permeability, etc., reduce the content of soil reducing substances, improve soil The content of available nutrients and the effect of activating soil nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] A compound improver for gleization soil, comprising the following components by weight:

[0056] 8 parts of quicklime; 23 parts of fly ash; 57 parts of fermented and decomposed cow dung; 12 parts of fermented and decomposed rapeseed dry cake. The four components are mixed evenly to make a compound improver.

[0057] The preparation method of the fermented and decomposed cow dung is as follows:

[0058] Mix fresh cow dung, grain bran and urea evenly in a weight ratio of 673:320:7, then add 0.5% of the total weight of the mixture as an organic material decomposing agent, and then adjust the moisture content to 55%, stack and ferment, every 2- Turn over once every 3 days, decompose after 15-20 days, and dry it for later use. The nutrient content of cow dung (fresh base) is N 0.40%, P 2 o 5 0.10%, K 2 O 0.23%.

[0059] The preparation method of the fermented and decomposed rapeseed dry cake is as follows:

[0060] Mix rapeseed dry cake and rice bran evenly at a weig...

Embodiment 2

[0063] A compound improver for gleization soil, comprising the following components by weight:

[0064] 5 parts of quicklime; 30 parts of fly ash; 50 parts of fermented and decomposed cow dung; 15 parts of fermented and decomposed rapeseed dry cake. The four components are mixed evenly to make a compound improver.

[0065] The preparation method of the fermented and decomposed cow dung is as follows:

[0066] Mix fresh cow dung, grain bran and urea evenly in a weight ratio of 645:350:5, then add 0.5% of the total weight of the mixture as an organic material decomposing agent, and then adjust the moisture content to 55%, stack and ferment, every 2- Turn over once every 3 days, decompose after 15-20 days, and dry it for later use. The nutrient content of cow dung (fresh base) is N 0.44%, P 2 o 5 0.13%, K 2 O 0.28%.

[0067] The preparation method of the fermented and decomposed rapeseed dry cake is as follows:

[0068] Mix rapeseed dry cake and grain bran evenly at a wei...

Embodiment 3

[0085] A compound improver for gleization soil, comprising the following components by weight:

[0086] 10 parts of quicklime; 20 parts of fly ash; 60 parts of fermented and decomposed cow dung; 10 parts of fermented and decomposed rapeseed dry cake. The four components are mixed evenly to make a compound improver.

[0087] The preparation method of the fermented and decomposed cow dung is as follows:

[0088] Mix fresh cow dung, grain bran and urea evenly in a weight ratio of 690:300:10, then add 0.5% of the total weight of the mixture as an organic material decomposing agent, and then adjust the moisture content to 55%, stack and ferment, every 2- Turn over once every 3 days, decompose after 15-20 days, and dry it for later use. The nutrient content of cow dung (fresh base) is N 0.35%, P 2 o 5 0.09%, K 2 O 0.19%.

[0089] The preparation method of the fermented and decomposed rapeseed dry cake is as follows:

[0090] Mix rapeseed dry cake and rice bran evenly at a we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com