Solid solution system facilitating rapid heating and shock cooling

A rapid heating and quenching technology, which is applied in furnaces, heat treatment equipment, heat treatment furnaces, etc., can solve the problems that the performance of heat exchange tubes is greatly affected, and it is not suitable for duplex stainless steel 2205, etc., to achieve the effect of rapid cooling, simple structure, axial good flow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

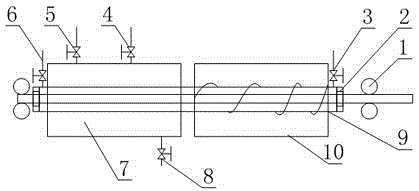

[0021] Such as figure 1 As shown, it is used for solution treatment of duplex stainless steel pipes after welding, including two sets of driving wheel sets 1 located on the same straight line, anti-oxidation pipe 9 between the two sets of driving wheel sets 1 and sleeved on the anti-oxidation pipe 9 on the cooling chamber 7 and the heating chamber 10, the anti-oxidation pipe 9 is a tubular structure with a sealing ring 2 at both ends, the driving wheel set 1 includes two driving wheels, and the two driving wheels There is a gap for accommodating stainless steel pipes between them, the gap is located on the axis of the anti-oxidation pipe 9, and the anti-oxidation pipe 9 is also provided with an air outlet 3 and an air outlet, and the cooling chamber 7 and the heating chamber 10 are located at the air outlet 3 between the air outlet;

[0022] Described cooling chamber 7 is the water storage container that is provided with water inlet 8 and water outlet 5 on it, and described w...

Embodiment 2

[0026] The present embodiment is further limited on the basis of embodiment 1, as figure 1 As shown, in order to control the transmission speed of the duplex stainless steel pipe in the anti-oxidation pipe 9 and control the movement state of the duplex stainless steel pipe, the two sets of driving wheels 1 are located on the same horizontal plane.

[0027] In order to facilitate the control of the process parameters of the heating chamber 10 and the cooling chamber 7 , temperature sensors are installed in the heating chamber 10 and the cooling chamber 7 .

[0028] In order to facilitate the safety of the cooling chamber 7, a safety valve 4 is also provided on the cooling chamber 7.

[0029] In order to enable the protective gas to be used as a heat carrier to facilitate the rapid cooling of the duplex stainless steel pipe in the cooling chamber 7, the gas outlet 3 is located at the end of the anti-oxidation pipe 9 where the heating chamber 10 is disposed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com