Gradient utilization device and method for residual pressure and residual heat in still kettles for aerated concrete blocks

An air-entrained concrete and autoclave technology, which is applied in the field of building material processing, can solve the problems of waste of resources and the inability to reuse high-pressure steam well, and achieve the effect of reducing corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following is attached Figure 1-5 The application is described in further detail.

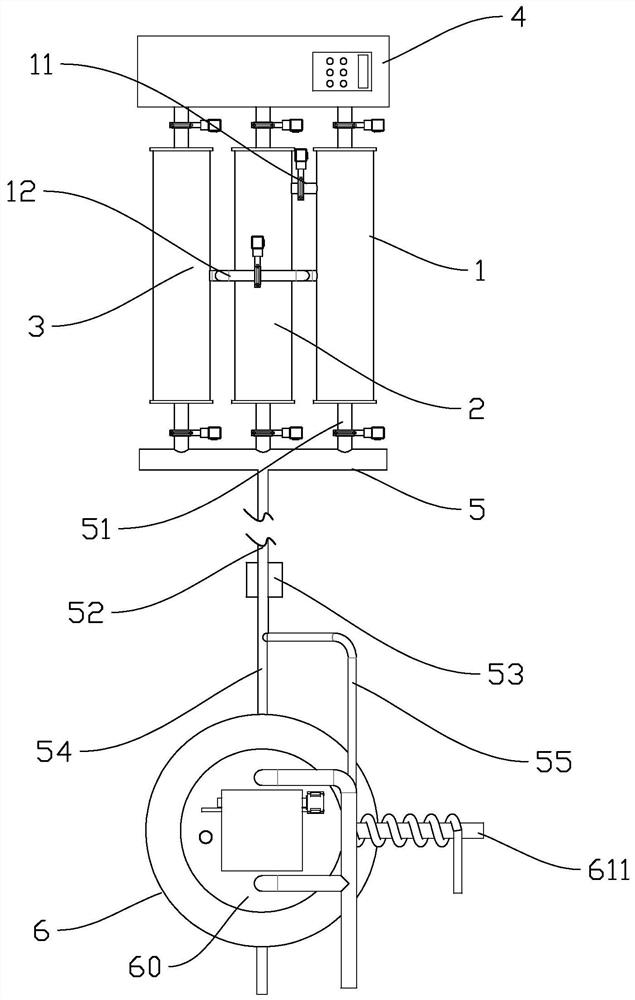

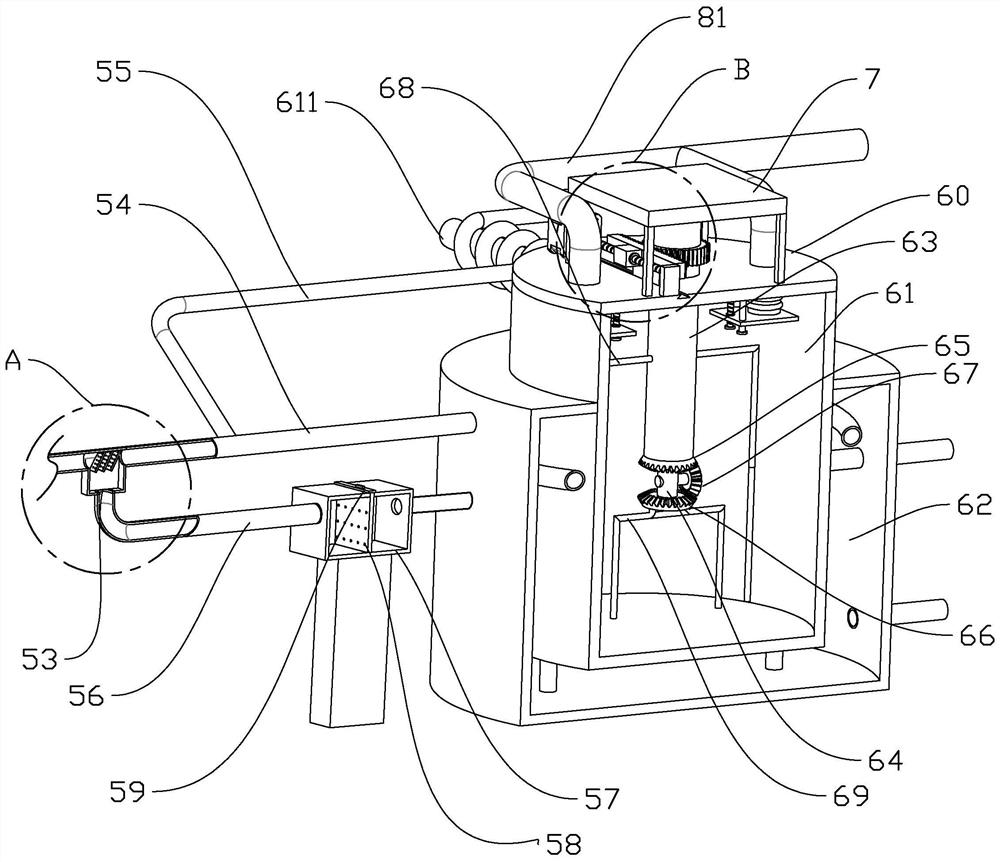

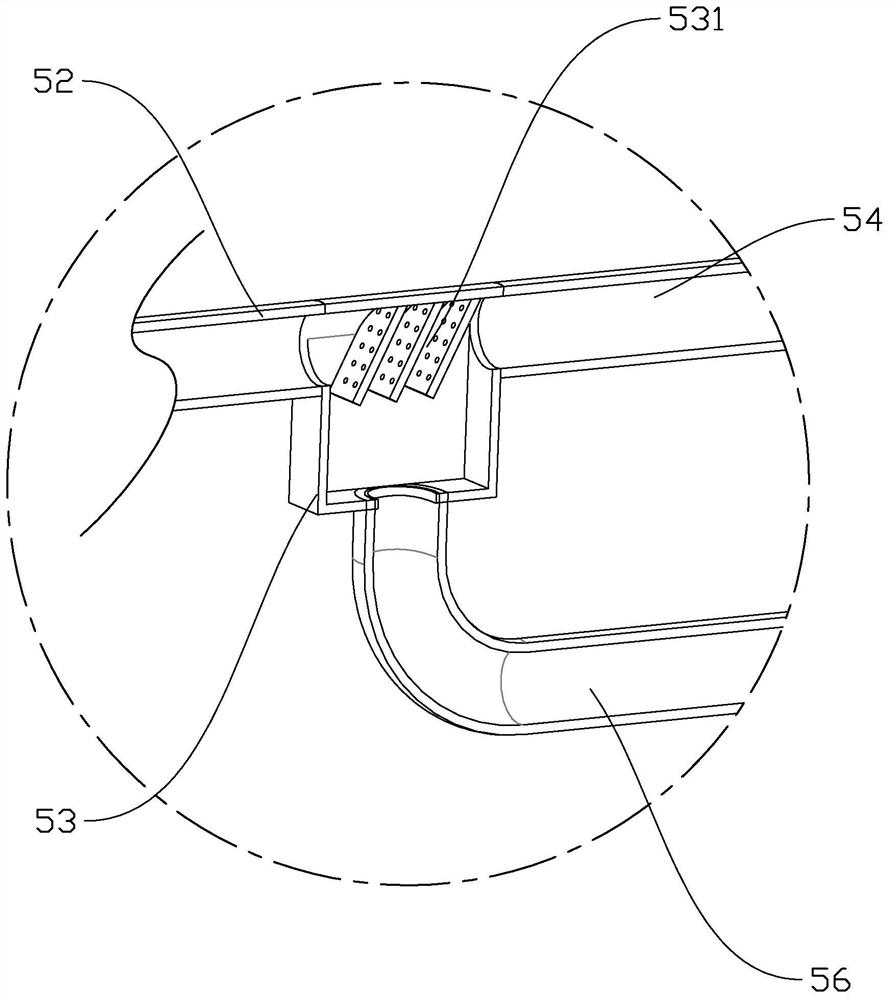

[0039] The embodiment of the present application discloses a cascaded utilization device for residual pressure and residual heat of an autoclave of an aerated concrete block. refer to figure 1 , including sub-cylinder 4, autoclaving device, gas collecting pipeline 5 and recycling device. Autoclave comprises autoclave one 1, autoclave two 2 and autoclave three 3, sub-cylinder 4 is communicated with autoclave one 1, autoclave two 2 and autoclave three 3 respectively by steam pipeline, each Roots are equipped with valves on the steam pipes connected with the sub-cylinder 4. A first gas-down pipe 11 is connected between the autoclave one 1 and the autoclave two 2, a second gas-down pipe 12 is arranged between the autoclave one 1 and the autoclave three 3, the first gas-down pipe 11 and the second All valves are installed on the air pipe 12. Autoclave one 1, autoclave two 2 and autoc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com