Apparatus for surface treatment of pipelines and pipe fittings before using

A technology of front surface and pipe fittings, which is applied in the direction of metal material coating process, etc., can solve the problems that the processing speed of pipes and pipe fittings has a great influence on the construction progress, and the quality of pipe or pipe fittings affects the quality of the project, so as to achieve the benefit of pretreatment efficiency and shorten the time The effect of residence time and reducing the degree of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

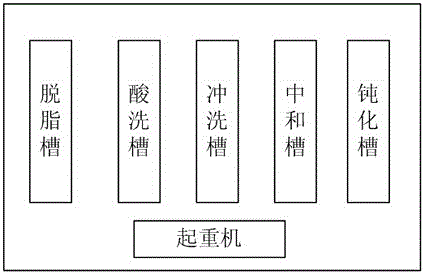

[0018] Such as figure 1 , a device for surface treatment of pipes and pipe fittings before use, including a pretreatment tank group, the pretreatment tank group includes degreasing tanks, pickling tanks, flushing tanks, neutralization tanks and passivation tanks, the degreasing tanks, acid The washing tank, rinsing tank, neutralization tank and passivation tank are arranged side by side according to the above order, and two gantry frames with fulcrums respectively located on the left and right sides of the pretreatment tank group are included. Each pretreatment tank in the pretreatment tank group is It is located below the crossbeam of the gantry frame, and a crane that can move along the length direction of the crossbeam is also arranged on the crossbeam.

[0019] In this embodiment, the degreasing tank, pickling tank, flushing tank, neutralization tank and passivation tank are arranged side by side and arranged in sequence, which facilitates the transfer of pipelines or pipe...

Embodiment 2

[0021] This embodiment is further limited on the basis of Example 1, as a kind of various pretreatment tanks suitable for on-site use and transfer, and has a good economic index in the small batch processing process, the degreasing tank, pickling The tank, rinse tank, neutralization tank and passivation tank are all strip tanks.

[0022] As an implementation method with low manufacturing cost and easy transshipment or reuse, the degreasing tank, pickling tank, flushing tank, neutralization tank and passivation tank are all iron tanks welded by metal plates.

[0023] To facilitate drying of pipes or fittings after or during pretreatment, a compressed gas outlet adjacent to the flush tank is also included.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com